The Evolution and Benefits of Guardrail Roll Forming Machines

In today's fast-paced manufacturing landscape, the role of specialized machinery has become increasingly pivotal. Among these, guardrail roll forming machines stand out as essential equipment for producing safety barriers that are vital for road safety. These machines are not merely tools; they represent a significant evolution in how we approach road safety, infrastructure development, and manufacturing efficiency.

What is a Guardrail Roll Forming Machine?

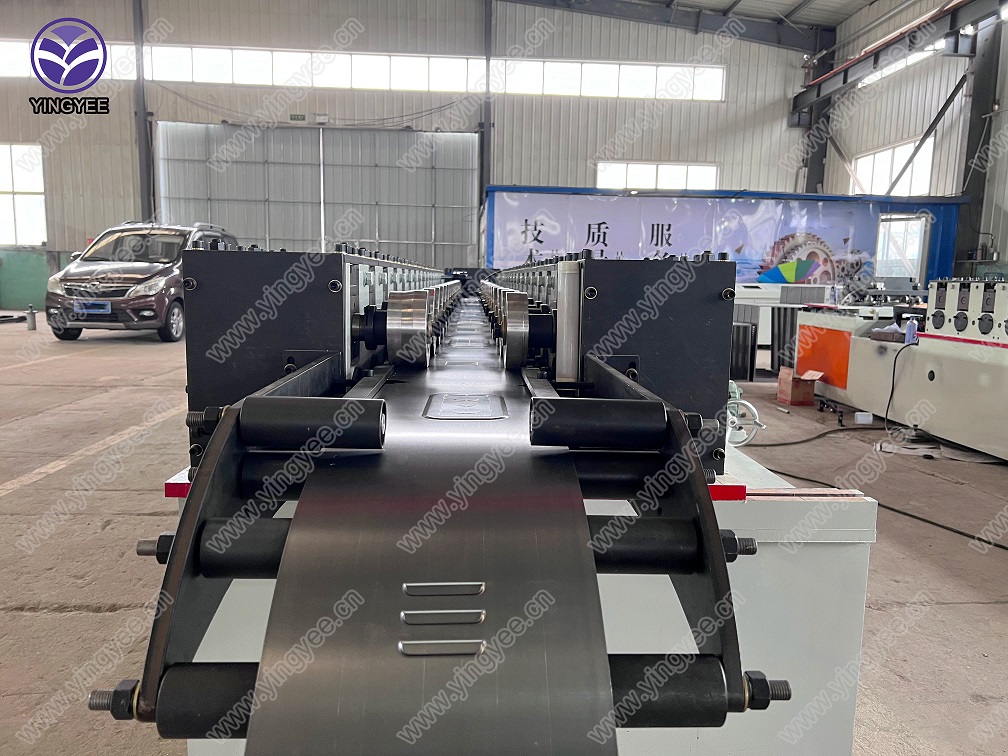

A guardrail roll forming machine is specialized equipment designed to process metal sheets into guardrails through a continuous bending operation. These machines utilize advanced technology to transform raw materials, such as galvanized steel, into high-quality guardrails with precise dimensions and strength. The roll forming process involves feeding metal sheets through a series of rollers that gradually shape the metal into the desired profile. Once formed, the guardrails are cut to length and can be further customized for specific applications.

The Importance of Guardrails

Guardrails serve a critical role in ensuring road safety. They are strategically placed along highways, bridges, and roadsides to prevent vehicles from veering off the roadway and into potentially dangerous areas, such as steep drops or oncoming traffic. Well-designed guardrails can significantly reduce the severity of accidents, ultimately saving lives and minimizing injuries. This highlights the importance of quality manufacturing in producing durable and reliable guardrails that can withstand harsh environmental conditions and vehicle impacts.

Benefits of Guardrail Roll Forming Machines

1. Efficiency and Automation Modern guardrail roll forming machines are highly automated, allowing for faster production rates compared to traditional manufacturing methods. This increased efficiency not only reduces labor costs but also maximizes output, enabling manufacturers to meet high demand with ease.

2. Precision Engineering The technological advancements in guardrail roll forming processes ensure that each product meets stringent quality standards. The machines can produce guardrails with highly accurate dimensions, ensuring a perfect fit and enhancing structural integrity.

3. Cost-Effectiveness By automating the manufacturing process, companies can significantly reduce operational costs. The ability to produce guardrails in large quantities also leads to economies of scale, ultimately lowering the price for consumers without sacrificing quality.

4. Material Versatility Guardrail roll forming machines can process various materials, including mild steel, stainless steel, and aluminum. This versatility allows manufacturers to cater to diverse market needs, whether for highway engineering projects, roadside works, or industrial applications.

5. Eco-Friendly Production As environmental concerns continue to grow, the manufacturing industry is focused on sustainable practices. Modern guardrail roll forming machines can efficiently utilize raw materials, minimizing waste generation. Many machines are designed to recycle scrap metal, further promoting eco-friendly practices in manufacturing.

6. Customization The ability to customize production runs according to specific project requirements is another significant advantage. Whether producing standard guardrail profiles or customized designs, these machines provide flexibility that is crucial in meeting diverse safety standards across different regions.

Conclusion

The guardrail roll forming machine factory represents a fusion of technology, efficiency, and safety in the manufacturing sector. As governments and organizations worldwide continue to prioritize road safety, the demand for high-quality guardrails is likely to rise. This trend underscores the importance of investing in advanced manufacturing technologies, such as guardrail roll forming machines, to ensure that safety standards are upheld while maintaining cost-effectiveness.

As we look to the future, the continuous evolution of guardrail roll forming technology will not only enhance production capabilities but also contribute significantly to global road safety initiatives. Investing in these advanced manufacturing solutions is not just a business decision; it is a commitment to protecting lives and fostering safer public infrastructure.