The Benefits of Portable Standing Seam Roll Formers

In the rapidly evolving construction industry, efficiency and adaptability are essential. One tool that has become increasingly popular among contractors and builders is the portable standing seam roll former. This innovative equipment revolutionizes the way metal roofing systems are created, offering numerous advantages for both on-site fabrication and overall project management.

What is a Portable Standing Seam Roll Former?

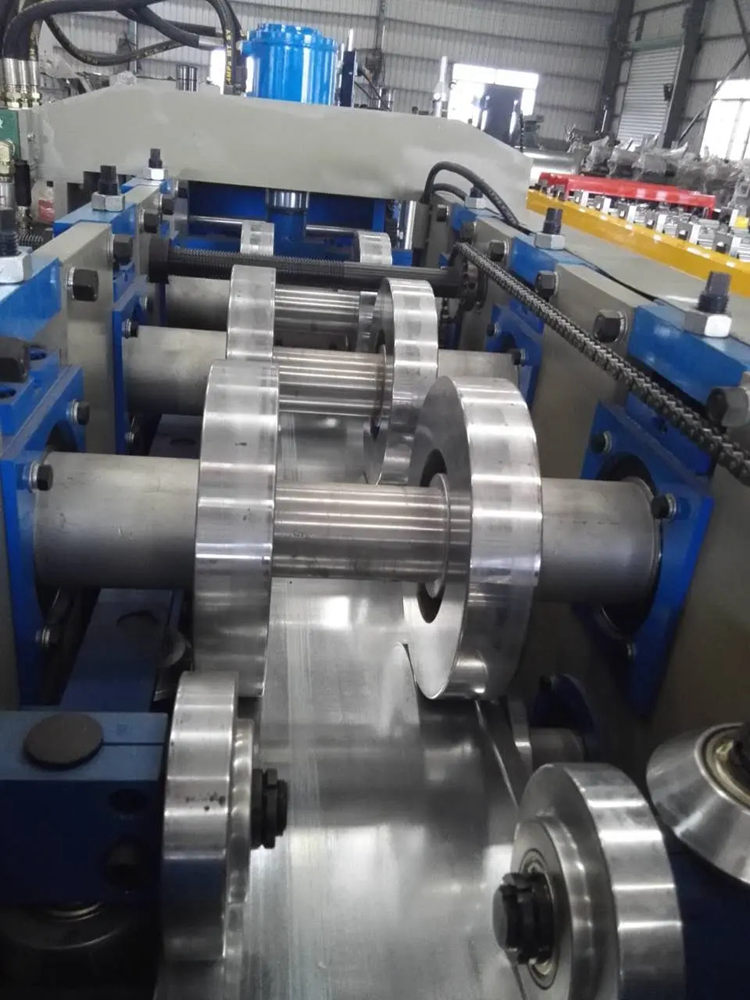

A portable standing seam roll former is a machine used to fabricate metal roofing panels in a standing seam design, directly at the job site. This system allows for the production of continuous sheets of metal roofing, tailored to meet the specific dimensions of a roof, without the need for excessive material waste or complicated shipping logistics. Typically powered by electricity or batteries, these machines can be easily transported and set up, making them ideal for a variety of construction projects, from residential homes to commercial buildings.

Advantages of Using Portable Standing Seam Roll Formers

1. Customization One of the most significant advantages of using portable standing seam roll formers is the ability to create custom lengths and profiles for roofing panels. Because the machine can produce panels on-site, contractors can easily adapt to unique architectural designs or alterations during the construction process, thus eliminating the need for pre-ordered materials that may not fit or look right.

2. Reduced Waste Traditional metal roofing manufacturing often leads to excess material due to standard preset lengths. In contrast, roll formers create panels to the precise length needed for the project, which significantly reduces waste and ultimately contributes to a more environmentally friendly approach. This aspect not only minimizes costs associated with material waste but also supports sustainable building practices.

3. Enhanced Efficiency Using a portable standing seam roll former can accelerate the roofing installation process. By producing the panels on-site, contractors minimize the amount of time spent waiting for deliveries or dealing with logistics. This efficiency can lead to quicker project completion times, which in turn increases productivity and profitability for contractors.

4. Durability and Quality Standing seam roofs are known for their durability and resistance to weather extremes. The roll forming process, especially when done on-site, allows for a high degree of quality control, as contractors can monitor the integrity of the panels during production. This attention to quality ensures that the final roofing product will be robust, requiring less maintenance over time.

5. Cost-Effective Solutions Although the initial investment in a portable standing seam roll former may appear significant, the long-term savings in materials, labor, and time pay dividends. Contractors can cut installation costs and improve their bidding competitiveness, particularly in markets where efficiency and customization are highly valued.

6. Ease of Use and Mobility Portable standing seam roll formers are designed for convenience. Their lightweight and compact design allows for easy transport between job sites, and many models come equipped with user-friendly controls, enabling quick operation even for those with limited experience in metal fabrication.

Conclusion

In conclusion, portable standing seam roll formers represent a game-changing tool in the construction and roofing industry. Their ability to customize, reduce waste, enhance efficiency, and provide quality roofing solutions makes them an invaluable asset for contractors. As the demand for high-performance, sustainable building materials grows, embracing this technology will not only help streamline operations but also deliver superior results to clients. By investing in portable standing seam roll formers, builders can position themselves at the forefront of the industry, ready to meet the challenges of modern construction with confidence.