Down pipe roll forming machine is an essential equipment used in the production of downpipes for drainage systems. This machine plays a vital role in shaping and forming the metal sheets into the desired downpipe profiles.

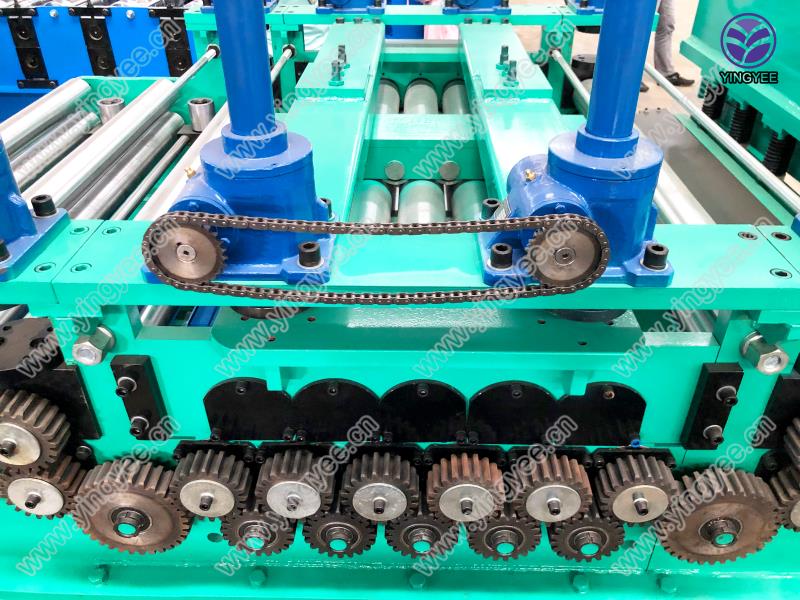

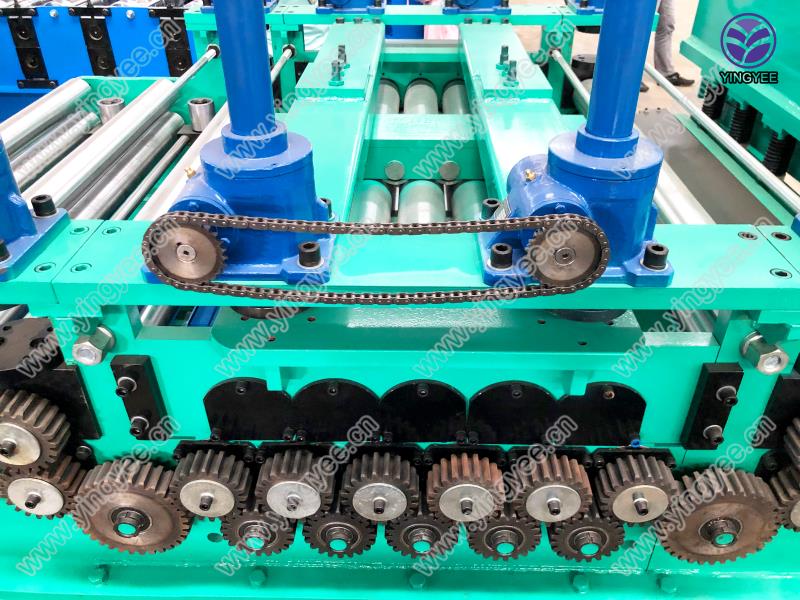

The process of roll forming involves passing a flat metal sheet through a series of rollers that gradually bend and shape the sheet into the desired cross-sectional profile. The down pipe roll forming machine is equipped with a set of rollers that are meticulously designed to create precise and consistent profiles. This ensures that the downpipes produced are of high quality and meet the required specifications.

One of the key advantages of using a down pipe roll forming machine is the efficiency and speed at which it can produce downpipes. Compared to traditional methods of fabrication, such as welding and molding, roll forming is much faster and requires minimal manual labor. This allows manufacturers to meet production targets more efficiently and reduce overall costs.

In addition, the down pipe roll forming machine is versatile and can be easily adjusted to produce different types and sizes of downpipes down pipe roll forming machine

down pipe roll forming machine. This flexibility makes it an ideal choice for manufacturers who produce a wide range of downpipe profiles for various applications. Whether it is a residential, commercial, or industrial project, the roll forming machine can quickly adapt to the specific requirements of the customer.

Furthermore, the down pipe roll forming machine ensures a high level of accuracy and consistency in the production of downpipes. The precision engineering of the rollers and the control systems in the machine guarantee that each downpipe is formed to the exact dimensions and specifications. This results in downpipes that fit seamlessly into the drainage system and perform effectively in channeling water away from buildings.

Overall, the down pipe roll forming machine is a crucial piece of equipment for manufacturers in the construction and building industry. Its ability to produce high-quality downpipes efficiently, accurately, and flexibly makes it an indispensable tool for meeting the growing demand for drainage solutions. With the advancements in technology and machinery, the roll forming process continues to evolve, offering even more capabilities and efficiencies for producing downpipes.