Road Barrier and Guardrail Making Machines Ensuring Safety on Our Roads

Road safety has become an integral concern in today's world, where vehicle traffic has significantly increased. To mitigate the risks of accidents and enhance the safety of vehicles on highways and urban roads, road barriers and guardrails play a crucial role. The machines responsible for producing these safety features have advanced over the years, leading to improved designs, faster production, and more efficient use of materials.

The Importance of Road Barriers and Guardrails

Road barriers and guardrails are essential infrastructures designed to prevent vehicles from drifting off the road and to protect pedestrians and other road users. They serve multiple purposes

1. Safety Enhancement By minimizing the risks of collisions with fixed objects or unintended entry into hazardous terrains, barriers and guardrails significantly reduce the likelihood of severe accidents.

2. Traffic Control These structures guide vehicles along designated paths, particularly in areas with sharp turns or elevated roadways.

3. Structural Support On elevated highways and bridges, guardrails are critical for providing structural integrity by ensuring that vehicles do not veer off the edges.

4. Environmental Protection Barriers can also alleviate noise pollution and serve as a protective mechanism against wildlife, preventing animals from crossing into roadways.

As the demand for these safety features grows, the necessity of efficient and reliable manufacturing methods becomes paramount

. This is where road barrier and guardrail making machines come into play.Types of Machines Used in Manufacturing

There are several types of machines specifically designed for the production of road barriers and guardrails. These include

1. Roll Forming Machines These machines shape metal sheets into desired profiles by passing through a series of rollers. This method is efficient and provides uniformity in the production of guardrails.

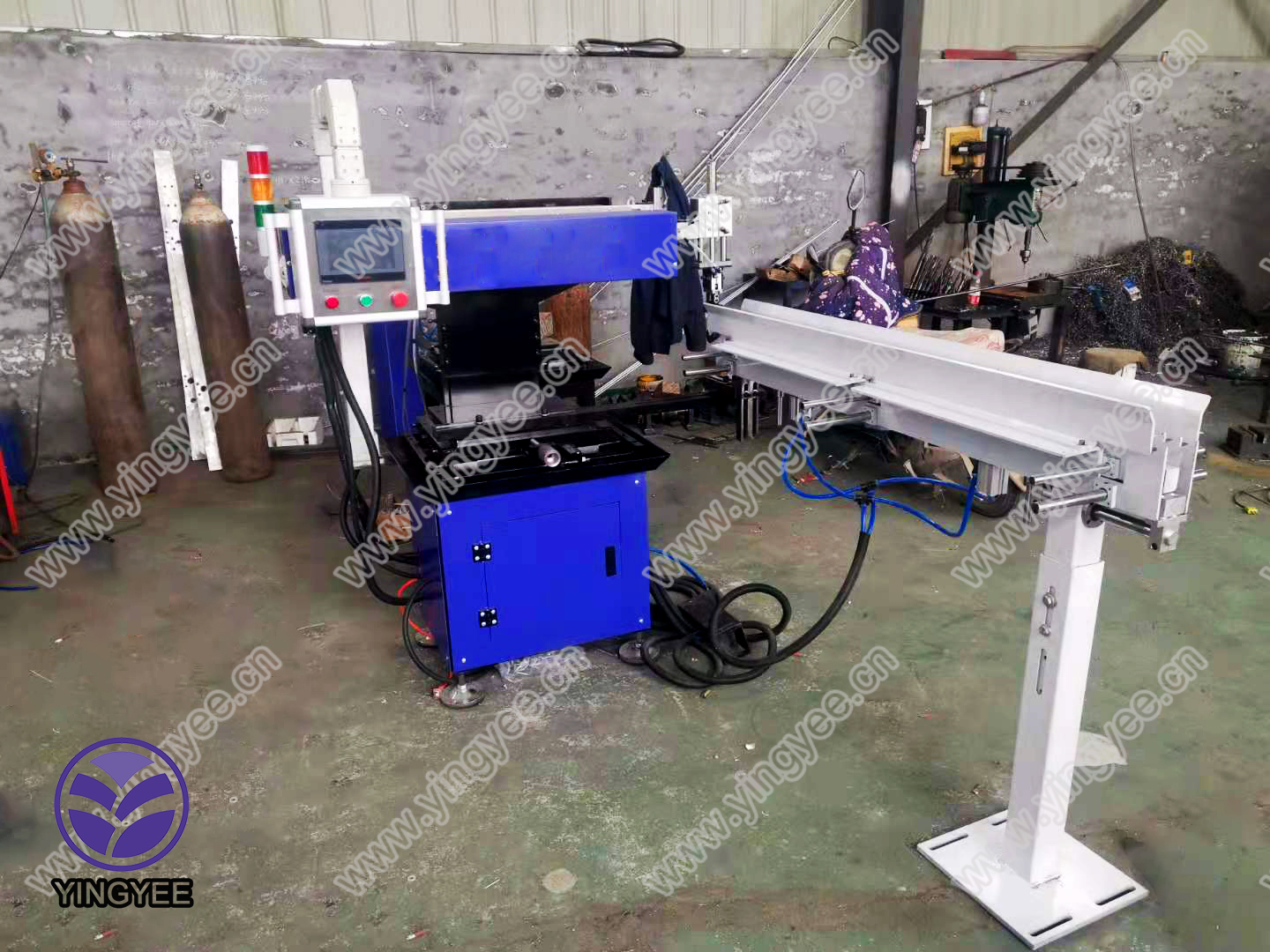

2. Cutting Machines Once the metal has been formed into the proper shape, cutting machines are utilized to produce pieces of specified lengths. Precision in this step is crucial to ensure that the sections fit together well during installation.

3. Welding Machines For certain barrier designs, components need to be welded together. Automated welding machines ensure strong and consistent joints, which are essential for the durability of the final product.

4. Coating Machines To improve corrosion resistance and enhance aesthetics, barriers and guardrails are often coated with protective paints or galvanization processes. Coating machines automate this process, ensuring even application.

5. Inspection and Quality Control Machines Quality assurance is critical in manufacturing road safety products. Advanced inspection machines check the integrity and measurements of the produced parts to ensure they meet industry standards.

The Technology Behind Production

Modern machinery utilizes advanced technologies such as Computer Numerical Control (CNC) to enhance precision and speed in manufacturing. CNC machines are capable of performing complex cutting and shaping tasks with minimal human intervention, leading to increased efficiency and reduced error rates.

Automation in manufacturing also allows for continuous production runs, which lowers labor costs and boosts output. The use of robotics in the production line can further streamline processes, reduce waste, and increase safety for workers on the shop floor.

Environmental Considerations

Given the growing focus on sustainability, many manufacturers are responding by adopting eco-friendly practices in the production of road barriers and guardrails. This includes using recycled materials for metal components and minimizing waste during the manufacturing process.

Moreover, environmentally safe coatings are being developed to reduce harmful emissions associated with traditional painting methods. Such innovations not only align with global sustainability efforts but also cater to a consumer base that increasingly values eco-friendly products.

Conclusion

The production of road barriers and guardrails is a vital industry that significantly contributes to road safety. The machines designed for this purpose have evolved through technological advancements, enhancing efficiency, precision, and sustainability. As traffic continues to increase and the importance of road safety becomes ever more evident, the need for high-quality road barriers and guardrails, along with the machines that make them, will remain paramount. By investing in innovative manufacturing technologies, we can ensure that our roadways are safer for everyone.