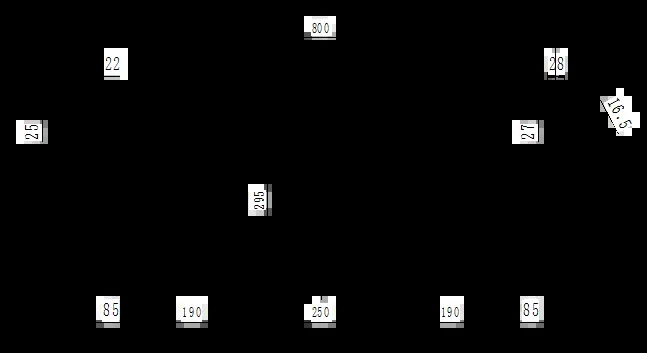

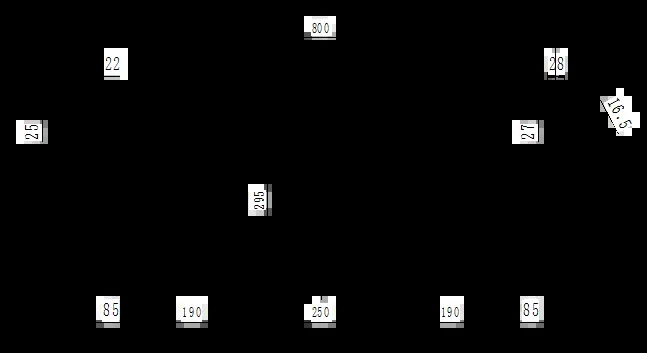

Roll forming is a widely used manufacturing process that involves continuously bending a long strip of metal into a desired shape. One key component of a roll forming machine is the tooling that guides the metal strip through the machine and shapes it into the final product. Two common types of tooling used in roll forming machines are T-bar and T-grid tooling.

T-bar tooling is used to create T-shaped profiles in the metal strip. The tooling consists of a series of rolls that bend the metal strip into the desired T-shape. T-bars are commonly used in the construction industry for applications such as framing and ceiling systems.

T-grid tooling is similar to T-bar tooling, but it is used to create a grid pattern in the metal strip. T-grid tooling is often used in the production of suspended ceilings, where the grid pattern provides support for ceiling tiles.

Both T-bar and T-grid tooling are essential components of a roll forming machine, and they must be carefully designed and manufactured to ensure accurate and consistent production t bar & t grid making roll forming machine

t bar & t grid making roll forming machine. The tooling must be precisely aligned and calibrated to ensure that the metal strip is formed correctly and to the desired dimensions.

In addition to the tooling, a roll forming machine also includes a series of rollers that progressively bend the metal strip into the desired shape. The metal strip is fed through the machine, passing through each set of rollers until it reaches the end of the machine, where it is cut to the desired length.

Roll forming machines are used in a wide range of industries, including automotive, construction, and appliance manufacturing. They are capable of producing a variety of profiles, including angles, channels, and tubes. Roll forming offers several advantages over other metal forming processes, including high productivity, cost-effectiveness, and the ability to produce complex shapes with tight tolerances.

Overall, T-bar and T-grid tooling are important components of a roll forming machine that enable the production of a wide range of metal profiles. By carefully designing and manufacturing the tooling, manufacturers can ensure accurate and consistent production of high-quality metal products.