The Importance of Rain Gutter Roll Forming Machines

In the construction and renovation industry, effective water management is crucial to the longevity and integrity of buildings. One key component in this water management system is the rain gutter, which directs rainfall away from roofs, foundations, and walls, reducing the risk of water damage. To meet the demand for durable and efficient rain gutters, manufacturers rely on specialized equipment known as rain gutter roll forming machines.

Understanding Rain Gutter Roll Forming Machines

A rain gutter roll forming machine is a type of machinery that fabricates metal sheets into the desired shape for rain gutters. This process involves using a series of rollers that gradually shape a flat metal strip into a continuous profile that can be installed along the edges of roofs. The formation of these gutters is not only about functionality; it also involves aesthetics, as gutters can be designed in various styles and finishes to complement the architecture of a building.

Functionality and Efficiency

The primary advantage of using a rain gutter roll forming machine is efficiency. These machines can produce gutters at high speeds, making it possible to meet large-scale demand while maintaining consistent quality. The automation of the roll forming process minimizes human error, ensuring that each gutter is manufactured to precise specifications. Furthermore, modern machines often integrate advanced technologies, such as computer numerical control (CNC), allowing for programmable adjustments to accommodate different gutter profiles and sizes.

Material Versatility

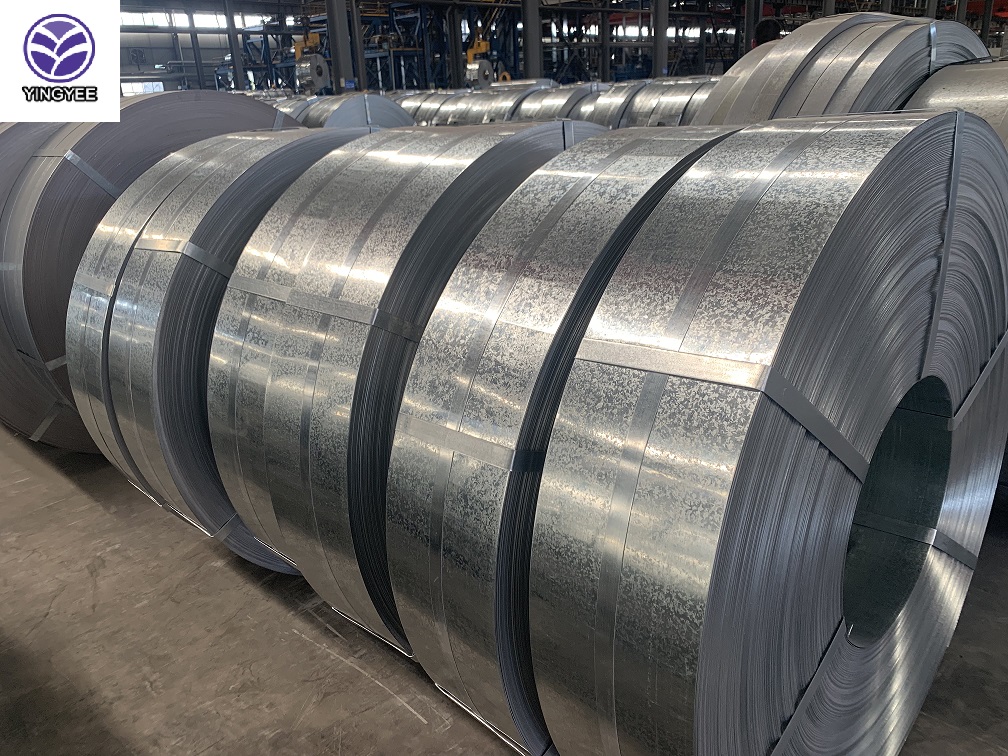

Rain gutter roll forming machines are typically used with a variety of materials, including galvanized steel, aluminum, copper, and stainless steel. Each of these materials offers distinct advantages; for instance, copper gutters are known for their durability and aesthetic appeal, while aluminum gutters are lightweight and resistant to corrosion. The flexibility of the machines to handle various materials allows manufacturers to cater to different market needs and consumer preferences, enhancing their competitive edge.

Customization and Adaptability

One of the essential features of rain gutter roll forming machines is their ability to produce customized gutters. The machines can be designed to accommodate specific profiles based on client requirements or regional building codes. This adaptability is crucial, especially in regions where certain gutter designs are preferred due to climatic conditions. By providing customized solutions, manufacturers can tap into niche markets and establish stronger relationships with their clients.

Environmental Considerations

As the construction industry moves towards more sustainable practices, rain gutter roll forming machines play a role in this transition. Using recyclable materials and optimizing the manufacturing process can significantly reduce waste. Additionally, efficient water drainage systems like well-designed gutters can help mitigate water runoff issues, contributing to broader environmental efforts. Manufacturers that invest in eco-friendly technologies and materials can not only reduce their carbon footprint but also appeal to environmentally conscious consumers.

Conclusion

In conclusion, rain gutter roll forming machines are indispensable tools in the modern construction industry. They enhance efficiency, facilitate customization, and support material versatility. As water management continues to be a critical concern in building design, the role of these machines is set to grow. Manufacturers who utilize advanced roll forming technologies will not only be able to meet the demands of their customers but also contribute to sustainable building practices. The evolution of rain gutter production is a perfect example of how technology can improve traditional practices and adapt to the changing needs of the industry. As we look to the future, the advancements in rain gutter roll forming machinery will undoubtedly play a vital role in shaping functional, aesthetically pleasing, and environmentally friendly building solutions.