Understanding Portable Standing Seam Roll Formers

In the realm of modern construction and roofing, efficiency and precision are paramount. One of the innovations that have significantly contributed to these aspects is the portable standing seam roll former. This machinery has transformed the way contractors approach metal roofing, enabling them to fabricate panels on-site, thereby reducing waste, transportation costs, and labor hours.

What is a Portable Standing Seam Roll Former?

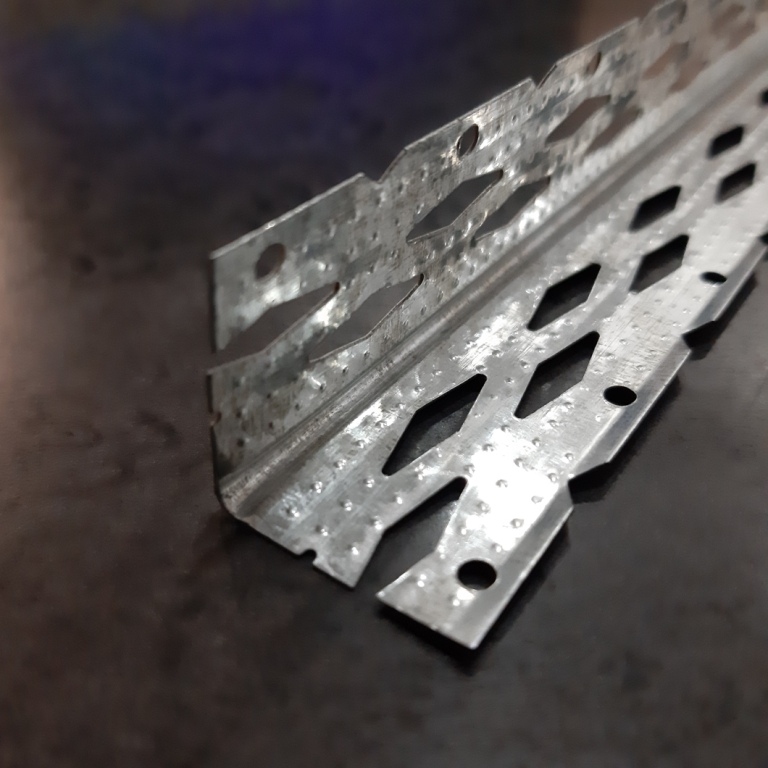

A portable standing seam roll former is a specialized piece of equipment designed to create standing seam metal roofing panels. Unlike traditional roofing methods that often use shingles or other types of roofing materials, standing seam roofs are characterized by their vertical seams that interlock, providing a sleek, modern aesthetic while effectively channeling water off the roof.

The roll former operates by feeding coiled metal sheets, typically made of aluminum or steel, through a series of rollers that shape the metal into the desired profile and cut it to length. The portability aspect of these machines allows them to be transported to various job sites, making them ideal for projects of different scales—from residential homes to large commercial buildings.

Advantages of Portable Standing Seam Roll Formers

1. Cost Efficiency Fabricating panels on-site eliminates the need for transporting pre-fabricated panels, which can be bulky and expensive. This not only reduces shipping costs but also minimizes the risk of damage during transportation.

2. Customization Each project has unique specifications in terms of design, length, and width. A portable roll former allows contractors to customize each panel on-site, ensuring that the product fits precisely with the project's requirements.

3. Reduced Waste By cutting panels to the exact dimensions needed, contractors can significantly reduce material waste. This not only saves money but also adheres to sustainable construction practices.

4. Ease of Use Modern portable standing seam roll formers are designed with user-friendly controls and features that make them accessible for operators with varying levels of expertise. This ease of operation contributes to a faster turnaround time for projects.

5. Durability and Performance Standing seam roofs are known for their longevity and robust performance against harsh weather conditions. Using a roll former to create these roofs on-site enhances the integrity of the panels, as they are manufactured without unnecessary joints or seams.

Applications of Portable Standing Seam Roll Formers

Portable standing seam roll formers find their primary application in roofing, where they are used to create panels for commercial buildings, residential homes, warehouses, and industrial facilities. Beyond roofing, they can also be employed to manufacture metal siding and wall panels, offering a consistent look and feel.

Contractors who invest in this machinery can take on a wider range of projects, as the ability to produce standing seam panels on-demand expands service offerings. This versatility can lead to increased market opportunities and improved customer satisfaction.

Choosing the Right Portable Standing Seam Roll Former

When selecting a portable standing seam roll former, there are several key considerations to keep in mind

- Capacity Evaluate the machine's ability to handle different metal thicknesses and materials. A versatile machine can accommodate a wider range of projects. - Portability Consider the weight and dimensions of the roll former. It should be easy to transport without sacrificing performance. - Speed Look for equipment that offers high production speeds to maximize efficiency on job sites. - Technical Support Opt for manufacturers that provide robust customer service and support, as this can be crucial for maintenance and troubleshooting.

Conclusion

The introduction of portable standing seam roll formers has revolutionized the roofing industry, providing contractors with tools that enhance efficiency, reduce costs, and improve customization. With numerous advantages and applications, investing in this equipment can significantly benefit businesses looking to expand their service offerings and improve operational efficiency. As the construction industry continues to evolve, the demand for such innovative solutions will undoubtedly grow, making portable standing seam roll formers an essential asset for any contractor involved in metal roofing.