Understanding Roller Shutter Door Slat Machines

Roller shutter doors are a popular choice for both commercial and residential properties due to their durability, security, and ease of use. The critical component of these doors is the slat, which is responsible for the door's structure and function. A roller shutter door slat machine is designed specifically to manufacture these slats, and understanding this machine's functionality and importance can help businesses optimize their production processes.

The Role of Roller Shutter Door Slat Machines

A roller shutter door slat machine automates the production of slats used in roller shutter doors. This machinery typically utilizes a series of rollers and molds to shape metal strips (often aluminum or steel) into slats that can be interlocked to form a continuous door. The precision involved in this process ensures consistent quality in the final product, which is vital for the security and performance of the roller shutter doors.

Key Components of Slat Machines

The design of a roller shutter door slat machine consists of various critical components, each having a unique role in the manufacturing process

1. Material Feeding System This system handles the raw metal strips, ensuring they are delivered to the machine smoothly and efficiently. It often includes mechanisms for straightening and cutting the material to the required lengths.

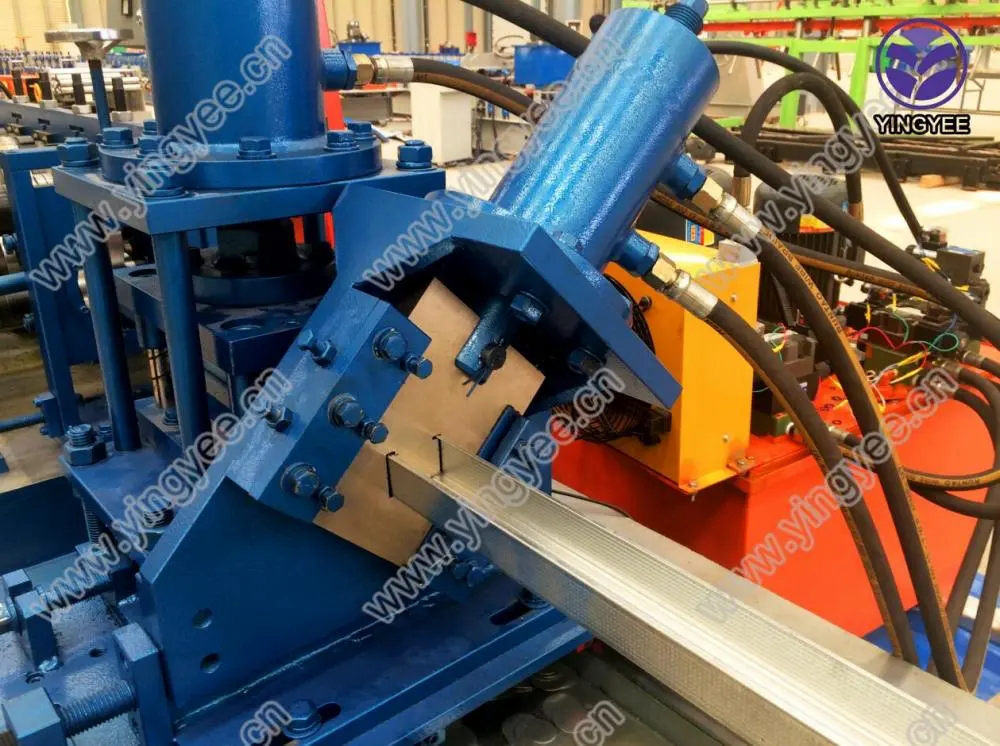

2. Forming Stations The heart of the slat machine, forming stations consist of rollers that bend and shape the metal into the desired slat profile. These stations are often adjustable, allowing manufacturers to produce different slat designs to meet varying customer specifications.

3. Cutting Mechanism Once the slats are formed, they need to be cut to the correct lengths. Some machines integrate an automatic cutting system that ensures each slat is uniform in size, enhancing the overall quality and reducing waste.

4. Stacking System After cutting, the slats are often stacked automatically to prepare them for packaging or further processing. Efficient stacking systems ensure that the workflow remains smooth and organized.

5. Control System Modern slat machines are equipped with advanced control systems that allow operators to monitor and adjust settings in real time. This technology improves efficiency, reduces the probability of errors, and makes it easier to keep production records.

Benefits of Using Roller Shutter Door Slat Machines

Investing in a roller shutter door slat machine offers numerous benefits for manufacturers

1. Increased Efficiency Automation drastically reduces the time taken to produce each slat compared to manual methods. This efficiency means businesses can fulfill larger orders within shorter timeframes.

2. Consistency and Quality Automated machines maintain a high level of precision in the slat production process. This consistency leads to fewer defects and a higher quality finished product.

3. Cost-Effectiveness While the initial investment in a roller shutter door slat machine may be significant, it can lead to long-term savings. The reduction in labor costs, material waste, and production time can outweigh the initial costs over time.

4. Versatility Many modern machines can be adjusted to produce different sizes and styles of slats, allowing manufacturers to meet diverse customer needs without significant downtime or reconfiguration.

5. Enhanced Safety Automation minimizes the direct involvement of workers in potentially hazardous tasks (like metal forming and cutting), leading to a safer work environment.

Conclusion

The roller shutter door slat machine plays a pivotal role in the roller shutter manufacturing industry. By understanding its components, functions, and benefits, manufacturers can make informed decisions when it comes to investing in this technology. As demand for security and efficiency continues to rise, the importance of high-quality roller shutter doors—and by extension, the machines that produce them—will undoubtedly grow. Incorporating advanced machinery into production lines will enhance operational efficiency, reduce costs, and deliver high-quality products to customers, cementing a business's position as a leader in this competitive market.