Purlin stud track machines are revolutionizing the way construction projects are approached, offering unprecedented levels of efficiency and accuracy. As a professional in the construction industry, understanding the nuances of these machines and their impact on modern building techniques is crucial. This article delves into the expert functionalities of purlin stud track machines, providing insights that underscore their authority and trustworthiness in the field.

Crafted for precision and speed, purlin stud track machines are designed to produce high-quality metal studs and tracks for building frameworks. One of the key experiences shared by industry leaders is the remarkable reduction in time and labor consumption. Traditional methods of manually measuring, cutting, and assembling these components often lead to inconsistencies and material waste. However, with purlin stud track machines, there is a seamless integration of cutting-edge technology and automation that ensures exact measurements and cuts, thus reducing errors and optimizing resource usage.

Experts in the field emphasize the machine's adaptability, a feature that highlights its professional appeal. Customization is key in construction projects, and these machines excel by allowing operators to adjust settings for various sizes and specifications of studs and tracks. This customization capability is not only a testament to their advanced engineering but also a reflection of their responsiveness to tailored project requirements. The ability to produce different profiles and shapes without needing separate equipment reaffirms their authoritative presence in the market.

Authority in the construction equipment sector is often measured by innovative contributions, and purlin stud track machines are at the forefront. These machines utilize software integrations that accompany traditional mechanical processes, allowing for enhanced operational oversight. For instance, many machines come equipped with real-time data tracking and monitoring systems. These systems provide invaluable feedback on production rates and machine health, enabling proactive maintenance and operational adjustments. This technological sophistication fosters a level of trust between operators and their machinery, knowing that peak performance can be consistently maintained.

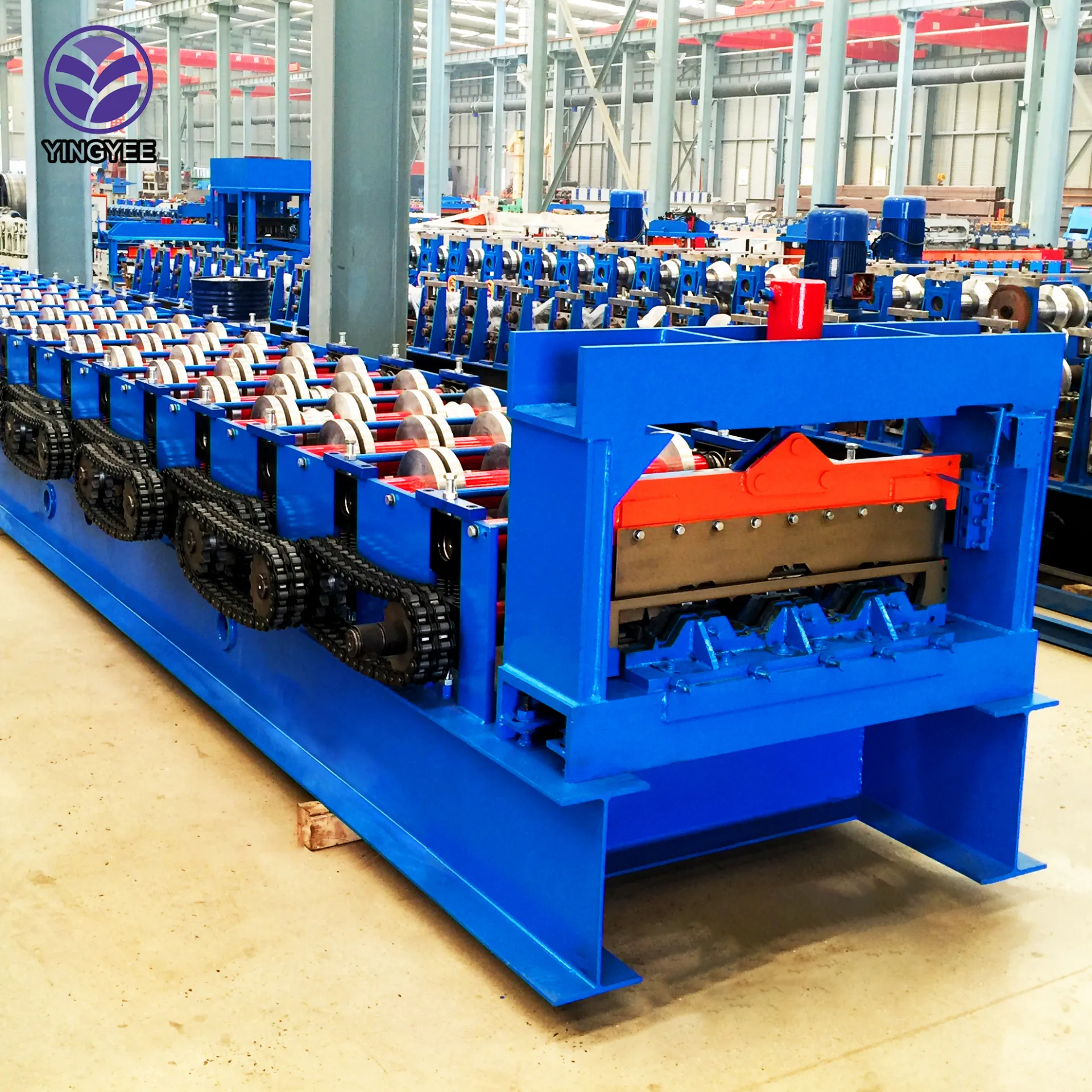

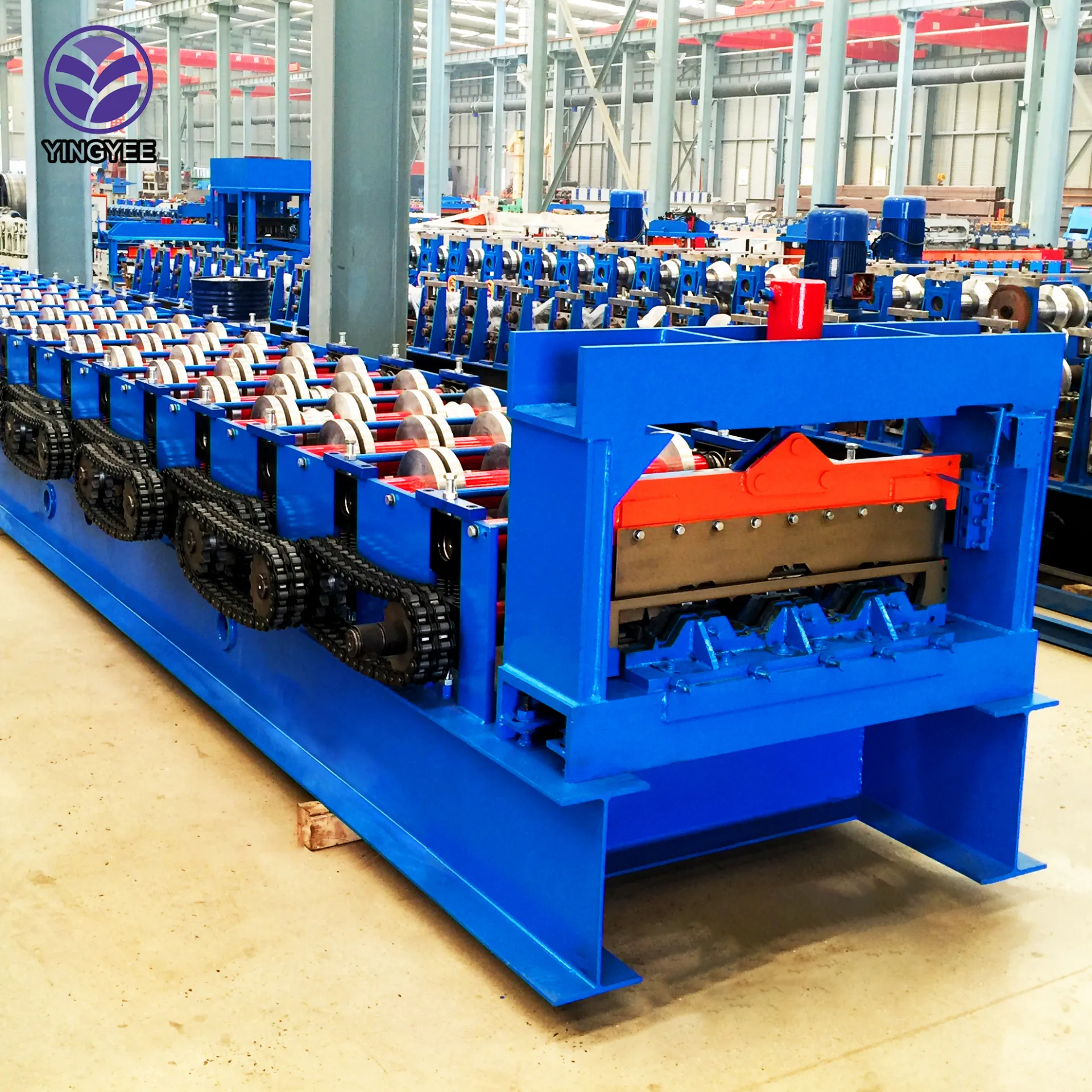

purlin stud track machine

Trustworthiness is further evidenced by the safety features embedded in modern purlin stud track machines. Construction sites prioritize safety, and these machines are designed with that principle in mind. They include automated shutdown protocols and safety barriers that significantly reduce the risk of on-site accidents. Moreover, comprehensive training programs offered by manufacturers ensure that operators are well-versed in machine handling and safety procedures, building confidence in both the machinery and its operators.

To reinforce their expertise, manufacturers of purlin stud track machines often engage in collaborative feedback loops with construction teams. This participatory approach not only aids in refining machine functionalities based on real-world usage but also establishes a symbiotic relationship fostering continual improvement and user satisfaction. Furthermore, these manufacturers often maintain a solid online presence, providing resources and customer support that reflect their commitment to quality and client trust.

The financial implications of investing in such advanced machinery are noteworthy. While the initial investment might appear substantial, the long-term benefits such as decreased labor costs, enhanced productivity, and reduced material waste contribute to a significant return on investment. Additionally, companies that integrate purlin stud track machines into their workflows often report higher client satisfaction due to the quality and consistency of the end product.

In conclusion, purlin stud track machines represent a paradigm shift in the construction industry. Their introduction combines engineering excellence with practical applications, offering unmatched reliability and efficiency. As construction demands evolve, these machines provide an inspiring glimpse into the future, where technology and construction merge seamlessly to foster productive and sustainable building practices. For industry professionals, investing in and mastering the use of these machines is not merely an option but a strategic necessity to remain competitive and authoritative in a rapidly advancing sector.