The Versatility and Importance of Pipe Roll Forming Machines

In the ever-evolving world of manufacturing, one technology that has gained significant traction is the pipe roll forming machine. This advanced machinery plays a pivotal role in the production of high-quality metal pipes, which are essential in numerous industries including construction, automotive, and energy. This article delves into the workings, advantages, and applications of pipe roll forming machines, highlighting their importance in modern manufacturing.

What is a Pipe Roll Forming Machine?

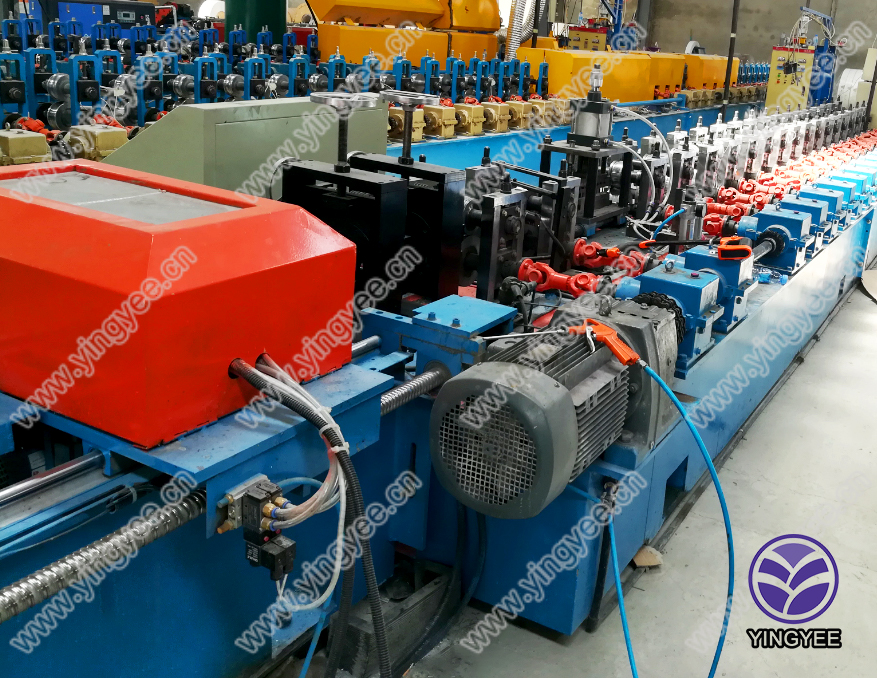

A pipe roll forming machine is a type of industrial equipment designed to shape raw metal into tubes or pipes through a series of rollers. The process begins with flat metal sheets, which are fed into the machine where they are progressively deformed by a set of roller stations. Each station performs a specific part of the shaping process, gradually transforming the flat metal into a cylindrical form. This continuous bending process is highly efficient and allows for the production of various pipe sizes and styles.

The Roll Forming Process

The roll forming process is characterized by its unique ability to create complex shapes while maintaining high levels of precision. The machine employs a series of powered rollers, which apply consistent pressure to the metal sheet, bending it to the desired profile. The process can include various steps

1. Sheet Preparation The flat metal sheet is cut to size and prepared for processing. 2. Roll Forming The sheet is passed through a series of rollers that progressively shape it into a pipe. 3. Welding If necessary, the edges of the pipe are joined together using electric resistance welding, ensuring a strong and seamless product. 4. Finishing Operations The formed pipes may undergo additional processes such as trimming, cleaning, and surface treatment for improved durability and aesthetics.

Advantages of Pipe Roll Forming Machines

The use of pipe roll forming machines offers a plethora of advantages over traditional manufacturing methods, making them a preferred choice for many companies.

1. Efficiency Roll forming is a continuous operation that allows for high production speeds. This efficiency translates to lower labor costs and higher output, essential for meeting market demands.

2. Precision and Consistency The automated nature of roll forming ensures that each pipe produced adheres to specified dimensions and quality standards. This consistency is crucial for industries that require reliable materials.

3. Material Utilization The process minimizes waste as it uses virtually all the material fed into the machine. This aspect not only reduces costs but also promotes sustainability, a growing concern in manufacturing.

4. Versatility Pipe roll forming machines can produce a wide range of pipe sizes, shapes, and wall thicknesses, making them suitable for various applications. Manufacturers can easily adjust the machine settings to accommodate different specifications.

5. Cost-Effectiveness The combination of high-speed production and minimal material waste leads to significant savings on manufacturing costs, providing companies with a competitive edge in pricing.

Applications of Pipe Roll Forming Machines

The versatility of pipe roll forming machines makes them ideal for a multitude of applications across various industries. Some notable uses include

- Construction Steel pipes produced by roll forming are used in structural applications, such as columns and beams, providing the necessary strength and stability for buildings and infrastructure. - Automotive The automotive industry relies on roll-formed pipes for exhaust systems, chassis components, and various structural parts that require lightweight yet strong materials. - Energy In the energy sector, particularly in oil and gas, durable pipe products are essential for transporting fluids and gases safely through pipelines. - Furniture and Design Roll-formed pipes are increasingly being used in furniture design, offering unique shapes and aesthetic appeal for various products.

Conclusion

As industries continue to seek innovative solutions for their manufacturing needs, pipe roll forming machines stand out as a crucial technology. Their efficiency, precision, and versatility make them an integral part of the production process for countless applications. By providing high-quality, cost-effective, and sustainable pipe solutions, these machines not only enhance operational productivity but also contribute significantly to the advancement of modern manufacturing practices. Investing in pipe roll forming machinery is undoubtedly a strategic move for businesses aiming to thrive in today’s competitive landscape.