Purlin Stud Track Machine Revolutionizing Steel Profile Production

In the realm of manufacturing and construction, the demand for efficient, precise, and versatile machines has never been higher. Among these, the purlin stud track machine stands out as a pivotal innovation that enhances the production of steel profiles used in various applications, particularly in the construction industry.

The purlin stud track machine, often referred to simply as a stud track machine, automates the process of manufacturing steel tracks and purlins, which are essential components in framing systems, roofing, and wall structures. Traditionally, these components were crafted using labor-intensive methods that not only consumed time but also introduced significant margins for error. The introduction of automated purlin stud track machines has transformed this landscape, significantly improving productivity, reducing waste, and ensuring higher quality standards.

Key Features and Functionality

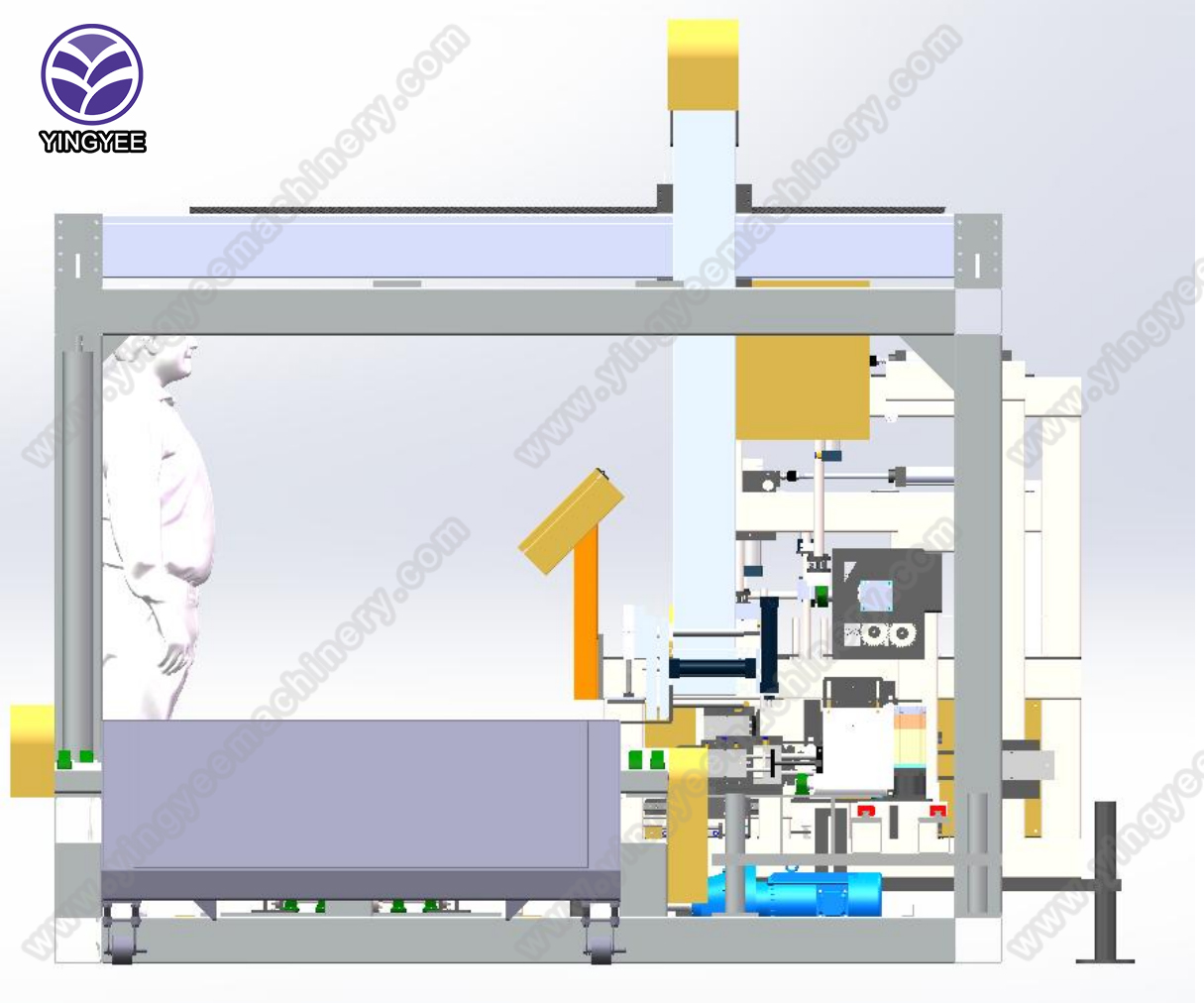

The modern purlin stud track machine boasts a variety of advanced features designed to optimize its performance

. One of the most significant benefits is its high-speed operation, capable of producing steel profiles at impressive rates without sacrificing quality. These machines utilize Computer Numerical Control (CNC) technology, which ensures precision in dimensions and enhances the repeatability of production.Another notable feature is the machine's adaptability. It can produce a wide range of profiles tailored to different specifications, catering to varying project requirements. The ability to adjust sizes and shapes quickly without needing extensive reconfiguration allows manufacturers to respond rapidly to changing market demands, a crucial advantage in the fast-paced construction sector.

Moreover, these machines often include integrated cutting and punching capabilities, streamlining the manufacturing process. By combining multiple operations within a single machine, manufacturers can reduce the need for additional equipment, thereby lowering investment costs and minimizing the physical footprint of production facilities.

Benefits of Purlin Stud Track Machines

The advantages of utilizing purlin stud track machines extend beyond mere efficiency. By automating the production process, companies can minimize labor costs. With reduced dependence on manual labor, the risk of workplace injuries is also significantly lowered, contributing to a safer working environment.

The precision offered by these machines leads to better quality control and reduces material waste. In the construction industry, where every piece of material counts, the ability to produce components that fit together flawlessly not only saves costs but also enhances the overall durability and integrity of structures.

Additionally, sustainable manufacturing practices are becoming increasingly important in today’s eco-conscious world. Purlin stud track machines can help companies meet sustainability goals by optimizing material usage and minimizing waste, as they can be programmed to produce only the required quantities with little excess, effectively reducing the carbon footprint associated with production.

Conclusion

The purlin stud track machine is a game-changer for the steel profile manufacturing industry. By marrying technology with manufacturing capabilities, it provides solutions that enhance efficiency, improve safety, and promote sustainability. As the construction industry continues to evolve, the role of the purlin stud track machine will likely grow, making it an indispensable tool for companies looking to thrive in a competitive market.

As we look toward the future, the ongoing advancements in automation and machine design promise even greater possibilities, ensuring that the purlin stud track machine will remain at the forefront of innovative manufacturing techniques, driving success and quality in every project undertaken. Thus, investing in such a machine is not merely an option; it is a strategic move towards staying relevant and competitive in a constantly changing industry.