Quick Changeable C/Z Purlin Roll Forming Machine Revolutionizing Construction Efficiency

In the fast-evolving world of construction, efficiency and adaptability are key. One of the innovative solutions that have emerged in this sector is the quick changeable C/Z purlin roll forming machine. This advanced technology is designed to enhance the production of purlins — essential structural components in steel buildings — while significantly reducing downtime and improving flexibility in manufacturing.

Understanding C/Z Purlins

C/Z purlins are horizontal members used in steel buildings to support roof and wall sheeting. The distinction between the two lies in their shape; C purlins are shaped like a ‘C’, whereas Z purlins are shaped like a ‘Z’. Both types serve similar functions but can be utilized in different contexts based on structural requirements, load conditions, and design preferences. Their lightweight yet strong characteristics make them ideal for modern construction, contributing to efficient frameworks that support roofs and walls.

The Need for Quick Changeability

Traditional roll forming machines often require significant time and labor to switch from producing C purlins to Z purlins. This process typically involves changing tooling, recalibrating the machine, and conducting test runs to ensure product quality. As a result, production times can be notably longer, leading to increased costs and delays for contractors and builders.

The quick changeable C/Z purlin roll forming machine addresses this challenge by allowing rapid transitions between different profiles. This capability minimizes downtime and streamlines operations, making it particularly valuable for companies that need to respond swiftly to changing project demands or varying client specifications.

Key Features of Quick Changeable Roll Forming Machines

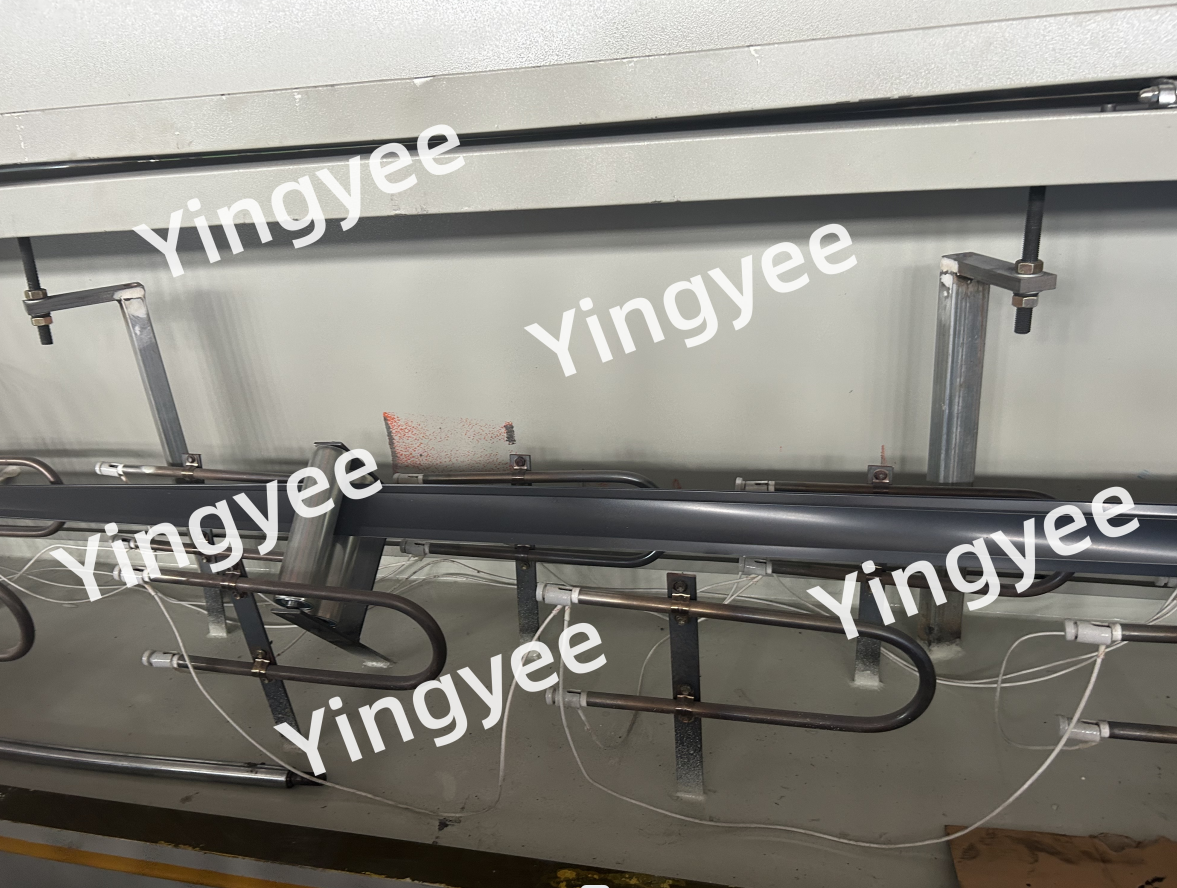

1. Modular Design The machine features a modular design that allows for the quick replacement of components. This means that switching between C and Z profiles can be accomplished in a matter of minutes, rather than hours, facilitating a more dynamic production schedule.

2. Automated Settings Many modern machines are equipped with computerized controls, enabling automated adjustments to the machine settings. This technology reduces the likelihood of human error and ensures consistent quality across different purlin profiles.

4. Space Efficiency With a more compact design compared to traditional machines, quick changeable roll forming machines occupy less factory floor space. This is particularly advantageous for small to mid-sized enterprises that may have limited workshop space.

5. Versatility The ability to produce both C and Z purlins makes these machines versatile, suitable for various applications, from agricultural buildings to large commercial structures. This versatility allows manufacturers to meet diverse customer needs without investing in multiple machines.

Benefits of Implementing Quick Changeable Purlin Roll Forming Machines

The advantages of integrating quick changeable C/Z purlin roll forming machines into production lines are numerous

- Increased Productivity By minimizing downtime associated with tool changes, manufacturers can significantly increase overall productivity and throughput.

- Cost Savings With reduced labor costs and faster production times, companies can lower their operating expenses while still meeting high demand.

- Enhanced Flexibility The ability to produce different purlin types on demand allows manufacturers to respond quickly to market changes or specific project requests, providing a competitive edge.

- Improved Quality Control With automated settings and consistent production processes, the likelihood of defects and variances in product quality decreases, leading to higher customer satisfaction.

Conclusion

In conclusion, the quick changeable C/Z purlin roll forming machine is a game-changer in the construction industry. By offering increased speed, efficiency, and flexibility in production, it empowers manufacturers to meet the evolving demands of the market. As the construction landscape continues to modernize, embracing such technologies will be crucial for staying competitive. With the ongoing innovations in roll forming technology, the future looks bright for manufacturers ready to leverage these advancements for enhanced operational excellence.