The Pinnacle Rollformer Revolutionizing Metal Fabrication

In the realm of metal fabrication, precision and efficiency are paramount. Among the equipment that has gained significant traction in modern manufacturing, the Pinnacle Rollformer stands out as a beacon of innovation. This advanced machinery is designed to shape and form metal sheets into various profiles, making it an integral tool in industries such as construction, automotive, and aerospace.

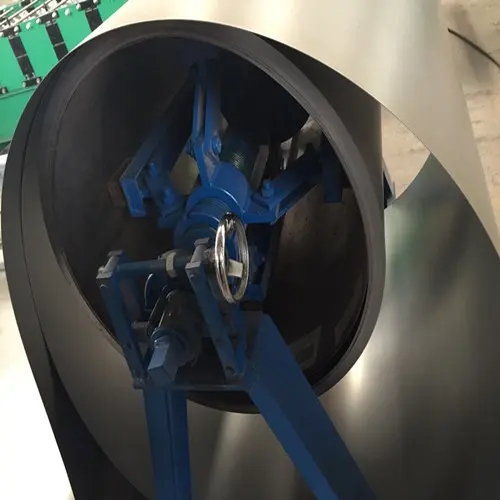

The Pinnacle Rollformer operates on the principle of continuous rolling, where metal strips are passed through a series of rollers that progressively guide and shape the material. This process not only ensures high precision in dimensions but also significantly reduces waste, an essential factor in today’s environmentally conscious manufacturing landscape. The versatility of the Pinnacle Rollformer allows it to produce a wide range of profiles, including roof panels, wall panels, and other structural components.

The Pinnacle Rollformer Revolutionizing Metal Fabrication

Durability and maintenance are also critical aspects of the Pinnacle Rollformer’s design. Constructed from high-quality materials, this machine is built to endure the demanding environment of industrial production. Regular maintenance schedules are simplified as the machine is designed for easy access to key components. This focus on user-friendly maintenance practices helps manufacturers minimize operational interruptions, keeping production lines flowing smoothly.

Moreover, the Pinnacle Rollformer is designed with energy efficiency in mind. As manufacturing operations seek to reduce their carbon footprint, the machine’s low energy consumption standards become a crucial selling point. By optimizing power usage, manufacturers can save on operational costs while contributing to a sustainable future.

Another advantage of the Pinnacle Rollformer is its adaptability to new materials. As the construction industry evolves, new materials are continually being introduced, prompting a need for machinery that can handle these innovations. The Pinnacle Rollformer can be customized to work with various types of metals, including aluminum, steel, and coated metals, making it a versatile solution for diverse applications.

Furthermore, the Pinnacle Rollformer is equipped with safety features designed to protect operators during the fabrication process. Enhanced safety guards, emergency stop mechanisms, and user-friendly controls ensure a secure working environment, allowing operators to focus on the quality of their work without unnecessary distractions.

In conclusion, the Pinnacle Rollformer represents a significant advancement in the field of metal fabrication. With its blend of precision, efficiency, durability, and safety, it is an ideal machine for today’s demanding manufacturing environment. As industries continue to evolve, embracing new technologies and materials, the Pinnacle Rollformer is poised to remain at the forefront, driving innovation and productivity. By investing in such advanced machinery, manufacturers can ensure they are not just keeping pace with the industry but are also paving the way for future advancements in metal processing. As the landscape of fabrication continues to transform, the Pinnacle Rollformer will undoubtedly play a critical role in shaping the future of manufacturing.