W Beam Guard Rails Roll Forming Machine

Guardrails are an essential safety feature on roads and highways, preventing vehicles from veering off the road and into danger. One popular type of guardrail is the W beam guardrail, known for its strength and durability. To produce these guardrails efficiently and accurately, a roll forming machine is used.

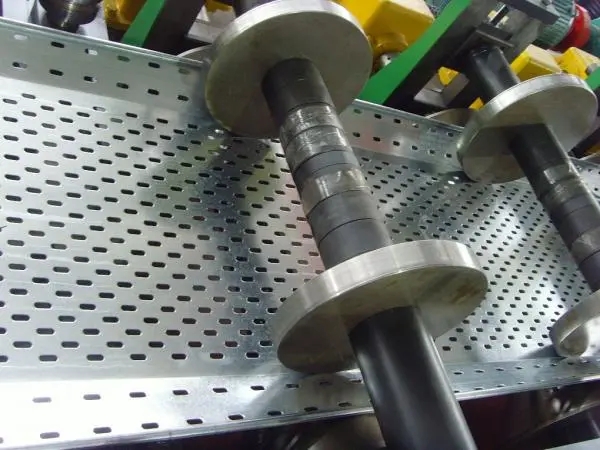

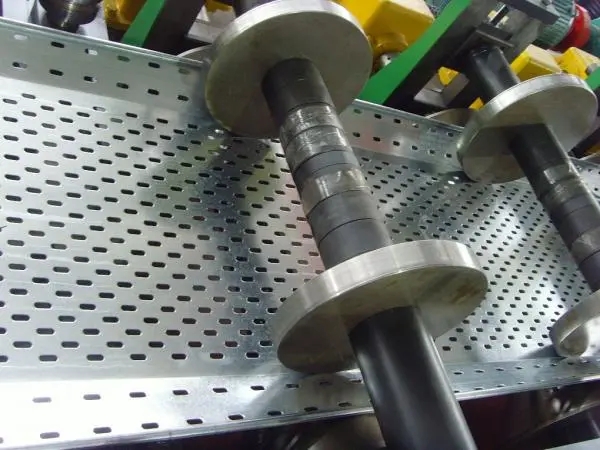

The W beam guardrail roll forming machine is a specialized piece of equipment designed to shape and cut metal sheets into the required profile for guardrails. The process begins with feeding a coil of metal sheet into the machine, which then passes through a series of rollers that gradually shape the metal into the desired W beam profile.

One of the key advantages of using a roll forming machine is its ability to produce guardrails in a continuous and uniform manner. This ensures consistency in the finished product, eliminating variations in shape and size that could compromise the safety and effectiveness of the guardrail. Additionally, the speed and efficiency of the roll forming process allow for large volumes of guardrails to be produced in a relatively short amount of time.

Another benefit of using a W beam guardrail roll forming machine is its versatility w beam guard rails roll forming machine

w beam guard rails roll forming machine. The machine can be easily adjusted to produce guardrails of different sizes and specifications, making it suitable for a wide range of projects and applications. This flexibility is especially important in the construction industry, where guardrails may need to be customized to meet specific requirements.

In addition to its efficiency and versatility, the W beam guardrail roll forming machine also offers cost savings for manufacturers. By automating the production process and reducing the need for manual labor, the machine helps to lower production costs and increase productivity. This, in turn, allows manufacturers to offer competitive pricing while maintaining high-quality standards.

Overall, the W beam guardrail roll forming machine plays a crucial role in the production of guardrails for roads and highways. Its efficiency, accuracy, and cost-effectiveness make it an indispensable tool for manufacturers looking to meet the growing demand for durable and reliable guardrail systems. As road safety continues to be a top priority, the roll forming machine will remain a key component in ensuring the safety of drivers and passengers around the world.