The Omega Roll Forming Machine An Overview

The omega roll forming machine is a specialized piece of equipment designed to create omega-shaped profiles from sheet metal. This unique machine is widely used in various industries, including construction, automotive, and manufacturing, due to its efficiency and versatility. With advancements in technology, the omega roll forming machine has become an essential tool in producing high-quality, durable components at a faster rate.

Understanding Roll Forming

Roll forming is a continuous bending operation in which a long strip of metal, typically coiled steel, is passed through a series of rollers. Each roller gradually shapes the metal into the desired profile. The process is known for its efficiency, allowing manufacturers to produce long lengths of metal profiles without joins or welds, which enhances their strength and aesthetic appeal.

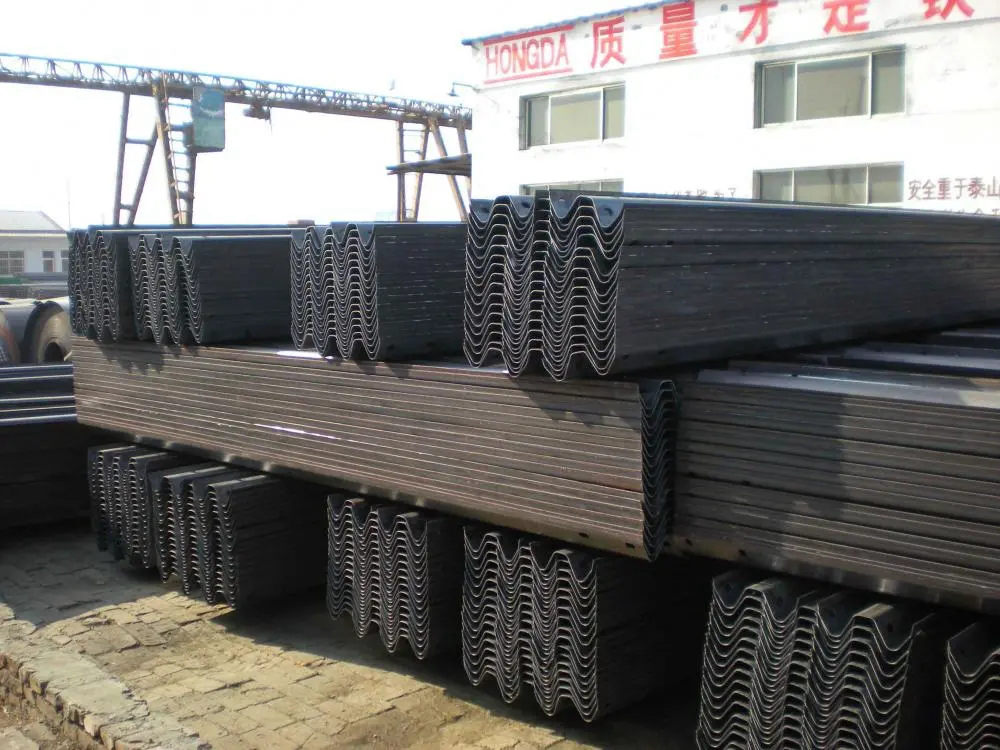

The omega profile, characterized by its distinctive wavy shape resembling the Greek letter Ω, is particularly sought after for its structural integrity and aesthetic properties. It is often used in applications such as roofing systems, wall panels, and even in the automotive industry for reinforcement components.

Key Features of Omega Roll Forming Machines

1. Customization One of the standout features of omega roll forming machines is their ability to be customized based on the specific requirements of a project. Manufacturers can adjust the machine parameters to create varying widths, thicknesses, and lengths of omega profiles. This level of customization helps meet diverse client needs and market demands.

2. High Efficiency Omega roll forming machines are designed to operate at high speeds, significantly reducing production time compared to traditional metal forming processes. With the ability to produce continuous lengths of omega profiles, manufacturers can achieve higher output rates, ultimately increasing productivity.

3. Material Flexibility These machines can work with various materials, including galvanized steel, aluminum, and stainless steel. This flexibility allows manufacturers to choose materials based on the specific requirements of the application, such as weight, corrosion resistance, and strength.

4. Precision Engineering Modern omega roll forming machines incorporate advanced technology to ensure precision in every profile produced. Computer Numerical Control (CNC) systems can be integrated to enhance accuracy, reduce waste, and ensure consistency in production quality. This precision is crucial in applications where tolerances are tight.

5. Durability and Low Maintenance Omega roll forming machines are built for durability, often featuring robust construction that withstands rigorous production demands. Additionally, they generally require lower maintenance compared to other forming machines, which can lead to reduced operational costs over time.

Applications of Omega Profiles

The omega profile's unique shape provides various advantages, making it a popular choice for numerous applications. In construction, omega profiles are commonly used for roofing and cladding systems due to their ability to channel water effectively, preventing leakage. Additionally, they are employed in structural applications, such as supports and reinforcements, thanks to their strength and stability.

In the automotive sector, omega profiles are utilized in manufacturing components like chassis and cross members, where weight savings and strength are critical. Furthermore, the aesthetic appeal of omega profiles makes them suitable for architectural applications, where visual impact is as important as functional performance.

Conclusion

In summary, the omega roll forming machine stands at the forefront of modern manufacturing technology, offering a robust solution for producing high-quality omega profiles efficiently and cost-effectively. Its customization capabilities, operational efficiency, and precision make it an invaluable asset for industries ranging from construction to automotive. As demand for such profiles continues to grow, the role of the omega roll forming machine will undoubtedly remain significant in shaping the future of manufacturing and construction.