The Role of Perforated Cable Tray Roll Forming Machines in Modern Electrical Installations

In the realm of modern electrical installations, cable management plays a crucial role in ensuring safety, efficiency, and organization. One effective solution to this challenge is the use of perforated cable trays, which promote proper cable routing and ventilation. The manufacturing of these trays has been revolutionized by the advent of perforated cable tray roll forming machines, which provide precision, efficiency, and versatility in production.

Understanding Perforated Cable Trays

Perforated cable trays are systems designed to support and manage electrical cables. They come equipped with holes (or perforations) that allow for better air circulation, thereby reducing the risk of overheating and facilitating the attachment of various cable types. This design not only enhances the aesthetic appeal of installations but also properties such as weight reduction and easy access for maintenance.

One of the significant benefits of using perforated trays is their ability to accommodate a variety of cables, including power, communication, and control cables. The perforated design makes it ideal for environments where heat dissipation is critical, such as data centers, industrial facilities, and commercial buildings.

The Functionality of Roll Forming Machines

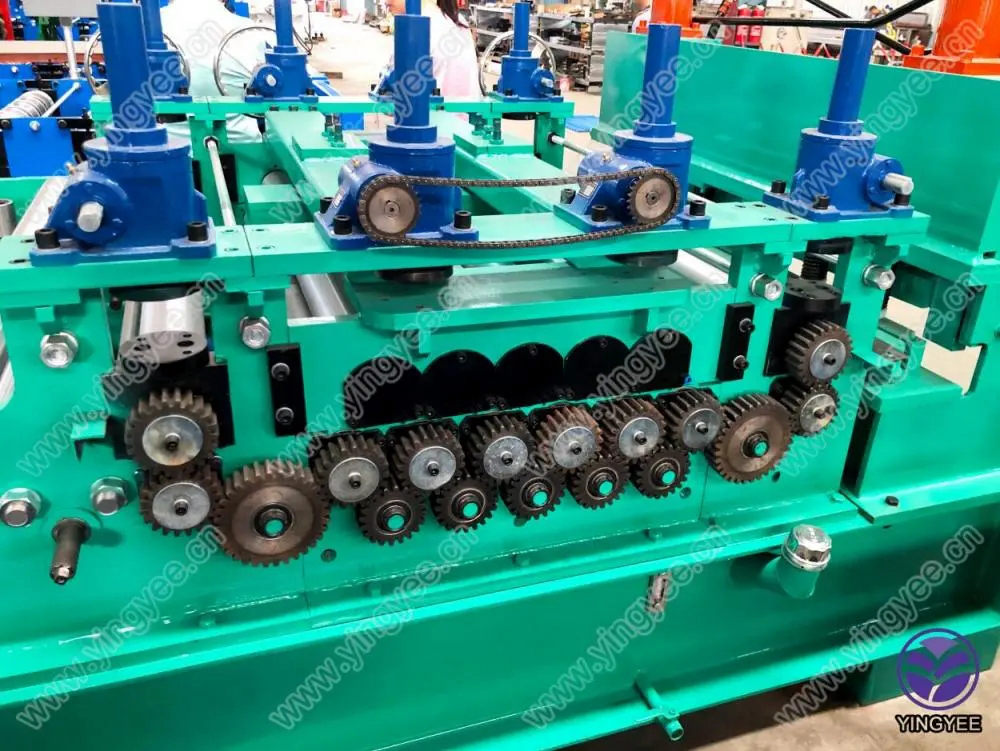

The roll forming process is an efficient method of fabricating metal products, where a continuous strip of metal is fed through a series of rollers to create the desired shape

. For manufacturers of perforated cable trays, roll forming machines are indispensable tools that streamline the production process.1. Precision Engineering Roll forming machines are designed to produce components with exceptional accuracy. Different tooling can create various shapes and sizes of perforated trays, catering to diverse client needs. This precision is vital for ensuring that trays fit perfectly in their intended applications, minimizing installation issues.

2. High Production Speed These machines are capable of producing large volumes of trays in a relatively short period. This speed is essential for manufacturers looking to meet demanding project timelines without compromising quality.

3. Material Versatility Roll forming machines can work with a wide variety of materials, including aluminum, steel, and galvanized metal. This flexibility allows manufacturers to customize the trays according to specific application requirements, such as corrosion resistance or strength.

4. Cost-Effectiveness By optimizing material utilization and reducing waste, roll forming machines help manufacturers minimize production costs. This cost efficiency can be passed on to customers, making perforated cable trays a more affordable solution for cable management.

Innovations and Trends

The technology surrounding perforated cable tray roll forming machines continues to evolve. Modern machines are increasingly equipped with computerized controls and automation, allowing for real-time monitoring and adjustments. This enhances production efficiency and consistency while reducing the likelihood of human error.

Moreover, as environmental considerations become paramount, manufacturers are exploring ways to produce eco-friendly cable trays. Innovations in materials and recycling practices are paving the way for sustainable production methods in the cable management industry.

Additionally, manufacturers are focusing on designs that require less raw material without compromising strength or durability. Such practices not only align with sustainability goals but also contribute to more competitive pricing.

Conclusion

Perforated cable tray roll forming machines are at the forefront of technological advancements in the electrical installation sector. Their ability to produce high-quality, customizable, and cost-effective cable management solutions makes them invaluable to manufacturers and end-users alike. As the demand for organized and efficient cable management systems continues to grow, so too will the relevance of roll forming technology in meeting these needs.

In an age where technology and sustainability go hand-in-hand, the future of cable management looks bright, and perforated cable tray roll forming machines will undoubtedly play a significant role in shaping that future.