The Importance of Pipe Thread Rolling Machines in Modern Manufacturing

In today's fast-paced manufacturing environment, efficiency and precision are paramount. One of the unsung heroes in this field is the pipe thread rolling machine, an innovative piece of equipment that enhances the production of threaded pipes with unparalleled accuracy and speed.

Pipe thread rolling machines are designed to forge threads onto pipes through a cold-forming process. Unlike traditional cutting methods, which remove material to create threads, rolling machines deform the metal into the desired shape without generating waste. This not only preserves material but also enhances the physical properties of the pipe, resulting in a stronger and more durable product.

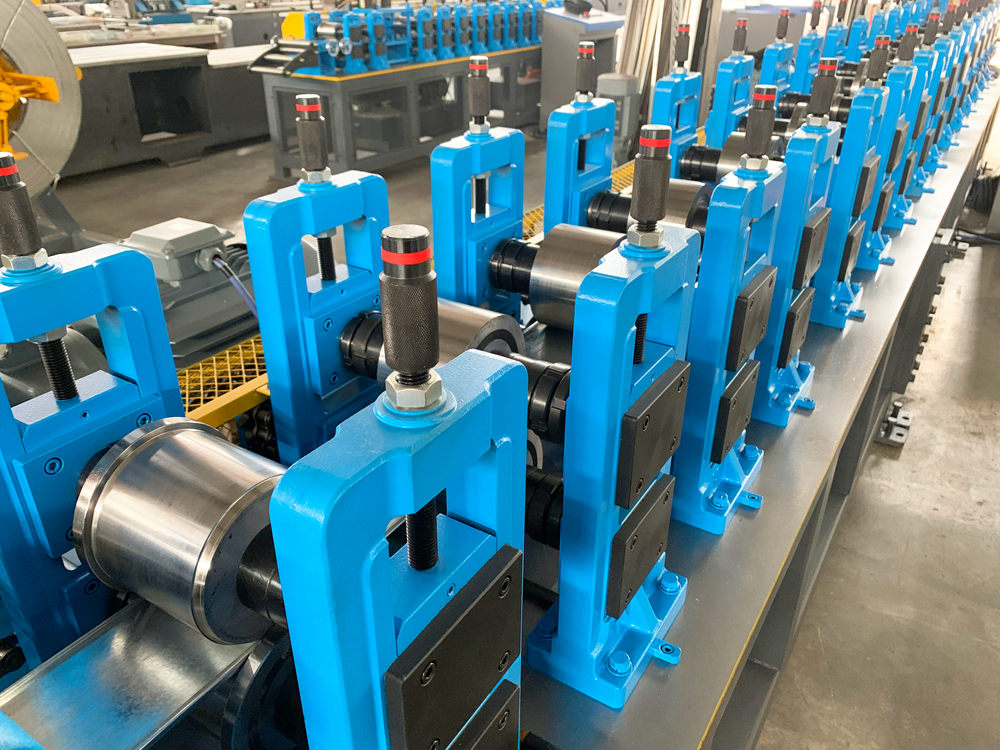

The process begins with a blank pipe being fed into the machine, where it is gripped by rollers that apply pressure. These rollers, often made of hard-grade steel, rotate around the pipe, gradually forming threads as the metal is displaced. The rolling process is fast and efficient, allowing manufacturers to produce large volumes of threaded pipes in a shorter time frame compared to conventional methods.

One of the primary benefits of using pipe thread rolling machines is the enhanced thread quality

. The cold forming process improves the surface finish and dimensional accuracy of the threads, leading to better sealing and fit when the pipes are assembled. This is particularly crucial in industries such as oil and gas, where even the slightest imperfection can lead to leaks and significant safety hazards.Moreover, pipe thread rolling machines are equipped with advanced technology that enables operators to easily adjust parameters such as thread pitch and depth. This flexibility allows manufacturers to produce a wide range of pipe sizes and types, catering to various industry needs. Automation features also contribute to reduced labor costs and increased production rates, making these machines an attractive investment for manufacturers.

Additionally, the use of pipe thread rolling machines contributes to sustainability in manufacturing. The reduction of material waste and increased energy efficiency align with modern practices aiming to minimize the environmental footprint of industrial operations. Companies that adopt these machines not only benefit financially but also enhance their reputation as environmentally responsible entities.

In conclusion, pipe thread rolling machines play a crucial role in modern manufacturing by enhancing efficiency, improving product quality, and promoting sustainability. As industries continue to demand higher production rates and stricter quality standards, the importance of these machines will likely grow. Investing in state-of-the-art pipe thread rolling technology represents a forward-thinking approach for manufacturers seeking to stay competitive in an ever-evolving market. With their ability to deliver precision and performance, pipe thread rolling machines are indeed a vital asset in the landscape of modern industrial manufacturing.