Understanding Ridge Cap Roll Forming Machines

Ridge cap roll forming machines have revolutionized the metalworking and construction industries, providing efficient solutions for producing ridge caps for roofs. As essential components in modern building projects, ridge caps not only enhance the aesthetic appeal of structures but also contribute to their durability and weather resistance. This article delves into the functionality, significance, and technological advancements of ridge cap roll forming machines.

What is a Ridge Cap?

A ridge cap is a roofing component that covers the ridge of a roof, the highest point where two sloping sides meet. Its primary purpose is to seal the joint between the two roof surfaces, protecting against water ingress and wind uplift. Typically made from metals such as steel or aluminum, ridge caps come in various shapes and sizes to suit different roofing styles. The quality and fit of these caps are crucial for maintaining the integrity of the roofing system.

Role of Ridge Cap Roll Forming Machines

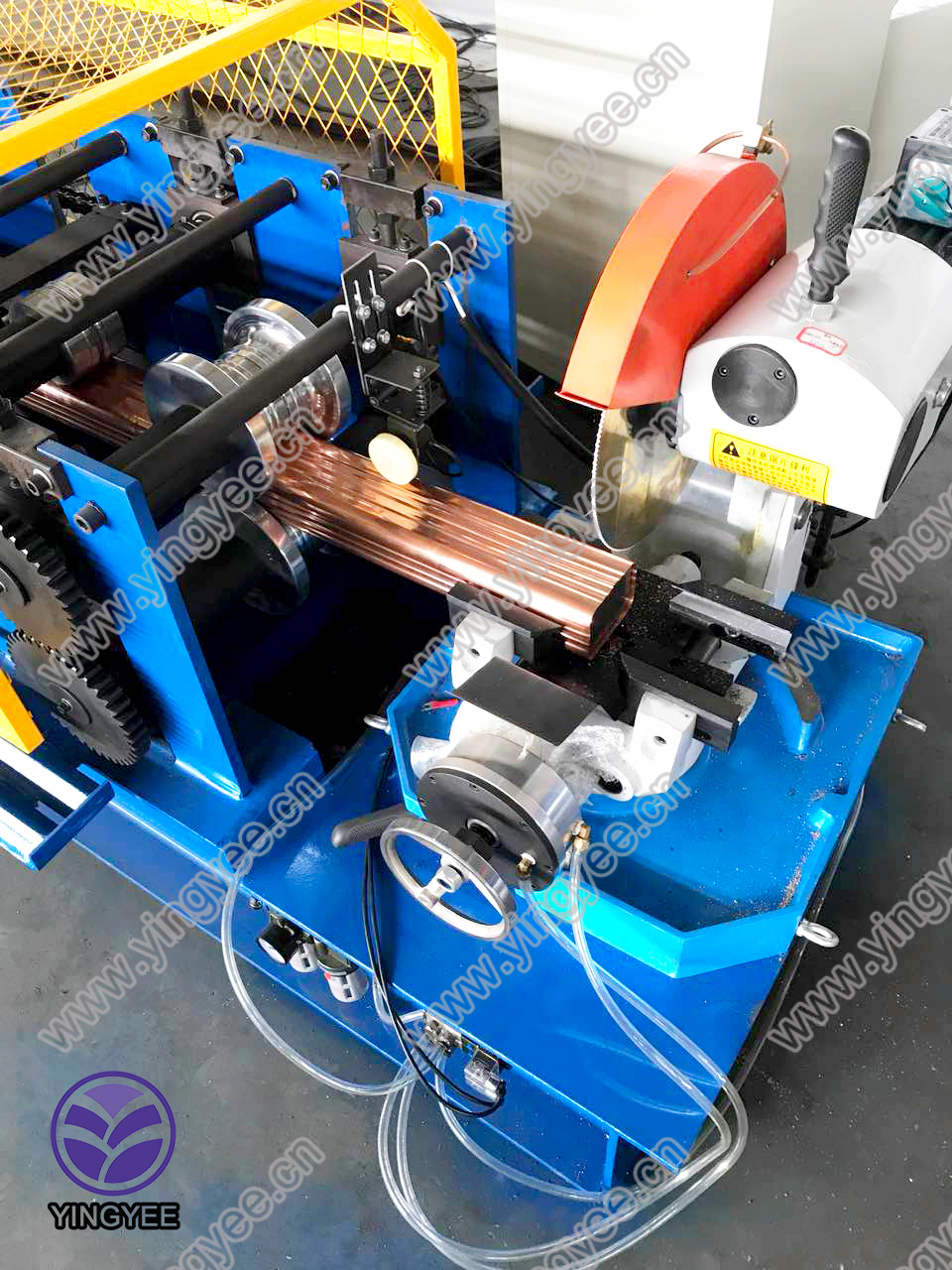

Ridge cap roll forming machines are specialized equipment designed to manufacture ridge caps from metal sheets. The roll forming process involves feeding a continuous strip of metal through a series of rollers that progressively shape the material into the desired profile. This method allows for high production rates and consistent quality.

The machines come equipped with advanced features such as programmable controls, which enable operators to easily adjust strip width, thickness, and profile shape. Additionally, the use of precision rollers ensures that the final products have uniform dimensions, reducing material waste and enhancing overall efficiency.

Advantages of Using Ridge Cap Roll Forming Machines

1. Efficiency Ridge cap roll forming machines can produce caps at a rapid pace, significantly reducing manufacturing time compared to traditional methods. This efficiency is particularly beneficial for large construction projects that require bulk orders of ridge caps.

2. Customization These machines offer the flexibility to create ridge caps tailored to specific architectural designs. Custom profiles can be produced quickly, accommodating the unique needs of various roofing styles.

3. Cost-Effectiveness By enabling manufacturers to produce components on demand, roll forming machines help reduce storage costs associated with pre-manufactured products. Furthermore, their ability to minimize scrap material contributes to lower production costs.

4. Durability and Strength Metal ridge caps produced through this process are known for their strength and longevity. The roll forming technique creates a robust product that can withstand harsh weather conditions, thus ensuring the roof's safety and functionality over time.

5. Sustainability With increasing emphasis on environmentally friendly practices, the efficiency of roll forming machines makes them a sustainable choice. The reduction of material waste and the longevity of the products contribute to a smaller carbon footprint in construction projects.

Technological Innovations

The evolution of ridge cap roll forming machines has been marked by significant technological advancements. Modern machines are now integrated with automation and digital technologies. Features such as computer numerical control (CNC) and automated material feeding systems enhance precision and reduce labor costs.

Additionally, some machines now come with online monitoring systems that can track production quality and efficiency in real-time. This integration of technology ensures that manufacturers can maintain high standards while optimizing their production processes.

Conclusion

Ridge cap roll forming machines have become indispensable tools in the construction and roofing industries. Their ability to produce durable, customized ridge caps with remarkable efficiency positions them at the forefront of modern manufacturing technology. As more builders and manufacturers recognize the importance of quality roofing components, the demand for advanced roll forming machines is likely to continue growing.

In summary, the significance of ridge cap roll forming machines extends beyond mere production capabilities; they represent a shift towards more efficient, cost-effective, and sustainable building practices in a rapidly evolving industry.