The Shelf Rack Upright Roll Forming Machine A Revolutionary Tool in Storage Solutions

In the world of industrial manufacturing and storage systems, the Shelf Rack Upright Roll Forming Machine stands as a testament to the power of technological innovation. This advanced machinery has transformed the way storage racks are produced, increasing efficiency, precision, and overall productivity in the process.

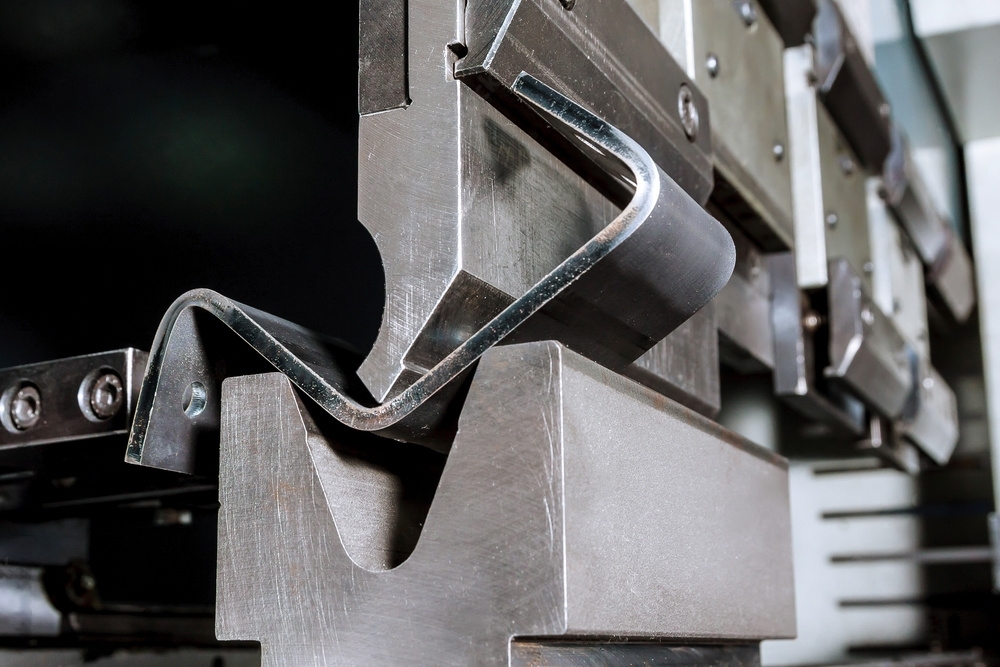

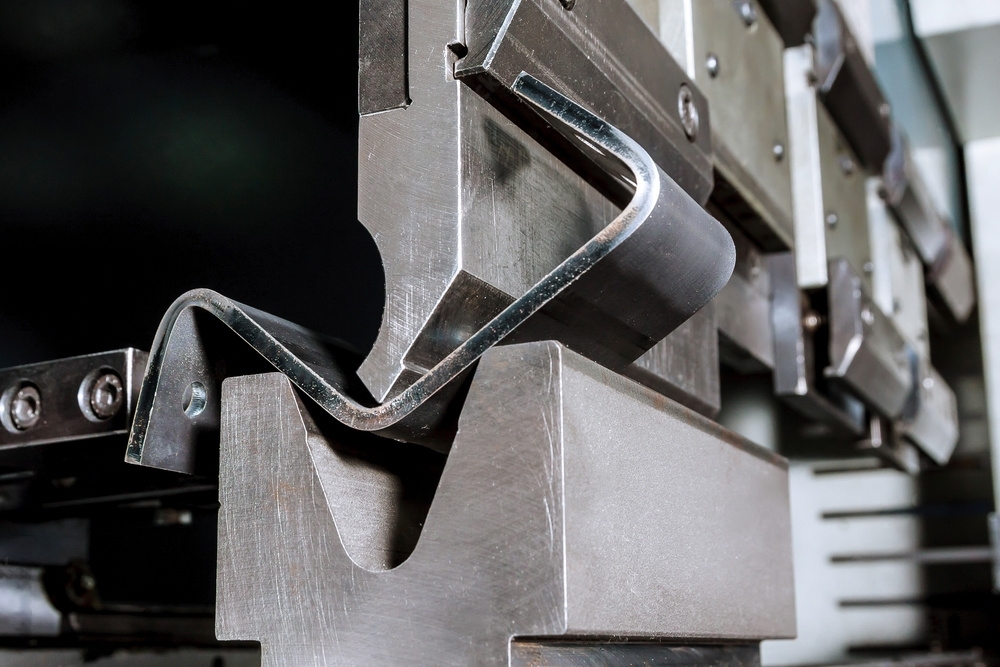

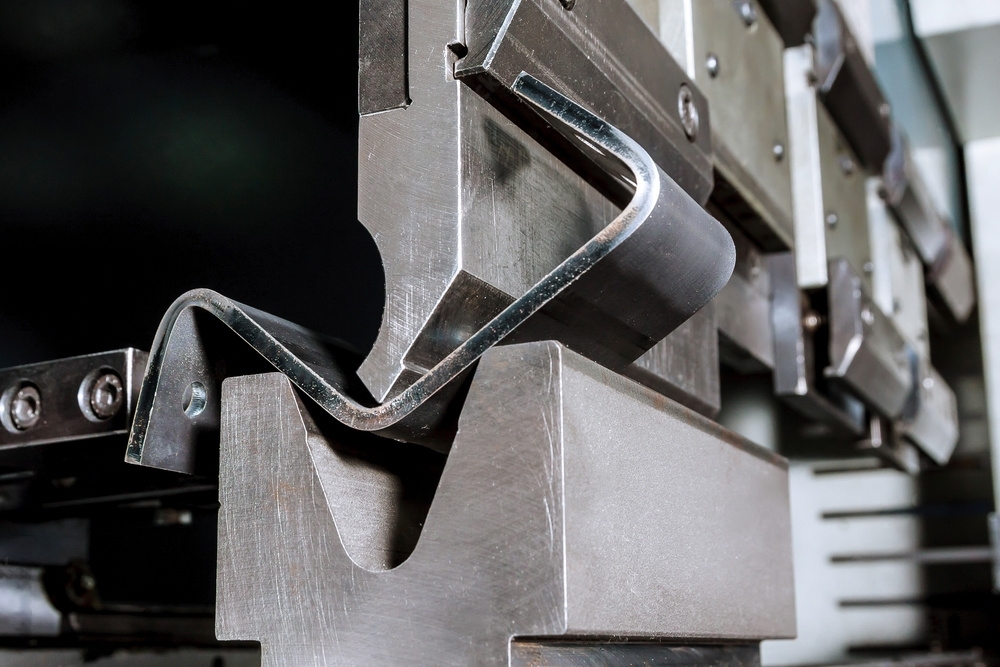

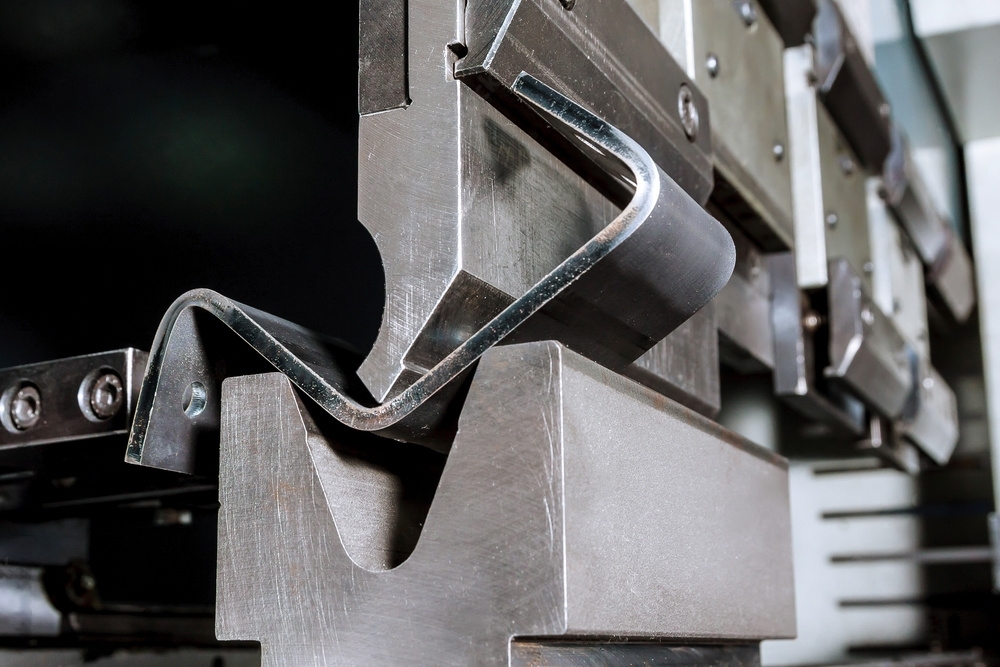

The shelf rack upright roll forming machine is a specialized piece of equipment designed specifically for the creation of vertical support structures, or uprights, used in warehouse shelving systems. The 'roll forming' process it employs involves a series of consecutive stations where metal strips are continuously bent into the desired shape through a set of precisely engineered rollers. This method offers a significant advantage over traditional fabrication techniques, such as cutting and welding, which can be time-consuming and labor-intensive.

The machine's operation is both seamless and efficient. It starts with raw steel coils that are fed into the machine, which then passes them through a series of roller dies. Each die shapes the metal incrementally, gradually forming it into the upright configuration required for the shelf racks. The process is highly automated, allowing for consistent quality and reduced production errors.

One key feature of the shelf rack upright roll forming machine is its versatility. It can produce various designs and sizes of uprights, catering to diverse storage requirements. From narrow aisle racking to heavy-duty industrial storage solutions, this machine can adapt to different specifications, making it a versatile asset for manufacturers From narrow aisle racking to heavy-duty industrial storage solutions, this machine can adapt to different specifications, making it a versatile asset for manufacturers

From narrow aisle racking to heavy-duty industrial storage solutions, this machine can adapt to different specifications, making it a versatile asset for manufacturers From narrow aisle racking to heavy-duty industrial storage solutions, this machine can adapt to different specifications, making it a versatile asset for manufacturers

shelf rack upright roll forming machine

shelf rack upright roll forming machine.

Moreover, the machine's high-speed operation significantly reduces production time, thereby increasing output and lowering costs. Its automation also minimizes human error, ensuring a higher level of precision in the final product. This not only enhances the structural integrity of the shelf racks but also extends their lifespan.

Beyond the manufacturing benefits, the shelf rack upright roll forming machine also contributes to sustainability efforts. By streamlining the production process and minimizing waste, it aligns with the growing trend of eco-friendly manufacturing practices.

In conclusion, the shelf rack upright roll forming machine is more than just a piece of equipment; it is a game-changer in the storage industry. It embodies the fusion of engineering excellence and technological advancement, revolutionizing the way storage racks are manufactured. Its impact is felt across the supply chain, from boosting manufacturer productivity to improving warehouse organization and efficiency. As we continue to push the boundaries of innovation, the shelf rack upright roll forming machine stands as a shining example of how technology can reshape an entire sector.

From narrow aisle racking to heavy-duty industrial storage solutions, this machine can adapt to different specifications, making it a versatile asset for manufacturers From narrow aisle racking to heavy-duty industrial storage solutions, this machine can adapt to different specifications, making it a versatile asset for manufacturers

From narrow aisle racking to heavy-duty industrial storage solutions, this machine can adapt to different specifications, making it a versatile asset for manufacturers From narrow aisle racking to heavy-duty industrial storage solutions, this machine can adapt to different specifications, making it a versatile asset for manufacturers shelf rack upright roll forming machine.

Moreover, the machine's high-speed operation significantly reduces production time, thereby increasing output and lowering costs. Its automation also minimizes human error, ensuring a higher level of precision in the final product. This not only enhances the structural integrity of the shelf racks but also extends their lifespan.

Beyond the manufacturing benefits, the shelf rack upright roll forming machine also contributes to sustainability efforts. By streamlining the production process and minimizing waste, it aligns with the growing trend of eco-friendly manufacturing practices.

In conclusion, the shelf rack upright roll forming machine is more than just a piece of equipment; it is a game-changer in the storage industry. It embodies the fusion of engineering excellence and technological advancement, revolutionizing the way storage racks are manufactured. Its impact is felt across the supply chain, from boosting manufacturer productivity to improving warehouse organization and efficiency. As we continue to push the boundaries of innovation, the shelf rack upright roll forming machine stands as a shining example of how technology can reshape an entire sector.

shelf rack upright roll forming machine.

Moreover, the machine's high-speed operation significantly reduces production time, thereby increasing output and lowering costs. Its automation also minimizes human error, ensuring a higher level of precision in the final product. This not only enhances the structural integrity of the shelf racks but also extends their lifespan.

Beyond the manufacturing benefits, the shelf rack upright roll forming machine also contributes to sustainability efforts. By streamlining the production process and minimizing waste, it aligns with the growing trend of eco-friendly manufacturing practices.

In conclusion, the shelf rack upright roll forming machine is more than just a piece of equipment; it is a game-changer in the storage industry. It embodies the fusion of engineering excellence and technological advancement, revolutionizing the way storage racks are manufactured. Its impact is felt across the supply chain, from boosting manufacturer productivity to improving warehouse organization and efficiency. As we continue to push the boundaries of innovation, the shelf rack upright roll forming machine stands as a shining example of how technology can reshape an entire sector.