The Roller Shutter Door Forming Machine Revolutionizing Security and Convenience

In the ever-evolving world of construction and manufacturing, the roller shutter door forming machine stands out as a significant innovation. This advanced machinery is designed to produce roller shutter doors efficiently, addressing the needs for security, convenience, and aesthetics in various applications, from commercial buildings to residential properties.

Understanding the Roller Shutter Door

Roller shutter doors are a popular choice due to their robust security features and space-saving designs. These doors consist of horizontal slats that are rolled up and down, providing an effective barrier against intruders while allowing for easy access. They are commonly used in retail outlets, warehouses, garages, and even residential homes. The demand for roller shutter doors has surged, leading to the need for specialized manufacturing equipment to meet this growing market.

The Role of the Forming Machine

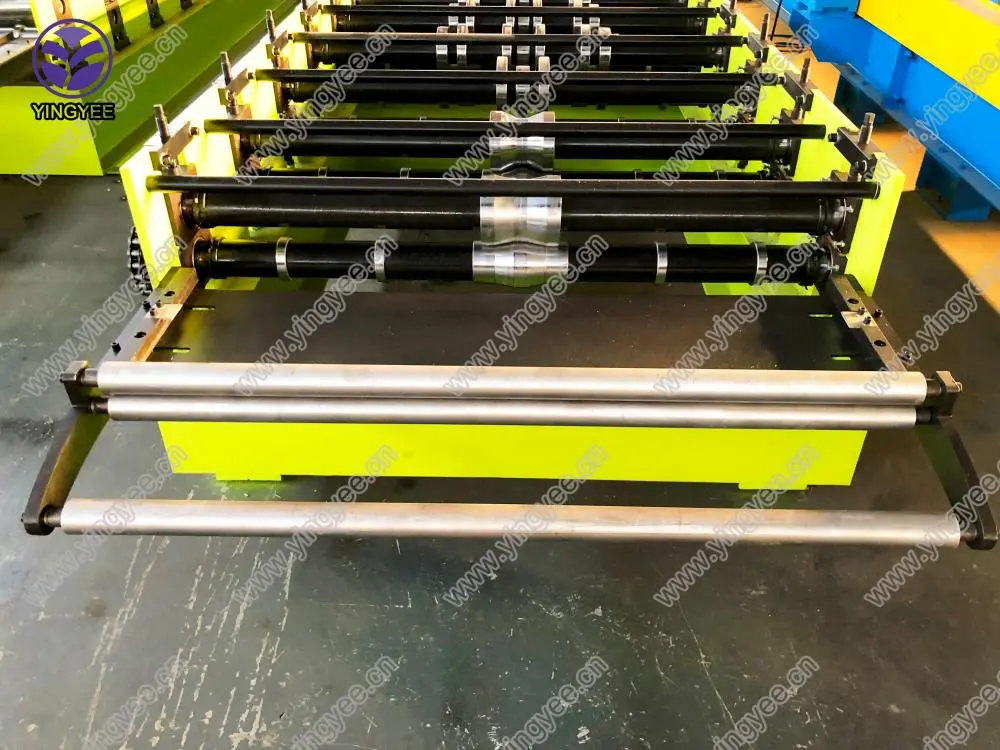

The roller shutter door forming machine automates the production process, ensuring high efficiency and consistent quality. The machine typically includes several components, such as a decoiler, roll forming unit, cutting system, and control panel. The process begins with a coil of metal sheet being fed into the decoiler. From there, the metal is shaped into slats using various rollers in the roll forming unit. The precise design allows for customization in terms of thickness, width, and pattern, catering to diverse customer preferences.

One of the standout features of a roller shutter door forming machine is its ability to produce doors at a rapid rate without compromising on quality. This high-speed production capability reduces labor costs and shortens lead times, making it an attractive investment for manufacturers. Additionally, modern machines are equipped with advanced technology, allowing for easily programmable operations and integration with other manufacturing systems.

Benefits of Roller Shutter Door Forming Machines

Investing in a roller shutter door forming machine comes with multiple benefits. Firstly, it allows manufacturers to respond swiftly to market demands, producing large volumes of doors while maintaining a variety of designs. Secondly, these machines enhance the overall quality of the finished product, as the automation minimizes human error and ensures uniformity. Lastly, the machinery often requires less manual intervention, reducing labor dependency and increasing safety on the production floor.

Conclusion

The roller shutter door forming machine is a game-changer in the manufacturing landscape. As security and convenience continue to be paramount in architectural design, the rise of these machines signals a robust future for businesses specializing in roller shutter doors. By embracing this technology, manufacturers can enhance their offerings, improve production efficiency, and ultimately contribute to safer and more functional environments. In a world where efficiency and quality are critical, these machines represent a prudent investment for forward-thinking manufacturers.