Roller Shutter Roll Forming Machine An Overview

In the realm of modern construction and security solutions, roller shutters have become an essential component for both commercial and residential properties. At the heart of roller shutter manufacturing is the roller shutter roll forming machine, a sophisticated piece of equipment designed to streamline the production process and ensure high-quality end products.

Functionality of the Roller Shutter Roll Forming Machine

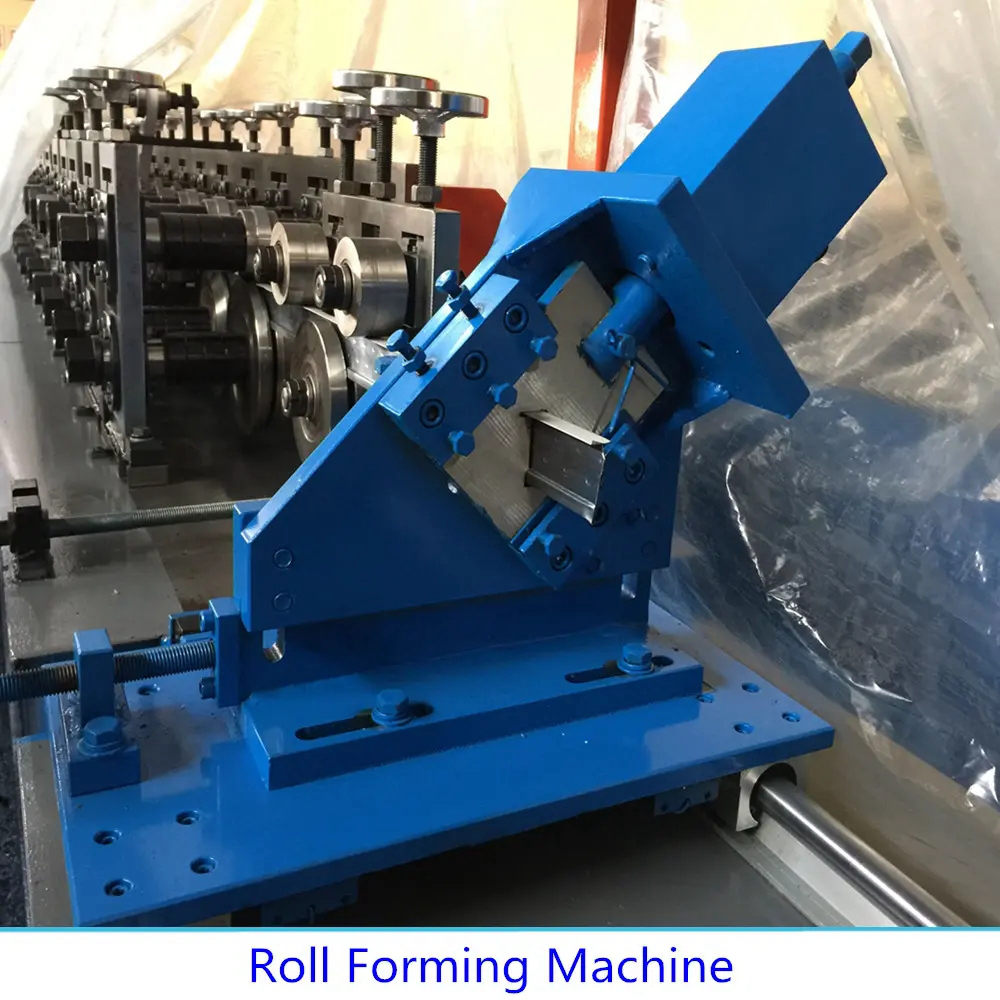

The roller shutter roll forming machine operates through a systematic process that involves the continuous bending and shaping of metal strips

. Typically made from materials such as galvanized steel or aluminum, these strips are fed into the machine, where they undergo a series of rollers that progressively shape them into the desired profile of the roller shutter. This method not only enhances precision but also maximizes material utilization, thereby minimizing waste.One of the key advantages of using a roll forming machine is its ability to produce consistent profiles. Unlike traditional methods, which may result in variances due to manual labor, a roll forming machine ensures that every shutter produced meets the predefined specifications. This level of consistency is crucial for manufacturers who prioritize quality and reliability in their products.

Customization and Versatility

Roller shutter roll forming machines are highly versatile and can be customized to produce a wide range of shutter designs. Manufacturers can adjust the setup to create different shutter thicknesses, widths, and styles, allowing for the production of everything from standard security shutters to bespoke solutions tailored to specific architectural needs. This adaptability makes the machines invaluable in an ever-evolving market.

Moreover, modern machines often feature advanced technology, including computer numerical control (CNC) systems, enabling automated operations and real-time monitoring. This enhances efficiency and reduces the risk of human error, further contributing to the overall quality of the manufactured shutters.

The Economic Impact

Investing in a roller shutter roll forming machine can yield significant economic benefits for manufacturers. The efficiency and speed of these machines can lead to higher production rates and reduced labor costs. By automating much of the manufacturing process, companies can operate with fewer resources while maintaining output levels, thereby increasing profitability.

Conclusion

In summary, roller shutter roll forming machines are at the forefront of roller shutter production. Offering precision, customization, and economic advantages, these machines are instrumental in meeting the demands of the construction and security industries. As technology continues to advance, the capabilities of roll forming machines will likely expand, promising even greater efficiencies and opportunities for manufacturers in the future. Embracing these innovations not only allows businesses to enhance their production capabilities but also positions them as leaders in a competitive marketplace.