Rack upright roll forming machine is a critical piece of equipment used in the manufacturing industry. This machine is specifically designed to produce rack uprights, which are essential components of industrial storage systems. Here, we will explore the importance of rack upright roll forming machines and their role in the production process.

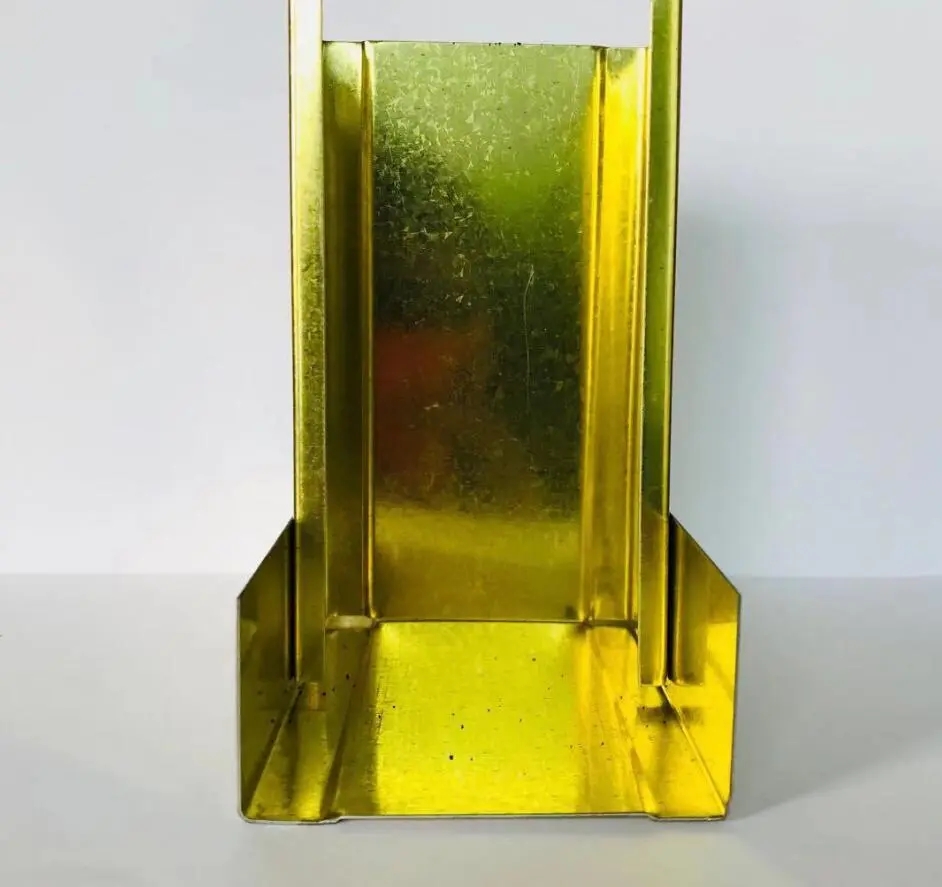

Rack uprights are vertical beams that are used to support shelves and provide structural integrity for storage racks. These racks are commonly found in warehouses, distribution centers, and other industrial facilities where efficient space utilization is crucial. Rack uprights are typically made from steel or aluminum due to their strength and durability.

The rack upright roll forming machine plays a crucial role in the manufacturing process of rack uprights. This machine utilizes a series of rollers to shape flat metal sheets into the desired profile of the rack upright. The rollers apply pressure to the metal sheet, causing it to bend and form into the correct shape. This process is repeated until the entire length of the metal sheet is transformed into a rack upright.

One of the key benefits of using a rack upright roll forming machine is its ability to produce rack uprights with high precision and consistency. The machine can create identical rack uprights quickly and efficiently, ensuring that each piece meets the required specifications. This level of accuracy is essential for ensuring that the rack uprights will fit properly and provide the necessary support for the storage system.

In addition to precision and consistency, rack upright roll forming machines also offer versatility in terms of the types of materials that can be used. These machines can accommodate a wide range of metal sheets with varying thickness and widths, allowing manufacturers to produce rack uprights in different sizes and configurations. This flexibility is essential for meeting the diverse needs of different industries and applications.

Furthermore, rack upright roll forming machines are known for their speed and efficiency in the production process. These machines can manufacture rack uprights at a much faster rate compared to traditional methods such as welding or cutting. This increased productivity not only helps manufacturers meet tight deadlines but also reduces overall production costs.

Overall, rack upright roll forming machines are essential equipment for manufacturers in the storage and logistics industry. These machines offer precision, consistency, versatility, and efficiency in the production of rack uprights, which are vital components of industrial storage systems. By utilizing rack upright roll forming machines, manufacturers can streamline their production process and ensure high-quality rack uprights that meet the demands of their customers.