Roller Shutter Roll Forming Machine Revolutionizing Security and Convenience

In the modern era, security and convenience have become paramount for both commercial and residential properties. Among the myriad of solutions available, roller shutters have emerged as a favored choice. Their effectiveness in providing security, privacy, and insulation has prompted widespread adoption across various sectors. Central to the production of high-quality roller shutters is the roller shutter roll forming machine, a sophisticated piece of machinery that has revolutionized the manufacturing process and set new industry standards.

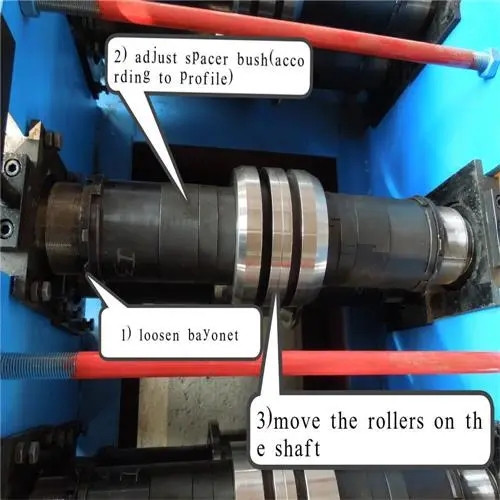

The roller shutter roll forming machine is designed to produce roller shutter slats from raw materials, typically galvanized steel or aluminum. The machine works through a series of rollers and dies that gradually shape and form flat metal sheets into designated profiles. This transformation occurs in stages, where the sheets pass through multiple sets of rollers, each meticulously crafted to impart specific features to the slats.

One of the key advantages of using a roller shutter roll forming machine is its efficiency. The process is highly automated, allowing for continuous production with minimal downtime. This not only increases the output but also ensures consistency in quality. The precision of the machine guarantees that every slat produced adheres to strict specifications, thus enhancing the overall performance of the roller shutters. This is particularly crucial in applications where security is a top concern, as even minor deviations in slat shape or size can compromise the integrity of the installation.

Additionally, the machine allows for customization, which is increasingly important in today’s market. Different businesses and homeowners have varying needs regarding the size, thickness, and finish of roller shutters. With advanced roll forming technology, manufacturers can easily adjust the machine settings to produce a range of slats to suit individual customer requirements. This flexibility not only meets diverse aesthetic preferences but also addresses functional demands such as thermal insulation and soundproofing.

Moreover, the roll forming process is known for its material efficiency. Unlike other manufacturing techniques that generate significant waste, roll forming optimally utilizes raw materials, contributing to sustainable practices within the industry. The precise nature of the machine means that less material is lost during production, and the end products have greater structural integrity.

An essential aspect of roller shutter roll forming machines is their integration with modern technology. Many machines now come equipped with advanced control systems that enhance the user experience. These systems allow operators to monitor production in real time, streamline settings for different projects, and even perform diagnostics to anticipate maintenance needs. Such innovations not only improve operational efficiency but also extend the lifespan of the machinery, offering manufacturers a comfortable return on investment.

Safety is another significant factor in the design and operation of roller shutter roll forming machines. Manufacturers prioritize the implementation of safety features to protect operators during the production process. This includes emergency stop mechanisms, safety guards, and real-time monitoring systems that ensure compliance with industry safety standards. By fostering a safe working environment, manufacturers can maintain productivity while safeguarding their workforce.

In the context of global demand for roller shutters, the roller shutter roll forming machine plays a crucial role in scaling production capacities. Manufacturers can respond quickly to fluctuating market demands due to the machine's ability to produce large volumes efficiently. This scalability not only supports local businesses but is also instrumental for exports, pushing companies to broaden their market reach.

In conclusion, the roller shutter roll forming machine stands at the forefront of modern manufacturing, merging efficiency, precision, and safety to create high-quality roller shutters. As businesses and homeowners increasingly recognize the importance of security and convenience, the demand for effective solutions will continue to rise. With advancements in technology and manufacturing processes, roller shutter roll forming machines will undoubtedly evolve to meet these challenges, driving the industry forward while ensuring that the needs of consumers are met with excellence. Whether for commercial storefronts or residential garages, the impact of these machines is profound, shaping the future of security solutions around the globe.