The Importance of Outdoor Cable Tray Roll Forming Machines

In the modern era, the efficient management of electrical cables is crucial for various industries, including telecommunications, construction, and data centers. One of the fundamental components in this management system is the cable tray, which provides a secure and organized way to support and route electrical cables. To effectively produce these cable trays, outdoor cable tray roll forming machines play a vital role. This article will explore the significance of these machines, their functionalities, and their impact on various industries.

What is an Outdoor Cable Tray Roll Forming Machine?

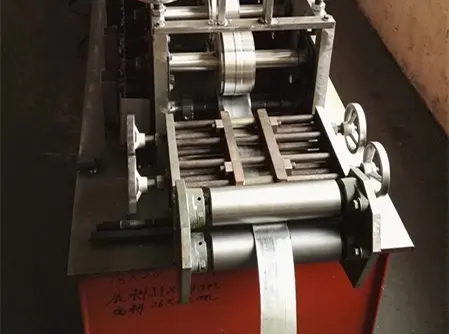

An outdoor cable tray roll forming machine is a specialized piece of industrial equipment designed to manufacture cable trays of different shapes and sizes. Utilizing a continuous forming process, these machines take flat steel coils and progressively shape them into finished products. The result is a durable and reliable cable tray that can withstand outdoor conditions, such as exposure to sunlight, rain, and temperature variations.

These machines are typically equipped with advanced technology to ensure precision and efficiency. They often include features like automated feeding systems, programmable logic controllers (PLCs), and various roll sets that allow the production of different tray types, such as perforated, ladder, and solid bottom trays.

Benefits of Using Outdoor Cable Tray Roll Forming Machines

1. Customization One of the primary advantages of using roll forming machines is the ability to customize products to meet specific project requirements. Manufacturers can adjust the machine settings to produce trays of different widths, heights, and thicknesses, ensuring that the final product fits the intended application perfectly.

2. High Efficiency These machines significantly enhance production efficiency. Unlike traditional manufacturing methods, which can be labor-intensive and time-consuming, roll forming allows for high-speed production. This efficiency not only reduces labor costs but also minimizes waste, making it a more sustainable option.

3. Durability Outdoor cable trays manufactured using roll forming technology are built to last. The process enhances the structural integrity of the trays, making them resistant to wear and tear from environmental factors. This durability ensures long-term reliability, reducing the need for frequent replacements.

4. Cost-Effective Production By streamlining the manufacturing process, outdoor cable tray roll forming machines help in reducing overall production costs. The ability to produce large quantities in a short time frame translates into lower prices for end users, making it an economical choice for electrical contractors and project developers.

5. Versatility These machines can produce various types of cable trays and even adapt to create different auxiliary components, such as brackets and fittings. This versatility allows manufacturers to serve a wide range of industries, including industrial, commercial, and residential sectors.

Applications of Outdoor Cable Tray Roll Forming Machines

Outdoor cable trays are essential in numerous applications. They are commonly used in commercial buildings, data centers, and industrial facilities to manage and protect cabling systems. In telecommunications, cable trays serve as vital components in network infrastructure, ensuring that cables are properly organized and easily accessible for maintenance or upgrades.

Moreover, the growing emphasis on sustainable infrastructure and energy efficiency has increased the demand for quality cable management solutions. As renewable energy projects, such as solar farms and wind energy installations, expand, the role of outdoor cable trays in these systems becomes increasingly significant.

Conclusion

In summary, outdoor cable tray roll forming machines are indispensable tools in the production of high-quality cable trays required for efficient cable management. Their ability to customize products, coupled with high efficiency and durability, makes them a preferred choice across various industries. As technology continues to advance, the demand for innovative solutions in cable management will undoubtedly increase, further solidifying the role of roll forming machines in modern manufacturing. Investing in such technology not only enhances productivity but also contributes to the overall sustainability and efficacy of electrical systems.