The Intricate Process of Pipes Making Machines

In the realm of modern manufacturing, the creation of pipes, whether for industrial purposes, plumbing, or construction, has been significantly revolutionized by technology. At the heart of this advancement lies the pipes making machine, a sophisticated tool designed to streamline production and enhance efficiency in creating various types of pipes. Understanding the functionality and benefits of these machines can shed light on their crucial role in modern industries.

How Pipes Making Machines Work

Pipes making machines operate using a combination of mechanical processes, which include wire drawing, forming, welding, and cutting. Initially, raw materials in the form of metal rods, plastic granules, or other feedstocks are prepared and processed. For metal pipes, the process often begins with wire drawing, where steel wire is pulled through a series of dies to reduce its diameter and increase its length.

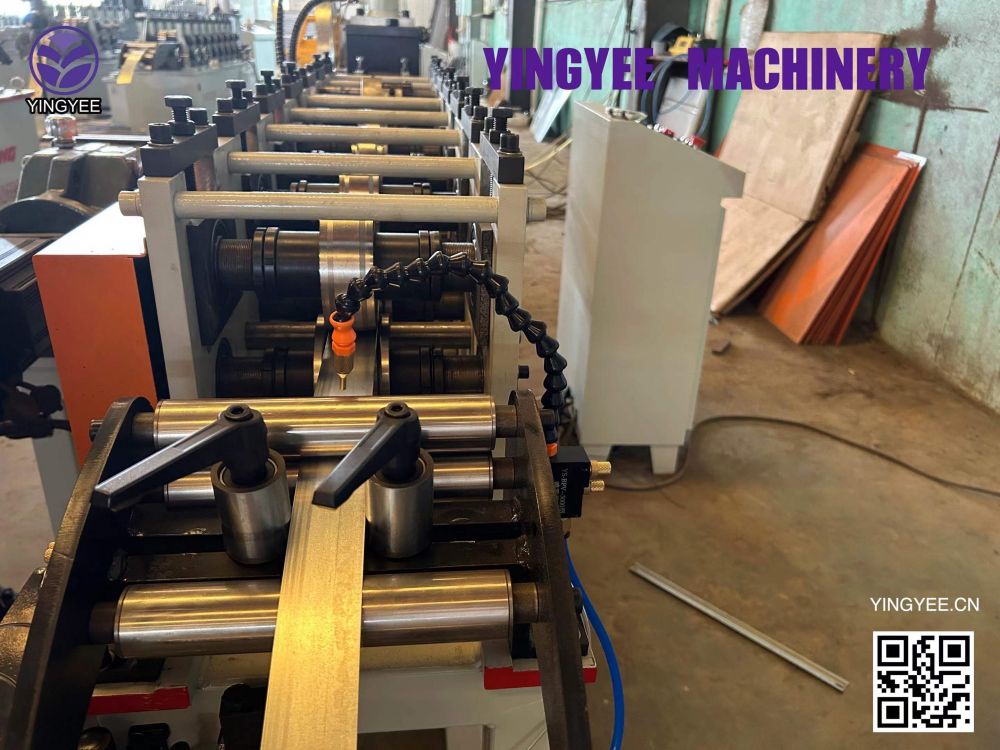

Once the desired diameter is achieved, the wire is fed into forming machines. These systems bend and shape the wire or sheet into the contours required for pipe production. Various techniques may be employed here, including roll forming, where a series of rollers gradually shape the material into a cylindrical form.

The welding stage is pivotal, particularly for metal pipes. Advanced machines use techniques such as Electric Resistance Welding (ERW) or Laser Welding to fuse the edges of the formed pipe together. This ensures a strong, durable product that can withstand the pressures encountered in everyday applications.

For plastic pipes, the process involves extrusion, where heated plastic is forced through a die to create continuous lengths of pipe. The flexibility of plastic enables the production of various pipe sizes and shapes, which can be cooled and cut to specific lengths as needed.

The Benefits of Pipes Making Machines

The introduction of pipes making machines has provided numerous advantages in the manufacturing landscape

. First and foremost, they significantly increase production speed. Traditional methods of pipe fabrication are often labor-intensive and time-consuming. With automated machines, industries can produce large quantities of pipes in a fraction of the time, enabling manufacturers to meet the growing demand for pipes across different sectors.Moreover, pipes making machines enhance precision. These machines are designed to produce uniformly sized pipes with consistent wall thickness, reducing waste and ensuring that the final products meet stringent quality standards. By minimizing human error, manufacturers can rely on these machines to deliver high-quality outputs every time.

Another significant advantage is the reduction in labor costs. Automated machines require fewer operators and less manual intervention, which can lead to cost savings. As maintenance and operational costs decline, manufacturers can allocate resources more effectively, investing in other areas of production or innovation.

The Future of Pipes Making Machines

As technology continues to advance, the future of pipes making machines looks promising. Innovations such as Industry 4.0 and the Internet of Things (IoT) are set to transform how these machines operate, enabling real-time monitoring and predictive maintenance. This can further enhance operational efficiency and reduce downtime, ensuring continuous production processes.

In addition, the focus on sustainability will likely drive the development of eco-friendly pipes making machines. Manufacturers may adopt biodegradable materials or energy-efficient technologies to minimize environmental impact, aligning with the global move towards greener manufacturing practices.

Conclusion

In conclusion, pipes making machines are a cornerstone of modern industrial production. Their ability to enhance speed, precision, and cost-effectiveness has made them invaluable across numerous industries. As technology continues to evolve, these machines will undoubtedly adapt, paving the way for even more efficient and sustainable manufacturing processes. The future is bright for pipe production, thanks in large part to the capabilities and innovations within pipes making machines.