Understanding Portable Standing Seam Roll Formers

The construction industry has seen significant advancements in technology, leading to more efficient and sustainable building practices. One innovation that stands out is the portable standing seam roll former. This powerful tool revolutionizes the way metal roofing is manufactured and installed, providing unmatched flexibility, quality, and efficiency.

What is a Portable Standing Seam Roll Former?

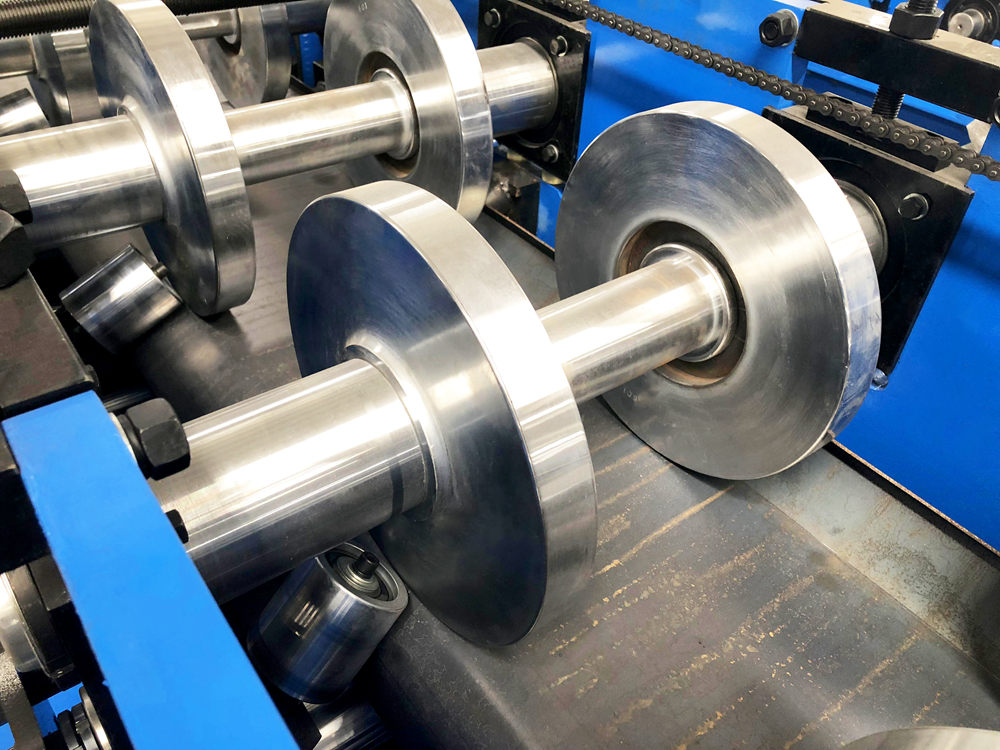

A portable standing seam roll former is a machine designed to create standing seam metal roofing panels on-site. Unlike traditional roofing methods that often require pre-manufactured materials shipped from a factory, portable roll formers allow contractors to produce the required panels at the job site. This not only reduces transportation costs but also minimizes waste and environmental impact.

The standing seam system features raised interlocking seams that ensure tighter seals against water infiltration, making it a preferred choice for both commercial and residential applications. The precision engineered profiles produced by roll formers provide superior durability and aesthetics compared to other roofing options.

Benefits of Portable Roll Forming

1. Flexibility and Efficiency One of the standout features of portable standing seam roll formers is their adaptability. These machines can easily be transported to various job sites, allowing for quick adaptation to different project requirements. Contractors can produce panels in various lengths to match the specific dimensions of a roof, reducing the need for excess material and making it easier to address unexpected changes during installation.

2. Cost-Effectiveness By eliminating the need for shipping pre-formed panels, portable roll formers significantly reduce overall project costs. Homeowners and businesses benefit from lower material expenses and, in some cases, reduced labor costs, as fewer workers might be needed for handling and installation processes.

3. Quality and Precision The precision engineering of portable roll formers ensures that each panel produced has uniform dimensions and quality. This level of consistency is crucial for achieving a professional appearance and ensuring the structural integrity of the roof. Additionally, many modern roll formers come equipped with advanced features, such as computerized controls, which enhance the accuracy of the panel profiles.

4. Reduced Waste Traditional roofing methods often generate significant amounts of waste due to cutting and fitting pre-manufactured materials. With portable roll formers, panels are made to specification on-site, significantly minimizing scrap material and contributing to more environmentally responsible building practices.

Conclusion

The portable standing seam roll former represents a significant advancement in roofing technology, offering numerous benefits for builders and property owners alike. As the construction industry continues to evolve, the adoption of portable roll forming solutions is likely to increase, driven by the demand for efficiency, sustainability, and quality.

Contractors who invest in this technology can enhance their service offerings, meet client demands for high-quality roofing solutions, and streamline their operations. As the market for metal roofing continues to grow, the role of portable standing seam roll formers will become increasingly crucial in delivering innovative and effective roofing solutions that stand the test of time. With advancements in engineering and manufacturing processes, portable roll formers are not just a trend; they represent the future of efficient and quality-driven construction in the metal roofing sector.