The Efficiency of Purlin Stud Machines in Modern Construction

In the realm of modern construction, efficiency and precision are paramount. One of the key innovations that have significantly enhanced the productivity of the construction industry is the purlin stud machine. This specialized equipment is designed to streamline the process of creating purlins and studs, which are essential components in steel framing.

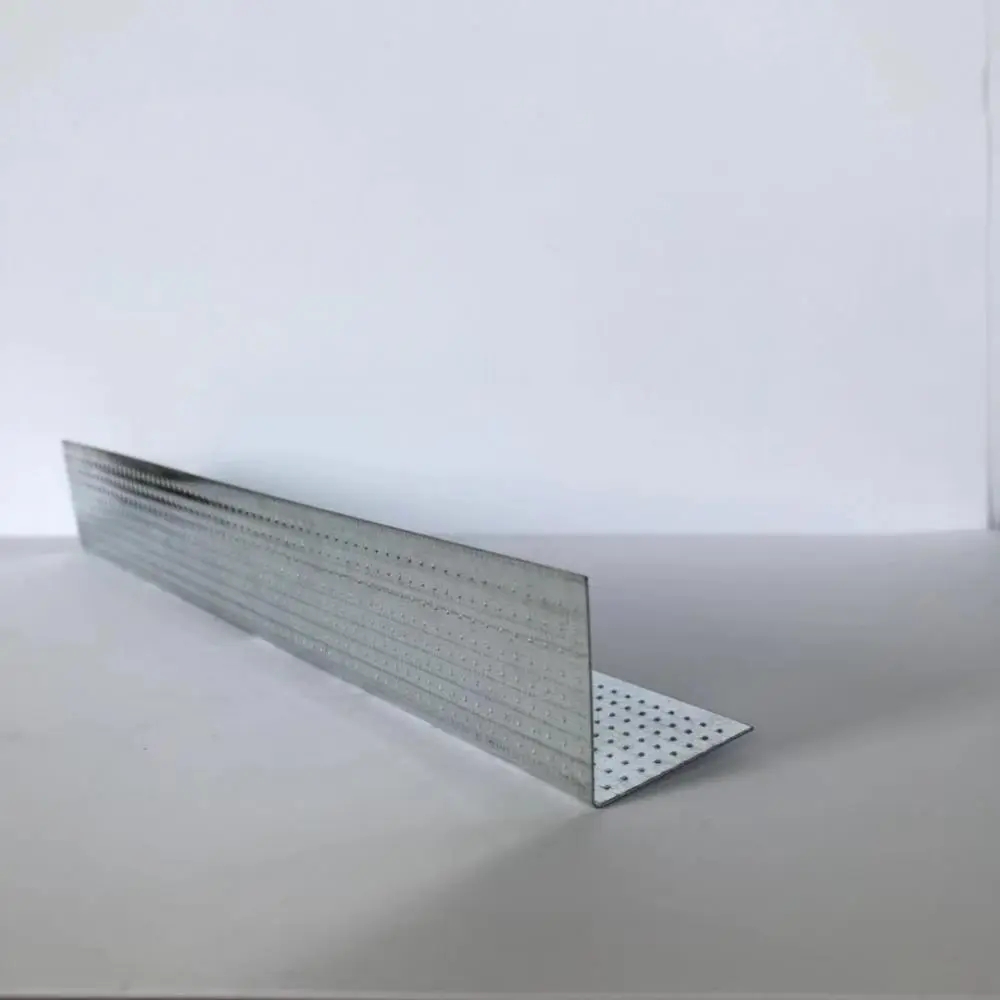

Purlins serve as horizontal support beams that help to distribute the load of the roof or wall system, while studs are vertical members that support the framework of a building. Traditionally, fabricating these components involved manual labor and basic tools, which were not only time-consuming but also prone to errors. However, the advent of the purlin stud machine has revolutionized this aspect of construction.

These machines are equipped with advanced technology that enables high-speed production of purlins and studs with exceptional accuracy. By utilizing computer numerical control (CNC) systems, operators can input precise measurements and designs, ensuring that each component meets the specific requirements of a project. This level of customization is invaluable for construction projects that demand unique structural designs or dimensions.

Moreover, the purlin stud machine offers significant time savings. With automated processes, the machine can produce multiple components in a fraction of the time it would take to do so manually. This increase in production speed not only accelerates project timelines but also reduces labor costs, making it a financially viable option for contractors.

In addition to efficiency and cost-effectiveness, these machines contribute to sustainability in construction. By minimizing waste through precise cutting and shaping, purlin stud machines ensure that materials are used judiciously, reducing the overall environmental impact of a project. This eco-friendly approach aligns with the growing emphasis on sustainable building practices.

Furthermore, the versatility of purlin stud machines allows them to be used in various applications, from residential buildings to large commercial structures. Their ability to adapt to different materials—such as steel and aluminum—further enhances their appeal within the industry.

In conclusion, the introduction of purlin stud machines marks a significant advancement in construction technology. By combining speed, precision, and sustainability, these machines have transformed the way purlins and studs are fabricated. As the demand for innovative building solutions continues to grow, the purlin stud machine will undoubtedly play a pivotal role in shaping the future of construction.