Certainly! Here's a 436-word article on the topic of PLC Adjust Size C Z Purlin Machine.

---

PLC Adjust Size C Z Purlin Machine Revolutionizing Steel Fabrication

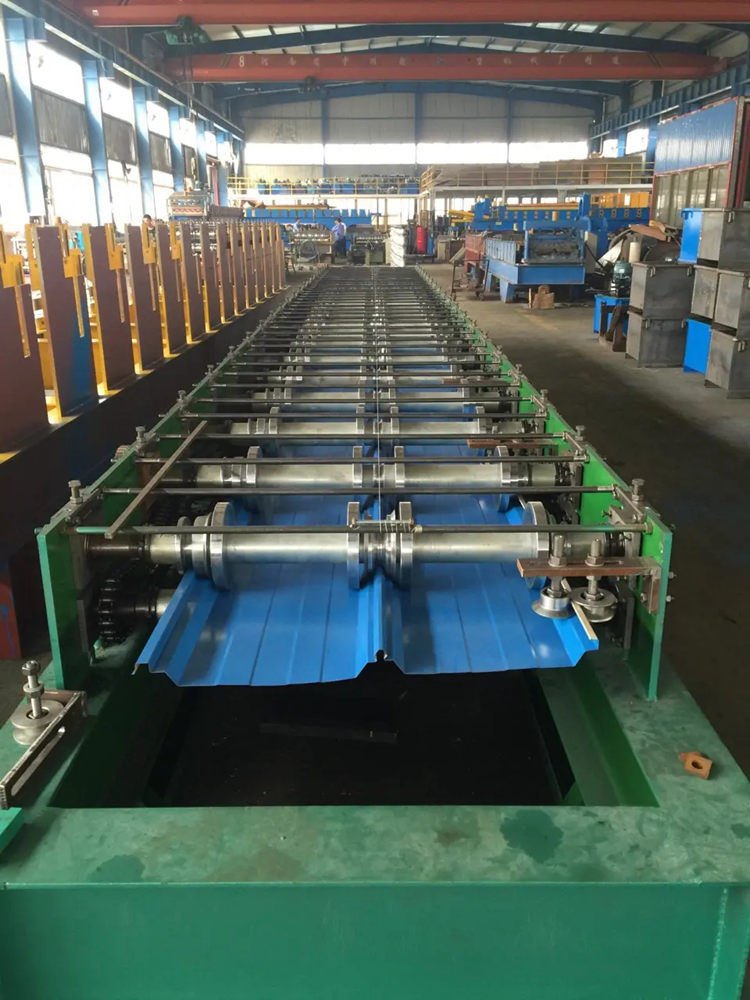

In the ever-evolving field of steel fabrication, the PLC Adjust Size C Z Purlin Machine stands out as a significant advancement. This innovative machine integrates precision engineering and programmable logic control (PLC) technology to enhance efficiency and adaptability in producing C and Z purlins, which are essential components in construction and structural engineering.

Traditionally, the manufacturing of purlins involved manual adjustments and cumbersome processes. This not only limited the production capacity but also increased the chances of errors. However, the PLC Adjust Size C Z Purlin Machine revolutionizes this process by allowing operators to easily modify dimensions and specifications through a user-friendly interface. By utilizing PLC technology, this machine can automatically adjust to different sizes of purlins with minimal downtime, thus significantly improving productivity.

One of the standout features of the PLC Adjust Size C Z Purlin Machine is its ability to handle various materials with ease. Whether it is galvanized steel or other types of metal, the machine can process materials quickly and efficiently. This versatility enables manufacturers to cater to a wide range of industry needs, from residential construction to large-scale commercial projects.

Moreover, the precision of the PLC system ensures that every purlin produced meets strict quality standards. The ability to monitor and adjust the production parameters in real-time helps in reducing waste and optimizing resource utilization. This is not only beneficial for the environment but also translates into cost savings for manufacturers.

Safety is another aspect where the PLC Adjust Size C Z Purlin Machine excels. Equipped with advanced safety features and emergency stop mechanisms, this machine minimizes the risk of accidents in the workplace. Operators can work with confidence, knowing that their safety is prioritized, which is crucial in a sector known for its demanding requirements.

The growing demand for customized purlins has also been a driving force behind the adoption of this technology. As construction projects become more intricate, the need for tailored solutions has surged. The flexibility offered by the PLC Adjust Size C Z Purlin Machine empowers manufacturers to produce purlins of different lengths, thicknesses, and shapes in response to client specifications, enhancing customer satisfaction.

In conclusion, the PLC Adjust Size C Z Purlin Machine is a game-changer in the steel fabrication industry. By embracing automation and precision, this machine not only streamlines the production process but also contributes to safer and more sustainable manufacturing practices. As the industry continues to evolve, such advancements will undoubtedly play a pivotal role in meeting the future demands of construction and structural engineering.

---

I hope this article meets your requirements!