The Importance of Road Safety Barrier Cold Bending Machines

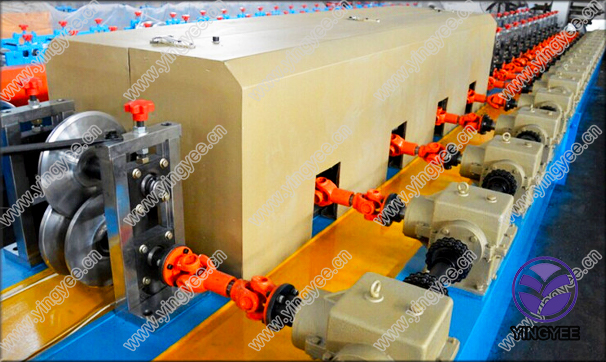

In the ever-evolving landscape of road safety, ensuring the effectiveness of safety barriers is paramount. One key player in the manufacturing process of these crucial structures is the cold bending machine. This specialized equipment facilitates the production of robust and durable road safety barriers through a precise and efficient bending process. Understanding the significance of cold bending machines in the context of road safety barriers is essential for both manufacturers and highway safety stakeholders.

The Importance of Road Safety Barrier Cold Bending Machines

One of the primary advantages of using cold bending machines in the production of road safety barriers is the consistency in quality. These machines are equipped with advanced technology that allows for precise control over the bending angle and curvature. As a result, manufacturers can produce barriers that meet specific regulations and standards required for highway safety. This level of precision not only enhances the durability of barriers but also ensures that they perform effectively in preventing accidents and reducing fatalities.

Moreover, cold bending machines contribute to the efficiency of the manufacturing process. Traditional bending methods, which may involve heating the metal, often require longer setup times and can lead to material waste due to overheating or distortion. Conversely, cold bending minimizes waste and can be executed quickly, allowing manufacturers to meet high demands while controlling costs. This efficiency translates into faster project turnaround times, ensuring that road safety measures can be implemented swiftly in response to emerging needs.

Investing in advanced cold bending technology is also a forward-thinking strategy for manufacturers aiming to stay competitive in the market. As road infrastructure continues to evolve with an increasing focus on safety, the demand for innovative barrier solutions is likely to grow. Companies that adopt modern cold bending machines can enhance their production capabilities, enabling them to experiment with new barrier designs that address various road safety challenges.

Additionally, robust safety barriers produced through these machines can positively impact public perception and trust in road infrastructure. Well-engineered barriers that effectively protect road users not only save lives but also contribute to a greater sense of safety and security on the roads. Consequently, governments and regulatory bodies are more inclined to endorse and invest in manufacturers who utilize high-quality production methods like cold bending.

In conclusion, the role of cold bending machines in the production of road safety barriers is critical. By providing consistency, efficiency, and the potential for innovation, these machines enhance the overall quality of safety measures on our roads. As we strive to improve road safety standards, embracing advanced manufacturing technologies will be instrumental in protecting lives and fostering safer driving environments. As the industry continues to advance, the importance of integrating state-of-the-art machinery into production processes will only become more pronounced.