Ridge Capping Roll Forming Machines An Overview

Ridge capping is an essential component of roofing systems, particularly in regions prone to heavy rainfall or snowfall. The ridge cap serves as the final component that seals the ridge of a roof, preventing water ingress and ensuring durability. To produce high-quality ridge caps efficiently, manufacturers often turn to ridge capping roll forming machines. These innovative machines facilitate the production of precision-engineered ridge caps that cater to various roofing requirements.

The Functionality of Ridge Capping Roll Forming Machines

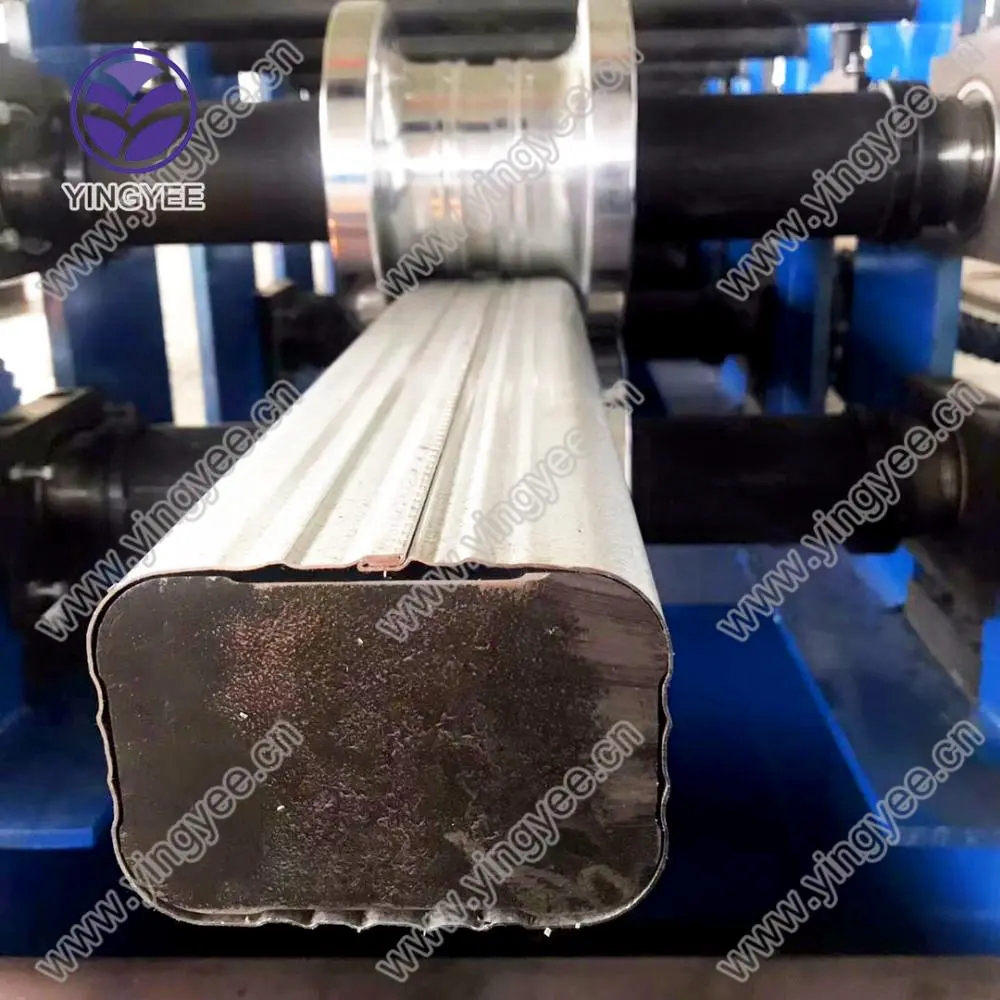

Ridge capping roll forming machines are designed to transform flat metal sheets into shaped ridge caps through a continuous forming process. The process typically begins with the feeding of metal sheets—usually galvanized steel, aluminum, or stainless steel—into the machine. As these sheets pass through a series of rollers, they are gradually shaped into their final form, ensuring uniformity and strength.

The machines can be customized to produce a variety of ridge cap profiles, allowing manufacturers to meet specific architectural and aesthetic demands. The roll forming process is highly efficient and can produce long lengths of ridge caps with minimal waste—an essential consideration in today’s environmentally conscious market.

Advantages of Using Roll Forming Technology

1. Cost-Effectiveness Ridge capping roll forming machines significantly reduce labor costs and material waste. With automation and precision engineering, manufacturers can produce ridge caps at a lower cost per unit compared to traditional manufacturing methods.

2. Consistency and Quality The automation included in roll forming machines ensures consistent thickness and size in each ridge cap produced. This uniformity translates into better sealing and performance when installed on roofs, which can enhance the building's longevity and structural integrity.

3. Versatility These machines can be configured to create various profiles and sizes, making them suitable for different roofing applications. Whether the requirement is for residential buildings, commercial establishments, or industrial complexes, ridge capping roll forming machines can adapt to meet the producers' needs.

4. Speed Roll forming machines are capable of operating at high speeds, allowing manufacturers to keep up with high-demand production schedules. This speed translates to increased output and shorter lead times, giving businesses a competitive advantage.

Applications in the Roofing Industry

Ridge capping produced by roll forming machines is used across multiple sectors. In residential roofing, they are commonly installed on gable roofs, providing a finished appearance while protecting the roof structure from environmental elements. In commercial buildings, ridge caps play a critical role in overall roofing system performance, enhancing durability and energy efficiency.

Additionally, the architectural versatility of ridge capping allows for creative designs, where manufacturers can produce custom profiles that cater to specific visual and functional requirements. This adaptability has made ridge capping roll forming machines indispensable in modern roofing production.

Conclusion

In the competitive world of roofing and building construction, the efficiency and precision of ridge capping roll forming machines make them a valuable asset. By streamlining the production process, ensuring consistency in quality, and accommodating various types of designs, these machines contribute significantly to the roofing industry's advancement. As technology continues to develop, the capabilities of ridge capping roll forming machines are likely to expand, further enhancing their role in creating robust and aesthetically pleasing roofing solutions. Manufacturers looking to invest in roofing production equipment should seriously consider the benefits offered by ridge capping roll forming machines, as they are pivotal in achieving operational efficiency and high-quality outputs in the roofing market.