The Roller Shutter Door Making Machine Revolutionizing the Industry

In today’s fast-paced world, the demand for high-quality security solutions has skyrocketed, particularly in commercial and industrial sectors. One of the most sought-after products in this domain is the roller shutter door, known for its durability, security, and space-saving design. To meet the increasing demand for these efficient doors, the hardware industry has witnessed significant advancements in the technology and machinery used to manufacture roller shutter doors. Among these advancements, the roller shutter door making machine stands out as a game-changer.

Understanding Roller Shutter Doors

Roller shutter doors are versatile closures that roll up or down to secure an opening, making them ideal for warehouses, shops, garages, and many other applications. These doors provide excellent insulation and protection against burglary, weather conditions, and noise. The increasing popularity of roller shutter doors has prompted manufacturers to innovate and streamline the production process. This is where the roller shutter door making machine comes into play.

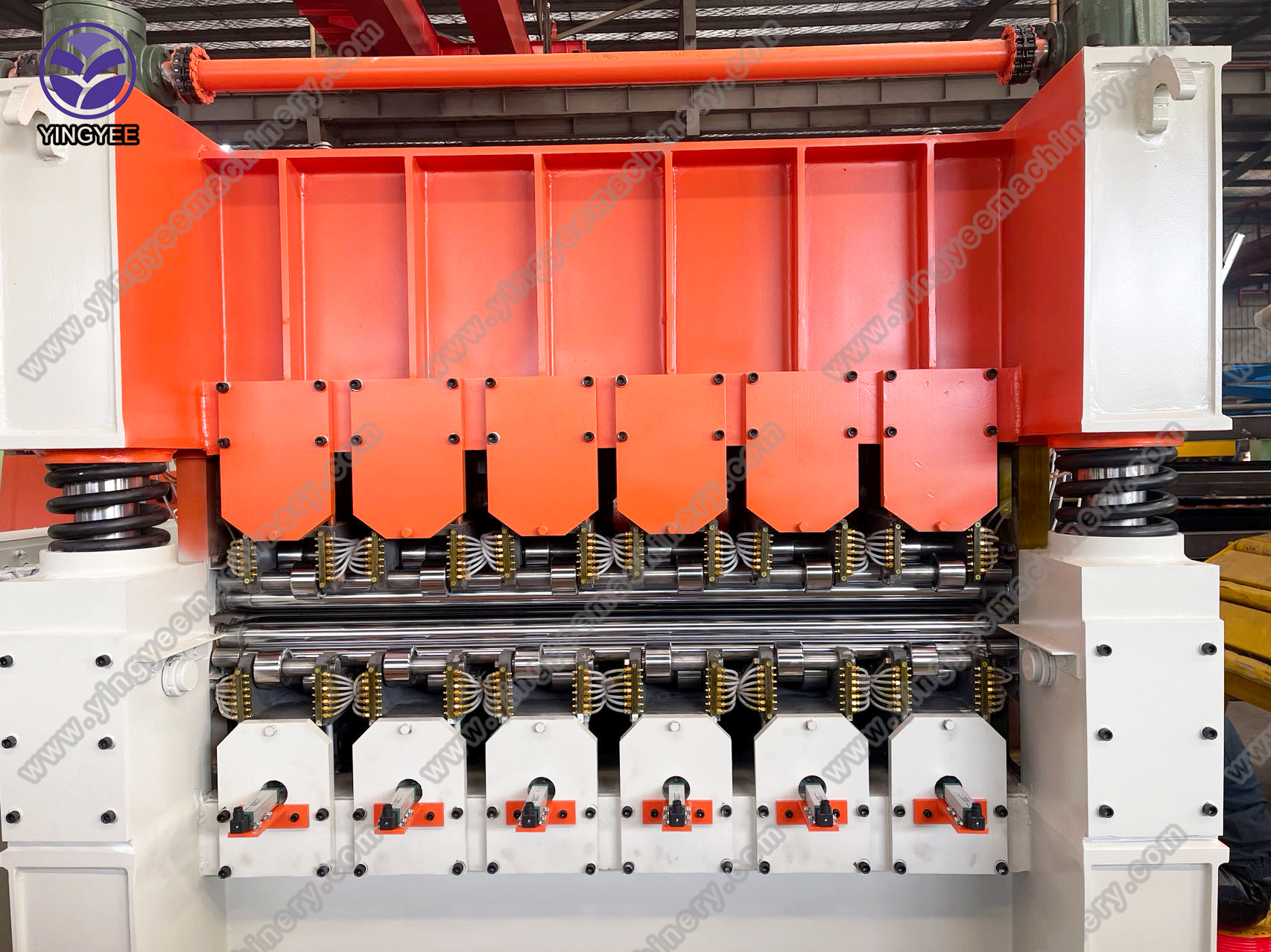

The Roller Shutter Door Making Machine

A roller shutter door making machine is specifically designed to manufacture roller shutter doors efficiently and consistently. This equipment automates the production process, significantly reducing the time and labor required to create each door. The machines can produce various types of roller shutter doors, including aluminum, steel, and vinyl, catering to diverse customer needs.

Incorporating modern technology, these machines often feature Computer Numerical Control (CNC) systems, which allow for precise cuts and shapes to be produced. This level of precision is crucial, as it ensures that every door meets the necessary specifications and quality standards. Furthermore, the machine’s ability to store design templates means that manufacturers can quickly switch between different door designs, enhancing versatility and reducing downtime.

Advantages of Using Roller Shutter Door Making Machines

1. Efficiency One of the primary advantages of using these machines is their efficiency. Manual production methods can be time-consuming and prone to human error. In contrast, roller shutter door making machines can produce doors at a much faster rate without compromising quality.

2. Cost-Effectiveness Although there is an initial investment in purchasing a roller shutter door making machine, the long-term cost savings are significant. With reduced labor costs and a lower rate of material wastage due to precision cutting, manufacturers can enjoy higher profit margins.

3. Customization Options Many modern machines come equipped with features that allow for customization in the manufacturing process. This means that manufacturers can easily create roller shutter doors tailored to specific customer requirements, such as unique sizes, colors, or functionalities.

4. High-Quality Production With advanced technology, these machines consistently produce high-quality products that meet industry standards. This reliability fosters customer trust and satisfaction, ultimately leading to repeat business and growth.

Conclusion

As the market for roller shutter doors continues to expand, the role of advanced manufacturing equipment like the roller shutter door making machine becomes increasingly important. By integrating automation, precision, and customization capabilities, manufacturers can meet the demands of an evolving market while maximizing efficiency and profitability.

In conclusion, investing in roller shutter door making machines is not just a trend but a strategic decision for manufacturers looking to upgrade their facilities and enhance their production capabilities. As the technology continues to evolve, we can expect even more innovative features to emerge, further revolutionizing the industry and setting new standards for roller shutter door production.