Understanding the Plate Shearing Machine A Key Tool in Metal Fabrication

In the metal fabrication industry, the plate shearing machine stands out as a vital tool for cutting and shaping various types of metal sheets. This equipment is essential for manufacturers looking to create precise and clean cuts, which are crucial in the production of fabrication components used in a wide range of applications. This article delves into the functionality, types, and advantages of plate shearing machines, shedding light on their significance in modern manufacturing processes.

Functionality of Plate Shearing Machines

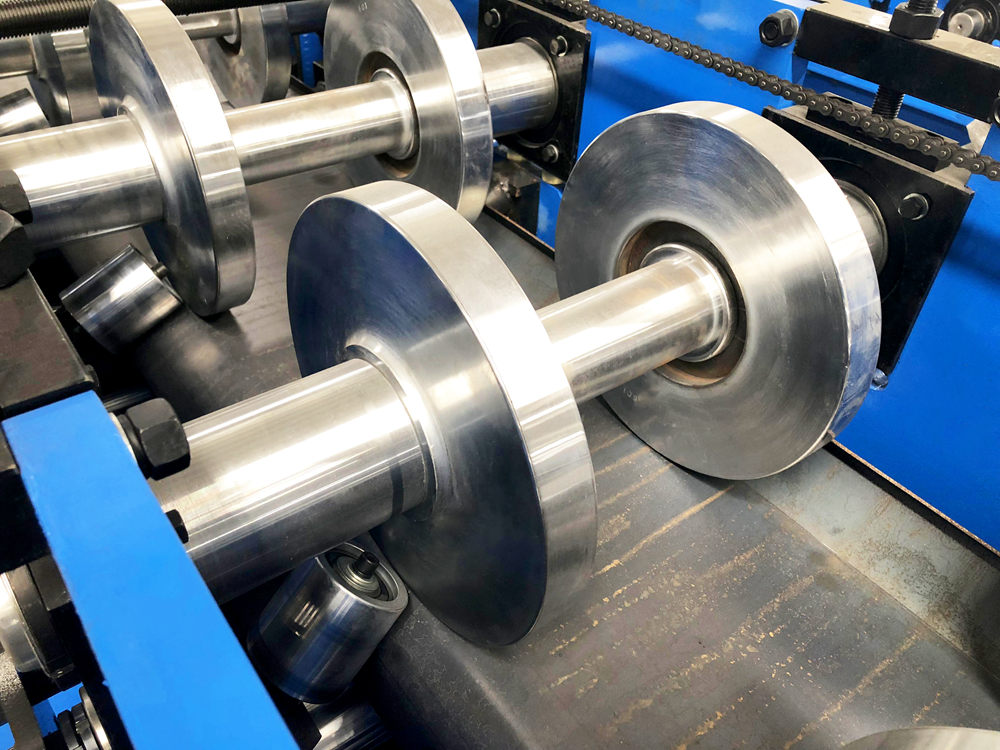

Plate shearing machines, also known as guillotine shears, utilize a straight blade to cut through various thicknesses of metal sheets. The fundamental operational mechanism involves the upper blade moving downwards in a linear motion, slicing through the material as it meets the fixed lower blade. This action not only ensures a clean cut but also minimizes material deformation. The level of precision and the degree of sharpness of the blades play a significant role in achieving the desired quality of cut.

The control systems of modern plate shearing machines have advanced significantly, enabling operators to set exact parameters for cutting angles, lengths, and thicknesses. This includes numerical control (CNC) systems that enhance automation and precision, allowing for complex cuts that would be challenging to achieve manually. Operators can input specific measurements, and the machine will automatically adjust its settings, reducing human error and increasing efficiency.

Types of Plate Shearing Machines

There are several types of plate shearing machines, each designed to accommodate different materials, thicknesses, and cutting techniques. Here are some of the most common types

1. Mechanical Shears These machines utilize a mechanical advantage through levers to generate the cutting force. They are generally used for lighter materials and offer a cost-effective solution for small-scale operations.

2. Hydraulic Shears Hydraulic plate shearing machines use hydraulic pressure to lift and lower the blade, providing significant cutting force and allowing them to handle thicker materials. They are favored in industries requiring heavy-duty operations due to their efficiency and capability.

3. Pneumatic Shears These machines operate using compressed air and are effective for lighter sheets. Their design allows for rapid cutting cycles and is ideal for applications that require speed over power.

4. CNC Shears With advancements in technology, CNC shears have become increasingly popular in industrial settings. These machines automate the cutting process, enabling high precision and repeatability—perfect for intricate designs and high-volume production runs.

Advantages of Plate Shearing Machines

The use of plate shearing machines offers numerous benefits for manufacturers

- Precision and Clean Cuts One of the most significant advantages of plate shearing machines is their ability to produce precise and clean cuts with minimal burrs. This reduces the need for additional finishing processes, saving both time and labor costs.

- Efficiency Automated systems and variable settings allow for rapid production cycles, contributing to increased overall efficiency in manufacturing workflows.

- Versatility These machines can cut various materials, including steel, aluminum, and other alloys, making them highly versatile tools in different manufacturing sectors.

- Cost-Effectiveness While the initial investment in a high-quality shearing machine may be substantial, the long-term savings from reduced material waste, faster production times, and lower labor costs make them a wise investment.

- Safety Features Modern plate shearing machines are equipped with several safety features, including protective guards and automatic shutdown functions, ensuring the safety of operators during operation.

Conclusion

The plate shearing machine is undeniably a cornerstone in the realm of metal fabrication. Its ability to deliver precision cuts, coupled with the efficiency and versatility it brings, makes it an indispensable tool for manufacturers. As industries continue to evolve, staying updated with the latest advancements in plate shearing technology will be crucial for businesses seeking to maintain a competitive edge. Embracing these machines not only enhances productivity but also ensures the high quality of fabricated products, underscoring their importance in contemporary manufacturing practices.