Navigating the complexities of industrial equipment, especially in the rapidly advancing sector of manufacturing machinery, requires a nuanced understanding of both technical specifications and practical applications. A significant component of modern warehousing and material handling solutions is the storage rack and beam roll forming machine. Delving into this machinery reveals vital insights that underscore its critical role in optimizing storage infrastructure.

The storage rack and beam roll forming machine stands as a paragon of precision engineering. Designed to transform raw steel into structurally robust storage racks, this machine addresses the industrial demand for durability and scalability. Storage racks produced from this machinery offer modular convenience, facilitating the dynamic inventory needs of warehouses globally.

In the realm of expertise,

understanding the operational mechanics of a roll forming machine is indispensable. Unlike traditional manufacturing processes, roll forming involves continuous bending of a long strip of metal, typically coiled steel, to produce the desired cross-section. This method is not only efficient but also reduces material waste, accentuating the machine's economic and environmental benefits. The precision of the forming process ensures that each beam and rack produced meets exacting standards, vital for safety and operational efficiency.

Authoritativeness in this domain is underscored by the machine's compliance with international industry standards. Trusted manufacturers subject their machines to rigorous testing, ensuring compliance with standards such as ISO 9001 for quality management systems. These certifications guarantee that the machine delivers on its promise of reliability and longevity, fostering confidence among industrial players.

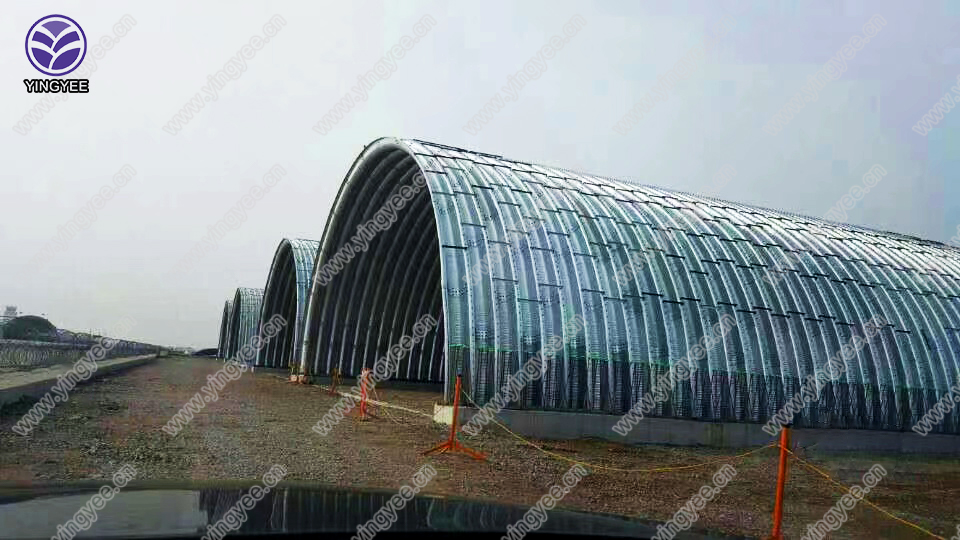

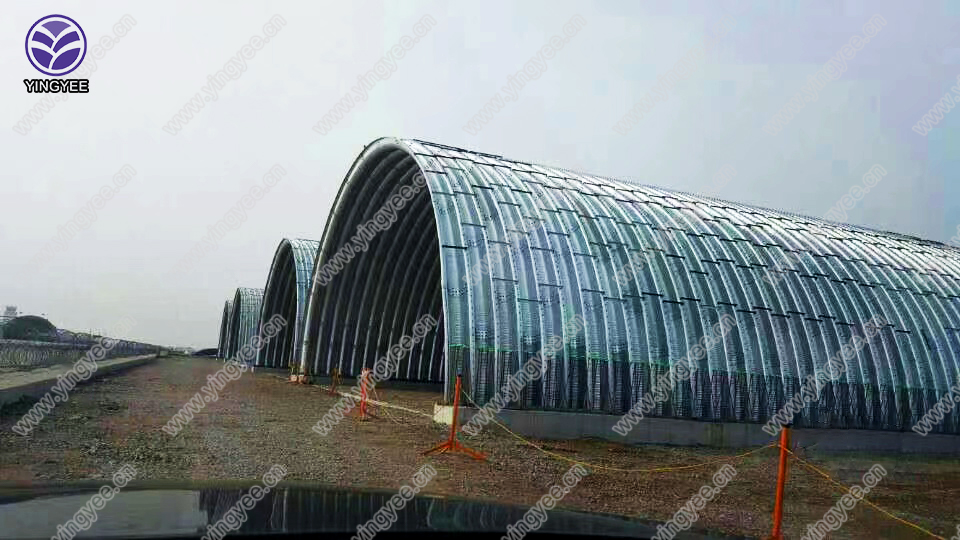

storage rack and beam roll forming machine

From an experiential perspective, the integration of a storage rack and beam roll forming machine in a manufacturing setting streamlines production workflows. Companies report significant time savings due to the machine's high-speed operations, capable of crafting racks at a pace that meets the swelling demands of modern logistics. Furthermore, the machine's automation reduces human error, a critical factor in maintaining consistency in storage rack quality.

Trustworthiness is further amplified by the machine's adaptability to various materials and specifications. Whether dealing with light-duty or heavy-duty storage needs, the roll forming machine can be customized to produce racks that match specific load-bearing requirements. Manufacturers who provide extensive support, including installation, training, and maintenance services, enhance this trust, ensuring that users can operate the machinery with minimal downtime.

Finally, the machine's contribution to sustainability cannot be understated. By reducing waste and enhancing the lifecycle of storage infrastructure, it aligns with the global shift towards more sustainable industrial practices. Venues equipped with high-quality storage solutions witness improved space utilization, ensuring that every square foot of a warehouse is optimized, thus driving cost efficiencies and boosting productivity.

Incorporating a storage rack and beam roll forming machine within an industrial setup signifies a strategic investment in the future of warehouse logistics. Its blend of efficiency, environmental consideration, and adaptability solidifies its place as an indispensable asset in modern manufacturing.