The Evolution of Purlin Stud Machines Revolutionizing Steel Manufacturing

The manufacturing industry has witnessed significant advancements in technology over the years, particularly in the realm of steel construction. Among these innovations, the purlin stud machine has emerged as a crucial tool for fabricating purlins and studs used in various construction projects. This article will explore the significance, functionality, and advantages of purlin stud machines in the steel manufacturing sector.

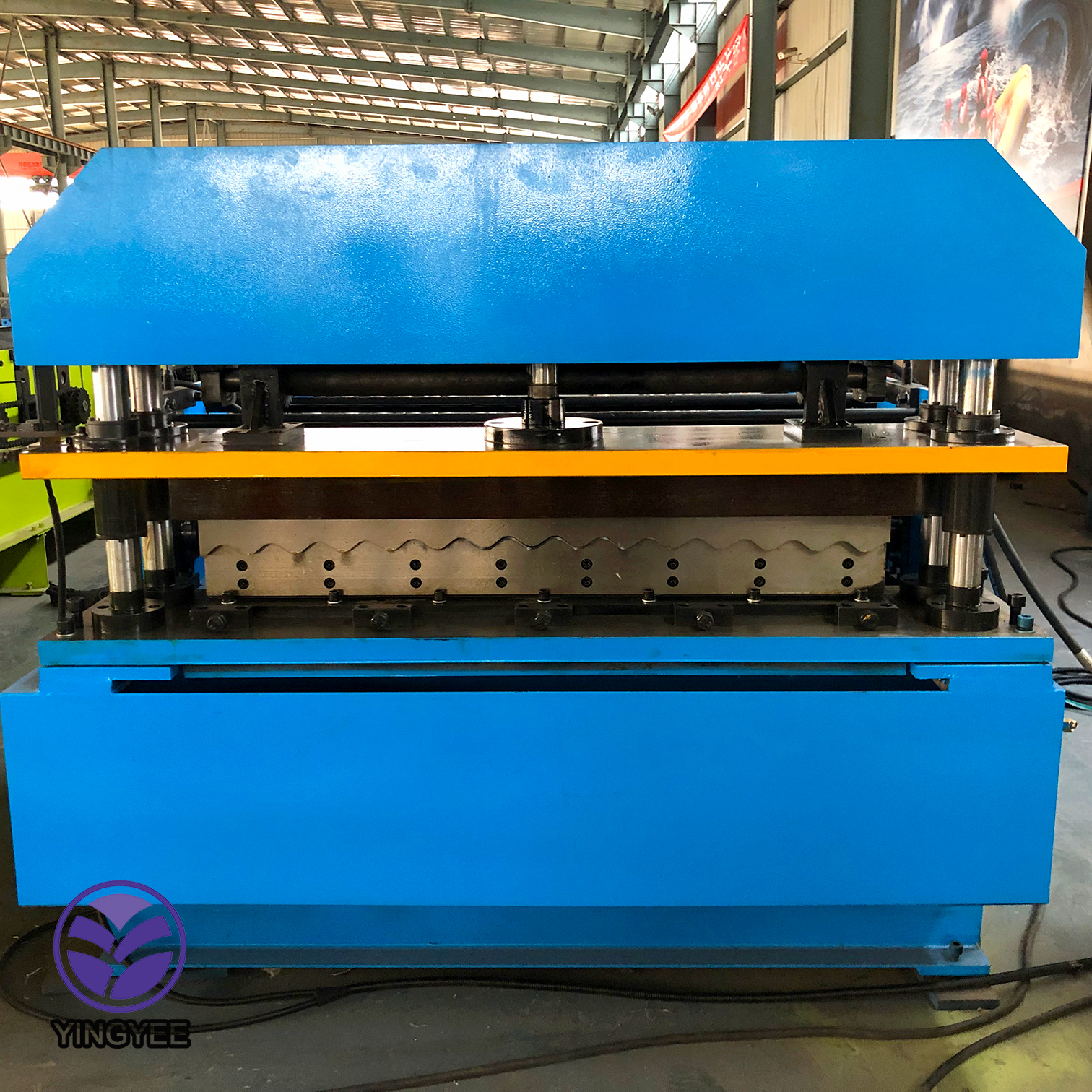

What is a Purlin Stud Machine?

A purlin stud machine is a specialized piece of equipment designed to produce purlins, which are horizontal beams used to support structures like roofs and walls in buildings. Typically made of steel, purlins are integral to creating stable frameworks in both commercial and residential constructions. The machine is also capable of producing studs—vertical components that form the framework of walls.

The process of purlin and stud manufacturing involves several stages, including cutting, bending, and forming. Modern purlin stud machines are automated and computer-controlled, allowing for precise measurements and repeatable quality in the manufacturing process. This precision is essential, as it ensures that the purlins and studs meet the exact specifications required for different construction applications.

Key Features and Functionality

Purlin stud machines come equipped with various features that enhance their functionality. For instance, many modern machines utilize high-speed roll forming technology. This process involves feeding flat steel sheets through a series of rollers that sequentially shape the material into the desired profile while maintaining high speed and accuracy. The result is uniform purlins and studs that can be produced in large quantities without compromising quality.

Additionally, these machines often include advanced control systems with user-friendly interfaces that allow operators to adjust dimensions and parameters as needed swiftly. The ability to manufacture custom sizes and profiles on-demand can significantly reduce lead times for construction projects, leading to increased efficiency.

Another notable feature of purlin stud machines is their adaptability. Many models can accommodate various types of steel, including galvanized and high-strength materials. This flexibility makes them suitable for different construction requirements and enhances their appeal to manufacturers in the steel industry.

Advantages of Purlin Stud Machines

The adoption of purlin stud machines brings numerous advantages to the steel manufacturing process. One of the primary benefits is the reduction of labor costs. Automation and streamlined production processes minimize the need for extensive manual labor, enabling manufacturers to redirect their workforce towards other areas of the business.

Moreover, these machines contribute to waste reduction. Traditionally, steel fabrication can produce significant scrap material due to manual cutting and shaping. However, automated purlin stud machines are designed to maximize material usage, ensuring that a greater percentage of the steel is transformed into usable products.

Another advantage is the enhancement of safety in the workplace. Automated machines reduce the likelihood of accidents that can occur during manual fabrication processes. By significantly lowering human intervention during production, companies can create a safer working environment, leading to fewer injuries and associated costs.

Conclusion

In summary, the advent of purlin stud machines has transformed the landscape of steel manufacturing, offering innovative solutions that enhance efficiency, accuracy, and safety. As construction demands continue to grow, the role of these machines will likely expand, cementing their place in the future of the steel industry. Manufacturers that embrace this technology can expect to gain competitive advantages in terms of production capabilities, cost efficiency, and overall quality, ultimately contributing to the success of their construction projects. The purlin stud machine represents not just a tool, but a significant leap forward in the evolution of steel fabrication practices.