The Evolution and Importance of Pipes Making Machines

In the ever-evolving landscape of manufacturing, the production of pipes has become a critical component across various industries. From construction and plumbing to oil and gas, the demand for high-quality pipes is incessantly increasing. At the heart of this demand lies the pipes making machine, an innovative technology that has revolutionized the way pipes are manufactured. This article delves into the evolution, technology, and importance of pipes making machines in modern manufacturing.

The Evolution of Pipes Making Machines

The manufacturing of pipes dates back centuries, with early artisans using rudimentary tools to create simple pipes for water transport. However, as industrialization took hold in the 19th century, the need for more efficient and standardized manufacturing processes emerged. The introduction of pipes making machines marked a significant turning point in this evolution.

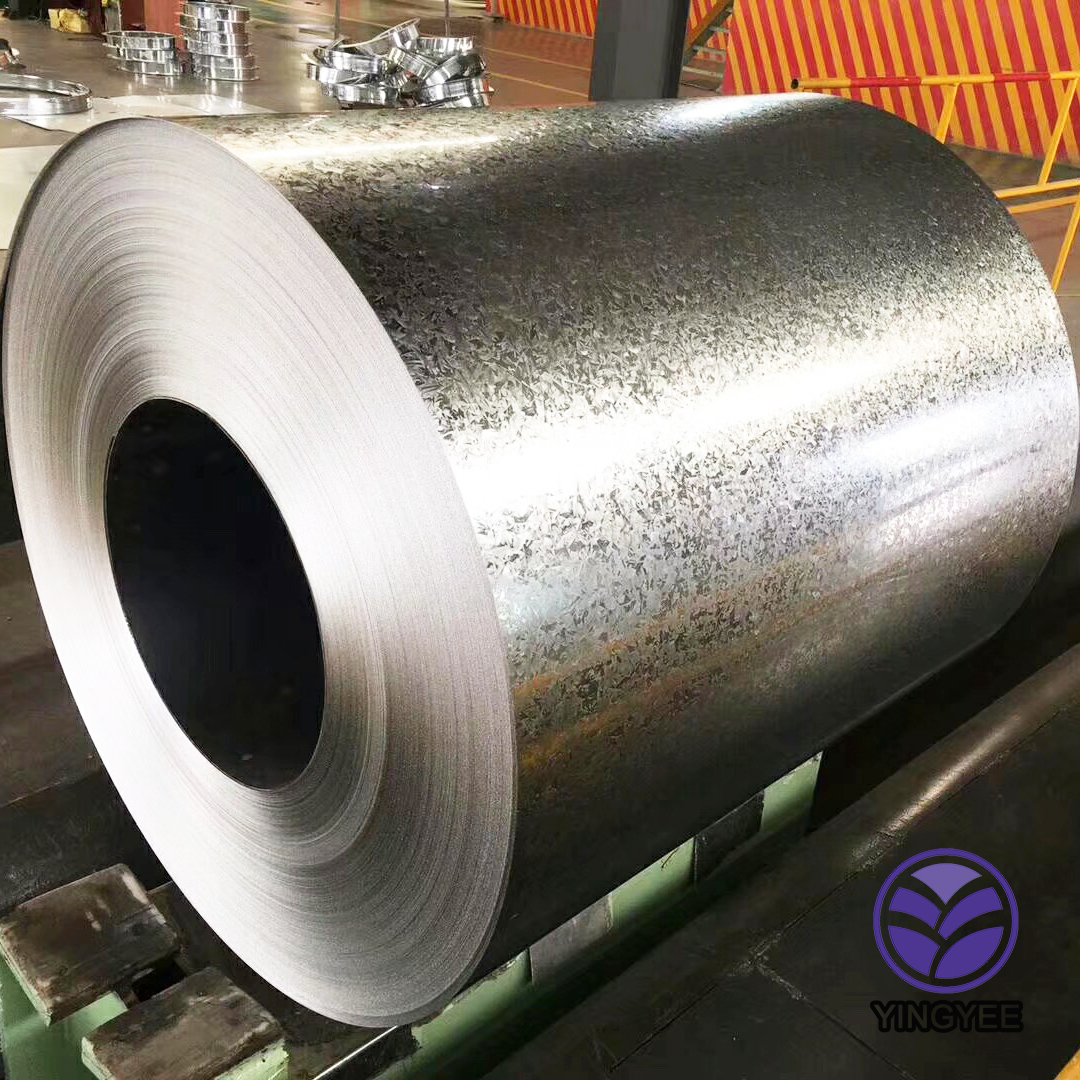

Initially, these machines were limited in scope and efficiency, primarily producing metal pipes through labor-intensive methods. However, technological advancements have ushered in an era of automation and precision. The introduction of computerized numerically controlled (CNC) machines and the widespread use of advanced materials have drastically improved the production rate and quality of pipes. Today’s pipes making machines are capable of producing a wide range of pipe sizes, shapes, and materials, including plastic, steel, and composite materials.

The Technology Behind Pipes Making Machines

Modern pipes making machines are equipped with a variety of technologies that enhance their efficiency and accuracy. The manufacturing process typically involves several stages, including extrusion, molding, and cutting. In the extrusion process, raw materials, such as resin for plastic pipes, are heated and forced through a die to create the desired pipe shape. This method allows for continuous production and minimizes waste.

Furthermore, advanced automation systems control the production line, monitoring parameters like temperature, pressure, and speed to ensure consistency and quality. Many machines also incorporate smart technology, which enables real-time data analysis to optimize production processes and reduce downtime.

Additionally, some pipes making machines are designed to produce pipes with specialized features, such as varying wall thicknesses, added insulation, or composite layers. These capabilities meet the diverse needs of industries ranging from telecommunications to chemical processing.

The Importance of Pipes Making Machines

The significance of pipes making machines cannot be overstated. They play a vital role in meeting the growing global demand for pipes while ensuring high standard quality and durability. With comprehensive production lines, these machines can yield thousands of meters of pipe in a single day, significantly reducing lead times for construction and infrastructure projects.

Moreover, the ability to produce high-strength and corrosion-resistant pipes contributes to the safety and reliability of various systems. Industries such as oil and gas heavily rely on pipes making machines to ensure that pipelines can withstand harsh environmental conditions.

The environmental sustainability aspect also plays an increasingly important role. Many manufacturers are investing in green technologies and processes to minimize waste and energy consumption. Pipes making machines that utilize recycled materials for production contribute to reducing the environmental footprint of pipe manufacturing.

Conclusion

As we look to the future, the role of pipes making machines will only continue to expand. With advancements in technology, including artificial intelligence and machine learning, we can expect even greater efficiencies and innovations in pipe production. This evolution not only supports the burgeoning demand for infrastructure development but also emphasizes the importance of sustainability and quality in manufacturing practices.

In summary, the pipes making machine stands as a crucial element in modern manufacturing, serving diverse industries with precision, efficiency, and reliability. As we embrace these technological advancements, the potential for enhanced production capabilities in the pipe manufacturing industry is limitless.