The Ridge Cap Tile Roll Forming Machine An Essential Tool for Modern Roofing Solutions

In the realm of modern construction and architectural design, the demand for high-quality roofing materials is ever-increasing. One innovative solution that has emerged to meet this demand is the ridge cap tile roll forming machine. This highly specialized equipment not only streamlines the production of ridge caps but also enhances the quality and efficiency of roofing systems.

Understanding Ridge Cap Tiles

Ridge cap tiles are an essential component of any roofing structure. They serve to cover the ridge line where two slopes meet, providing a watertight seal that protects the interior of the building from rain and other weather-related damage. Additionally, ridge caps contribute to the overall aesthetic appeal of a roof, giving it a finished and polished look. With various materials like metal, clay, and concrete available, manufacturers prioritize creating designs that not only perform well but also offer visual appeal.

The Role of Roll Forming Machines

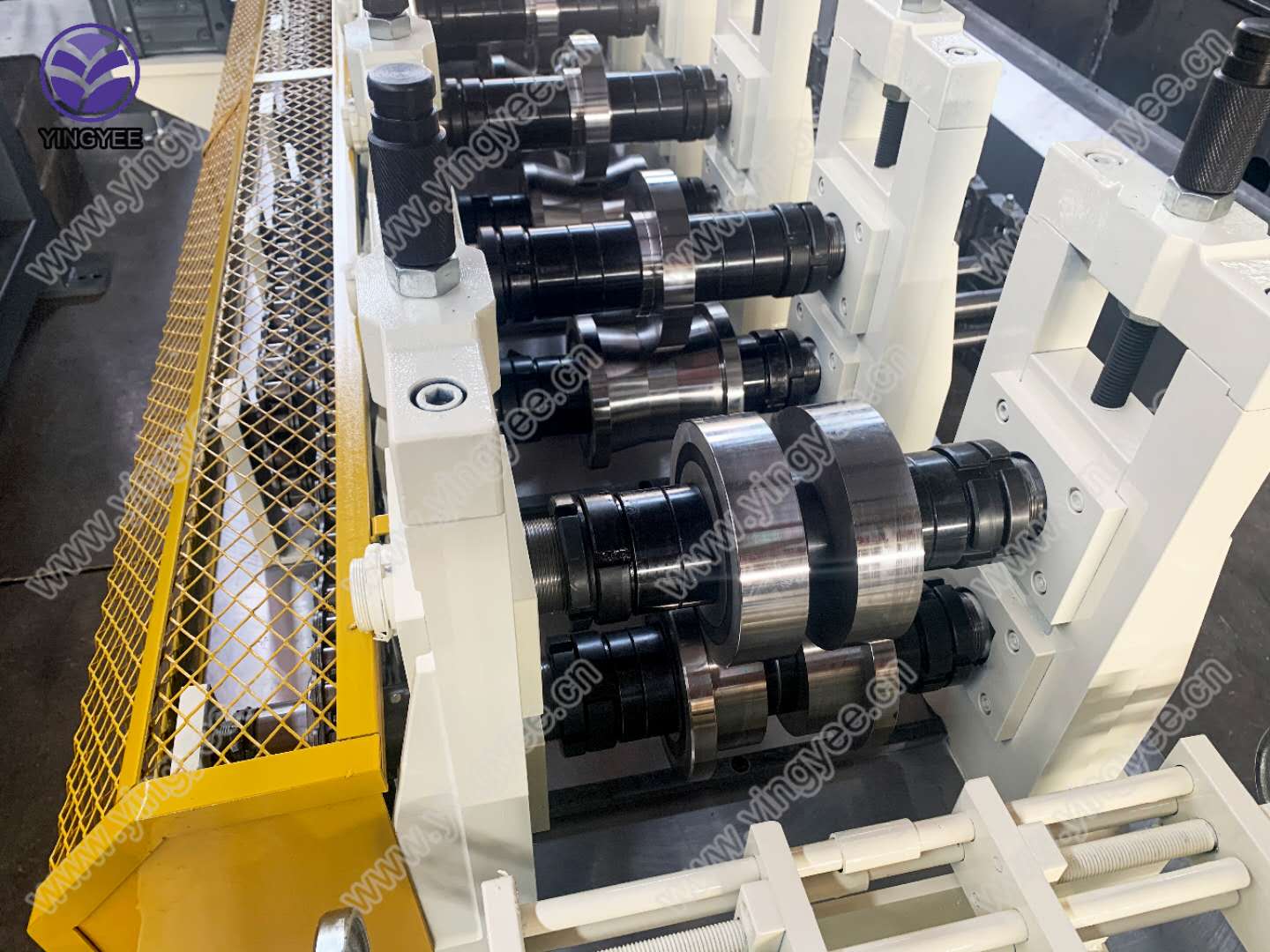

Roll forming is a continuous bending process in which a long strip of metal is passed through a series of rollers that progressively shape it into the desired cross-section. This method offers a cost-effective way to produce large quantities of roofing components like ridge caps with excellent precision and low waste. The ridge cap tile roll forming machine is specially designed to create ridges in a uniform manner, ensuring that each tile produced meets strict quality standards.

The process begins with the feeding of raw materials, which are typically sheets of metal, into the machine. These sheets are fed into a series of rollers that shape them into the desired profile. Modern ridge cap tile roll forming machines are equipped with digital controls that allow for precise adjustments, enabling manufacturers to accommodate various designs and dimensions easily.

Advantages of Ridge Cap Tile Roll Forming Machines

1. High Efficiency Traditional methods of producing ridge caps can be time-consuming and labor-intensive. The roll forming process significantly reduces production time, allowing manufacturers to meet tight deadlines and increasing overall output.

2. Consistency and Quality The automation of the roll forming process ensures that each ridge cap tile produced is uniform in thickness and shape. This consistency minimizes installation complications and ensures that roofing systems fit together seamlessly.

3. Material Versatility Most roll forming machines can handle a variety of materials, including galvanized steel, aluminum, and stainless steel. This flexibility allows manufacturers to adapt to changing market demands and customer preferences.

4. Cost-Effectiveness By minimizing waste and reducing labor costs, roll forming machines can lead to significant savings for manufacturers. This can translate to more competitive pricing for end consumers.

5. Customization Many modern ridge cap tile roll forming machines are designed to produce customized profiles. This adaptability allows manufacturers to offer unique designs that stand out in a crowded market, catering to specific architectural styles and client needs.

Maintenance and Operational Considerations

While ridge cap tile roll forming machines are built for durability, regular maintenance is crucial to ensure optimal performance. Routine checks on the rollers, lubrication systems, and electronic controls help prevent breakdowns and prolong the life of the equipment. Additionally, operator training is vital. Skilled operators can make adjustments on-the-fly, troubleshoot issues, and maintain the quality of the products produced.

Conclusion

The ridge cap tile roll forming machine is a game-changer in the roofing industry, providing an efficient and reliable method for producing essential roofing components. As the demand for high-quality and aesthetically pleasing roofing solutions continues to grow, the role of such machines will only become more prominent. Investing in advanced roll forming technology not only enhances productivity but also contributes to the overall quality and longevity of roofing applications. For manufacturers and contractors alike, embracing these advanced machines means staying ahead in a competitive market, ensuring that homes and buildings are not only structurally sound but also visually appealing.