Right Channel Roll Forming Machine with High Straightness

In the pursuit of manufacturing efficiency and precision, the right channel roll forming machine stands out as an essential tool for producing high-quality structural components. With advancements in technology and engineering, the modern right channel roll forming machine is designed to achieve high straightness, ensuring that the end products meet the stringent demands of various industries.

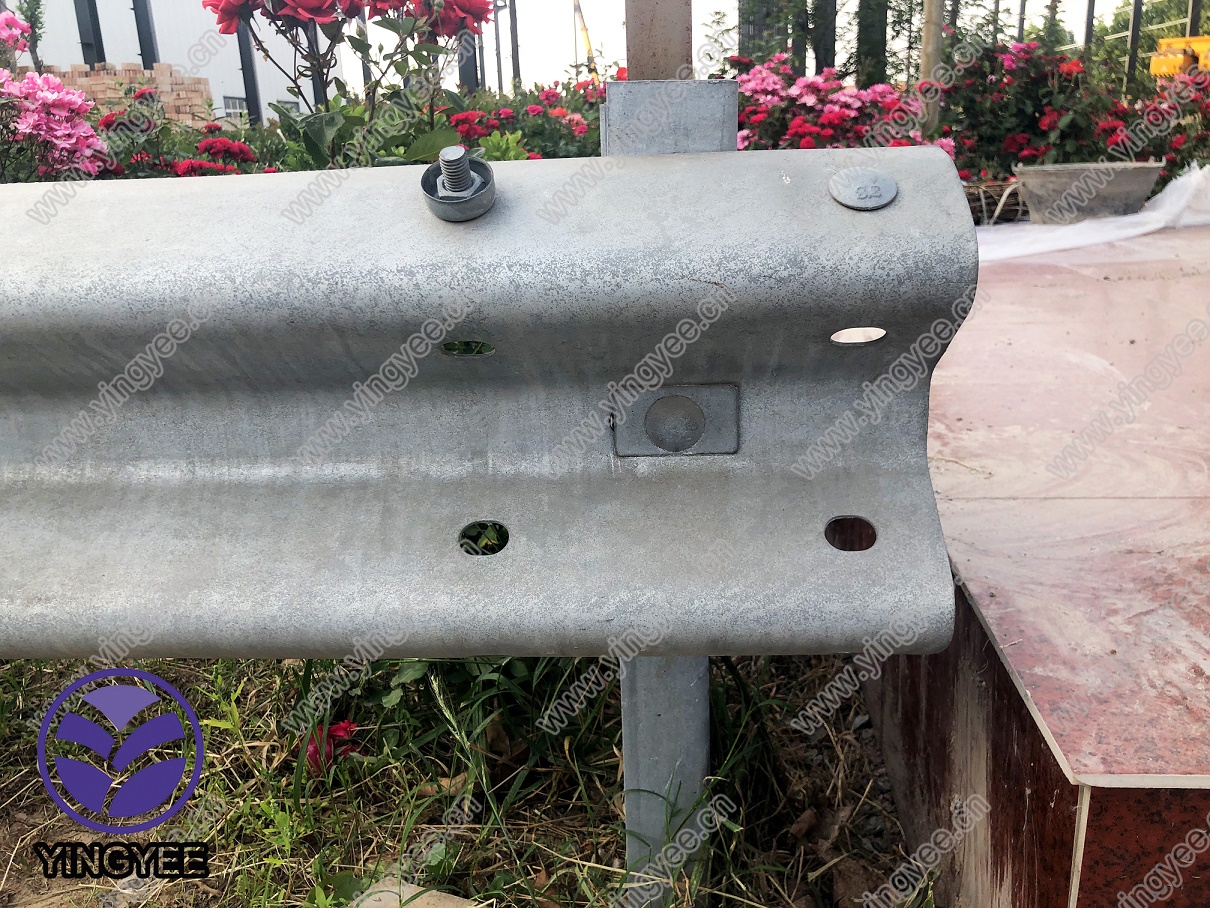

Roll forming is a continuous bending process in which a long strip of metal, usually coiled steel, is fed through a series of rollers to create specific cross-sectional shapes. The right channel, commonly used in construction, automotive, and various other industrial applications, is a structural element characterized by its unique C or U shape. To produce these shapes, manufacturers rely on roll forming machines that deliver accuracy and repeatability.

One of the key attributes of a high-quality roll forming machine is its ability to produce components with high straightness. Straightness is crucial because it directly affects the performance and aesthetics of the final product. If the channels are warped or bent, they may not fit properly during assembly, leading to structural integrity issues and increased labor costs for corrections. Therefore, machines designed to maintain high straightness are particularly valuable in ensuring that the formed channels meet industry specifications.

The design of a right channel roll forming machine includes several critical components that contribute to its performance. The rollers are crafted from high-strength materials and are precisely machined to ensure that they deliver consistent pressure and alignment throughout the forming process. Additionally, advanced control systems are often integrated into the machines to monitor and adjust parameters such as speed, pressure, and feed rate in real-time, which further enhances the straightness of the finished product.

Another significant feature of high-straightness roll forming machines is the use of automated cutting systems. These systems ensure that the formed channels are cut to exact lengths without deviation, preserving the overall straightness of the component. The integration of automated technology not only improves efficiency but also reduces human error, resulting in a more reliable manufacturing process.

Moreover, the benefits of investing in a right channel roll forming machine with high straightness extend beyond mere production quality. Companies that prioritize straightness and precision can enjoy lower production costs due to reduced waste and rework. Furthermore, the ability to produce consistently high-quality products enhances customer satisfaction and can lead to increased market competitiveness.

Training and expertise in the operation of these advanced machines are also essential. Operators should be familiar with the machine's settings and capabilities to optimize performance and troubleshoot any potential issues. Regular maintenance and calibration of the machines are crucial to uphold their precision and effectiveness, ensuring that high straightness is maintained over time.

In conclusion, the right channel roll forming machine with high straightness is a vital asset in modern manufacturing. As industries continue to evolve and demand higher quality products, the emphasis on straightness becomes even more critical. By investing in state-of-the-art roll forming technology, manufacturers can achieve greater efficiency, reduce costs, and enhance the overall quality of their outputs. In a competitive market, such advantages can define a company’s success, making the right channel roll forming machine a crucial component in the journey towards manufacturing excellence. The future of metal forming lies in precision, and high-straightness roll forming machines will undoubtedly play a pivotal role in that future.