The Versatility and Advantages of Prepainted Galvanized Steel Coil

Prepainted galvanized steel coil (PPGI) is a remarkable material that has revolutionized various industries due to its impressive combination of durability, aesthetic appeal, and versatility. This article provides insights into what PPGI is, its manufacturing process, applications, and the numerous benefits it offers.

What is Prepainted Galvanized Steel Coil?

PPGI refers to steel sheets that have been coated with a layer of zinc to prevent corrosion and subsequently painted before being rolled into coils. This process provides a smooth, uniform surface that enhances the steel’s properties while also giving it an appealing finish. The base steel is coated with a layer of zinc using either hot-dip galvanizing or electro-galvanizing methods. The prepainting is then performed using advanced techniques that ensure an even coat of paint, available in a multitude of colors and finishes.

Manufacturing Process

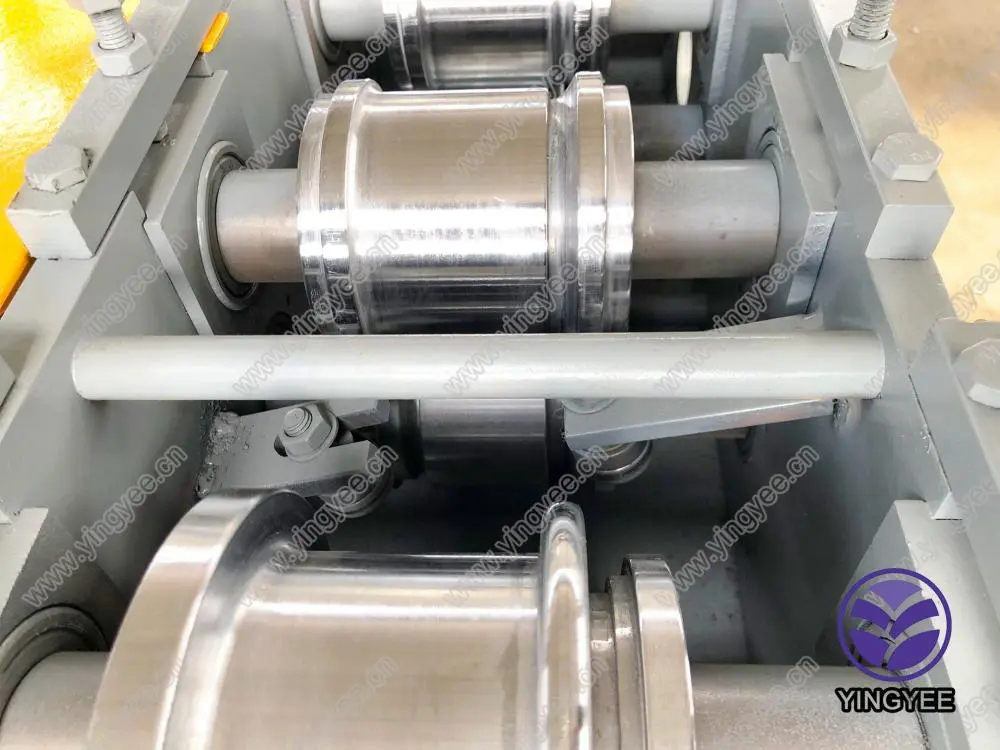

The manufacturing of prepainted galvanized steel begins with the selection of high-quality cold-rolled steel as the substrate. The steel undergoes a cleaning process to remove any contaminants. This is followed by the galvanization process, where it is immersed in molten zinc or subjected to an electroplating method to create a protective zinc layer. After the galvanization, the steel is then pre-painted using methods such as roller coating or spray coating.

After the painting process, the finished coils are cured in an oven, ensuring the adhesion of the paint to the zinc layer. This final step contributes significantly to the material's longevity and resilience, allowing it to withstand harsh climates and environmental conditions.

Applications of PPGI

The versatility of prepainted galvanized steel coil makes it suitable for various applications across different industries. Some of the most common uses include

1. Construction PPGI is extensively used in the construction of residential and commercial buildings. It is ideal for roofing sheets, wall cladding, and decorative facades due to its lightweight properties and available variety of finishes.

2. Automotive Industry The automotive sector employs PPGI for parts manufacturing, offering corrosion resistance, aesthetic versatility, and high strength.

3. Home Appliances Many large and small appliances, such as refrigerators, washing machines, and air conditioners, often use PPGI for their exterior panels, blending durability with design.

Benefits of Prepainted Galvanized Steel Coil

PPGI boasts several advantages that make it an attractive choice for manufacturers and builders alike

- Corrosion Resistance The zinc coating provides excellent protection against rust, ensuring that the underlying steel remains intact for an extended period, even in adverse weather conditions. This longevity translates into lower maintenance costs.

- Aesthetic Variety Available in a wide range of colors and finishes, PPGI can cater to various aesthetic preferences, allowing designers the freedom to create visually appealing structures and products.

- Ease of Fabrication PPGI is easy to work with and can be easily cut, shaped, and formed into various styles and dimensions, making it a preferred choice for manufacturers.

- Sustainability Many PPGI products can be recycled, making them an environmentally friendly option. The production process can also be optimized to reduce waste, aligning with the growing trend of sustainability in manufacturing.

- Cost-Effectiveness While PPGI is an investment, its durability and low maintenance requirements lead to cost savings in the long run, appealing to both manufacturers and consumers.

Conclusion

In conclusion, prepainted galvanized steel coil offers a unique combination of durability, aesthetic appeal, and versatility, making it an invaluable material across various industries. As technology advances and the demand for sustainable building materials continues to rise, PPGI is well-positioned to remain a popular choice among manufacturers and builders alike. Its multitude of applications and benefits solidifies its status as a go-to material in modern construction and manufacturing processes. Ultimately, PPGI not only meets functional requirements but also enhances the visual appeal of products, contributing to the overall quality and longevity of structures and items made from it.