Understanding the Purlin Stud Machine Revolutionizing Metal Framing

In the construction industry, efficiency and precision are paramount. The purlin stud machine is a cutting-edge tool that has transformed the way metal framing is done, particularly in building structures like warehouses, commercial buildings, and residential homes. This innovative equipment is designed to produce high-quality metal studs and purlins, streamlining the construction process and providing significant advantages over traditional methods.

What is a Purlin Stud Machine?

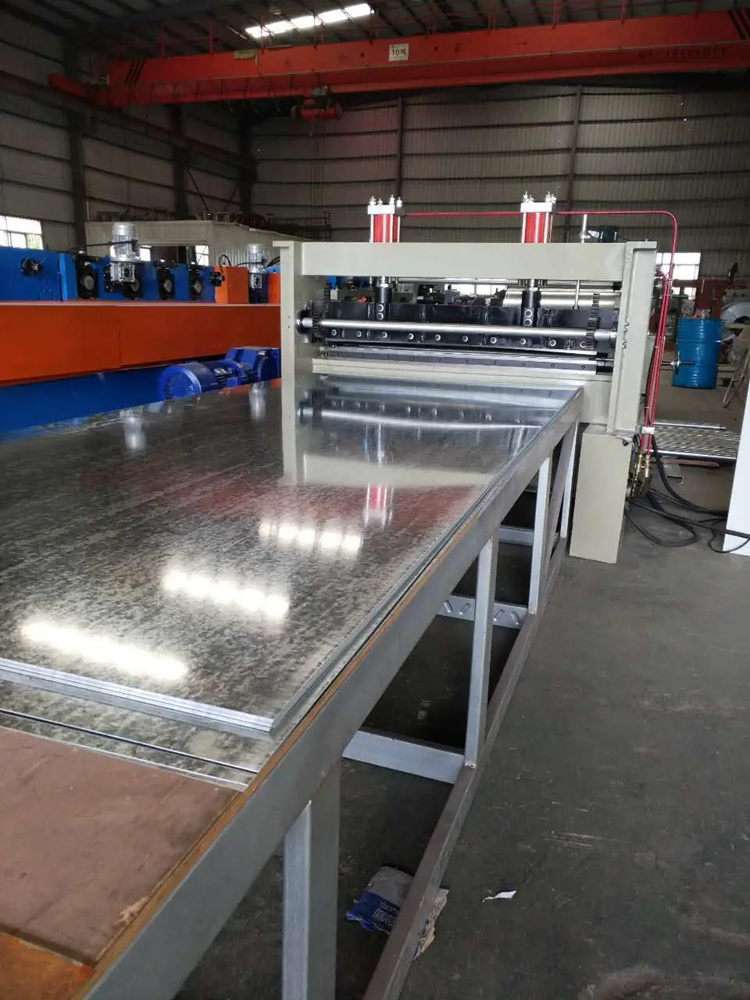

A purlin stud machine is an automated system that fabricates metal components, specifically purlins and studs, from coil steel. These components serve as the backbone of metal frame structures, providing critical support for roofs and walls. The machine combines various processes, including roll forming, cutting, and punching, into one seamless operation. This integration not only maximizes productivity but also ensures consistency in the quality of the finished products.

Key Features and Benefits

1. Precision Engineering One of the standout features of purlin stud machines is their ability to produce components with exceptional accuracy. Advanced computer numerical control (CNC) technology allows for precise adjustments, ensuring that the dimensions of the studs and purlins meet exact specifications. This precision reduces the need for additional adjustments on the job site, saving both time and labor costs.

2. Speed and Efficiency Traditional methods of framing often involve manual processes that can be time-consuming and labor-intensive. The purlin stud machine significantly speeds up production, capable of creating multiple profiles within a short timeframe. This rapid output is particularly beneficial for large-scale projects that require a high volume of framing materials.

3. Cost-Effectiveness While the initial investment in a purlin stud machine may seem substantial, the long-term financial benefits are undeniable. By reducing labor costs, minimizing waste, and accelerating project timelines, companies can achieve a higher return on investment. Additionally, the machine’s ability to operate with minimal supervision lowers ongoing operational expenses.

4. Versatility Modern purlin stud machines are designed to handle a variety of materials and profiles. Whether it’s creating C-sections, U-channels, or custom designs, these machines can be easily adjusted to accommodate different specifications. This versatility empowers contractors to undertake a wider range of projects without the need for multiple machines.

5. Enhanced Safety Automation in the construction process reduces the risk of workplace injuries associated with manual steel fabrication. With the purlin stud machine handling the heavy lifting and complex tasks, workers can focus on other aspects of construction, contributing to a safer work environment.

Applications in Construction

Purlin stud machines are primarily used in the prefabrication of metal framing systems, which are increasingly popular in various sectors. In commercial construction, these machines help produce the framework for office buildings, retail spaces, and warehouses, where durability and speed are critical. In residential architecture, they facilitate the construction of energy-efficient homes with lightweight materials, satisfying modern building codes and sustainability standards.

Conclusion

The purlin stud machine represents a significant advancement in the construction industry, providing contractors with the tools they need to enhance productivity, reduce costs, and improve safety. As the demand for faster and more efficient building methods continues to rise, this automated equipment is set to play an increasingly vital role in shaping the future of construction. Investing in a purlin stud machine not only streamlines operations but also positions companies at the forefront of modern building practices, ready to meet the challenges of the evolving industry. The integration of technology in construction is here to stay, and the purlin stud machine is leading the way.