The Evolution and Significance of Plate Shearing Machine Factories

In the realm of industrial manufacturing, the ability to cut metal sheets with precision and efficiency is essential. This is where plate shearing machines come into play. These machines are pivotal in various industries, including automotive, aerospace, construction, and more. The factory that specializes in the production and innovation of plate shearing machines is a nexus of mechanical engineering, technological advancement, and manufacturing prowess.

Understanding Plate Shearing Machines

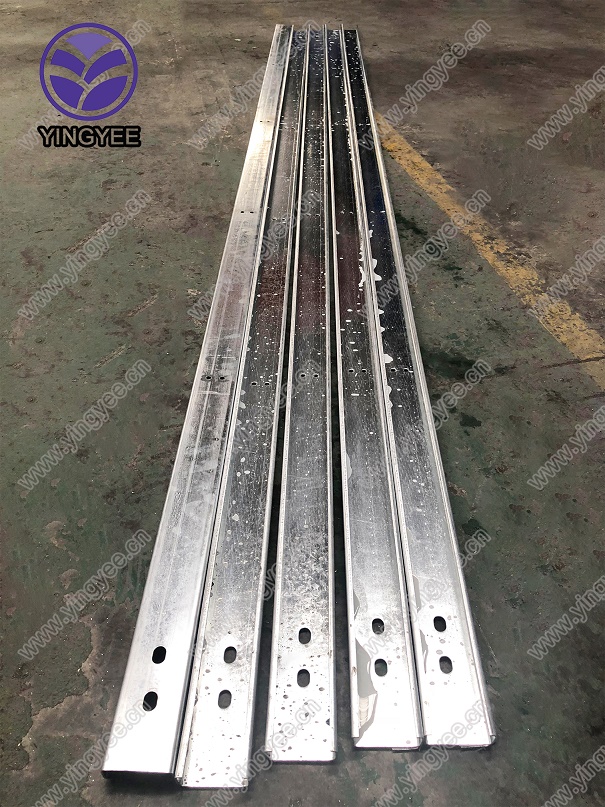

A plate shearing machine is designed to cut large sheets of metal into smaller sections with great accuracy. The process involves the application of shear force, resulting in the separation of the material along a straight line. This method of cutting is preferred over other techniques like sawing or milling due to its efficiency and the clean edges it produces.

The shearing process is fundamental in numerous applications. For instance, in the automotive industry, plates of metal must be sheared to specific dimensions to fit into the manufacturing of vehicles. Similarly, in construction, metal sheets need to be cut to size for structural components. Thus, the role of plate shearing machines cannot be overstated; they are the backbone of many manufacturing processes.

The Evolution of Shearing Technology

Plate shearing machines have evolved significantly over the years. Early models were manual, requiring considerable human effort and expertise. However, with the advent of technology, modern shearing machines are automated and equipped with state-of-the-art controls that enhance precision and reduce human error. The introduction of CNC (Computer Numerical Control) technology has revolutionized the shearing process. CNC plate shearing machines allow for intricate designs and exact cuts, which are programmed and executed with minimal manual intervention.

Moreover, advancements in hydraulic technology have also transformed shearing machines. Hydraulic shears provide greater force and effectiveness, enabling the cutting of thicker and harder materials. The combination of automation and hydraulic power has resulted in machines that can operate at higher speeds while maintaining accuracy, thus boosting productivity in factories.

The Role of Plate Shearing Machine Factories

Factories that produce plate shearing machines are integral to the manufacturing ecosystem. They engage in rigorous research and development to innovate and improve the shearing process continually. Engineers and designers work collaboratively to integrate the latest technology, ensuring that the machines produced are both efficient and user-friendly.

Quality control is another critical aspect of these factories. Each plate shearing machine goes through stringent testing to ensure that it meets the industry standards. The machines must operate flawlessly under various conditions and for extended periods, which requires an adherence to high manufacturing standards.

Additionally, these factories contribute to the economy by providing jobs and fostering skills in the engineering and manufacturing sectors. They often work closely with clients, offering customized solutions to meet specific industry requirements, thereby enhancing client satisfaction and retention.

Future Trends in Plate Shearing Machines

Looking forward, several trends are likely to shape the future of plate shearing machines and their factories. The integration of Industry 4.0 technologies, such as IoT (Internet of Things), promises to further optimize production processes. Machines equipped with sensors can provide real-time data on their performance, allowing for predictive maintenance and minimizing downtime.

Sustainability is also becoming a focal point in manufacturing. Factories are increasingly adopting eco-friendly practices, from energy-efficient machines to recycling materials. The demand for sustainable practices is pushing manufacturers to create shearing machines that consume less energy and can operate in an environmentally friendly manner.

Conclusion

The plate shearing machine factory is a vital part of the manufacturing landscape, facilitating the production of components that are crucial for various industries. As technology continues to advance, these factories will play an even more significant role in shaping the manufacturing processes of the future. In essence, they are not just manufacturers of machines; they are integral to the innovation and efficiency that drive modern industry. The future of plate shearing machines is promising, grounded in technology, quality, and sustainability, ensuring that they remain indispensable tools in the world of manufacturing.