The Nut and Bolt Thread Rolling Machine An Essential Tool in Manufacturing

In today's fast-paced manufacturing environment, the demand for precision and efficiency has never been higher. Among the various tools that aid in the production of fasteners, the nut and bolt thread rolling machine stands out as a key piece of equipment that enables manufacturers to produce high-quality threaded components with remarkable speed and accuracy.

Understanding Thread Rolling

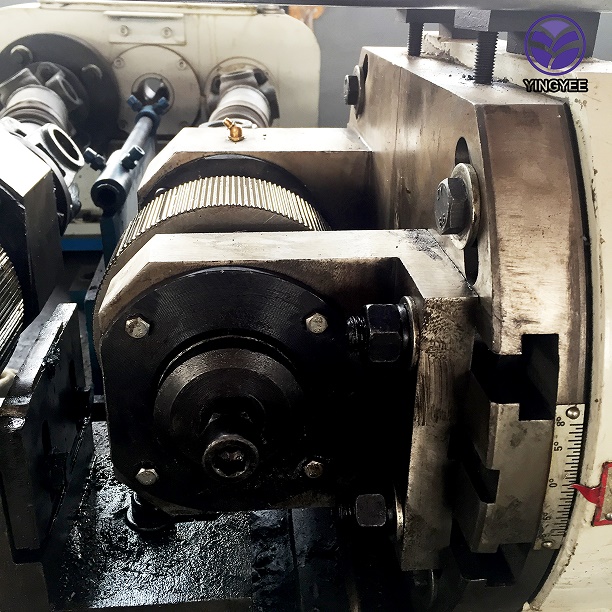

Before delving into the specifics of the thread rolling machine, it is essential to understand the process of thread rolling itself. Unlike traditional cutting methods, which remove material to create threads, thread rolling is a cold forming process. This means that the material is not heated during the procedure, thereby conserving energy and maintaining the metal's integrity. The rolling process involves two or more dies that press against a cylindrical workpiece, deforming the material to create threads. This results in stronger threads due to the alignment of the grain structure of the metal, which is especially beneficial for applications that endure high stress.

Advantages of Thread Rolling

Thread rolling offers numerous advantages that make it a preferred method for producing nuts and bolts. Firstly, it is highly efficient. A thread rolling machine can produce a large volume of components in a relatively short amount of time, significantly reducing production cycles. Furthermore, because there is minimal material waste involved in the process, it is cost-effective. Manufacturers can produce more items from a given amount of raw material, enhancing overall productivity.

Secondly, the mechanical properties of rolled threads are superior to those of cut threads. Rolled threads are typically stronger and more durable, making them better suited for various industrial applications, from automotive to aerospace. The absence of cutting marks and the smooth surface finish achieved through thread rolling lead to better fatigue resistance and overall performance of the fasteners.

Features of Nut and Bolt Thread Rolling Machines

Nut and bolt thread rolling machines come equipped with several key features that enhance their functionality. Most machines are designed with adjustable dies that can accommodate various thread sizes and shapes, making them versatile for different production requirements. Additionally, high-speed operation capabilities allow manufacturers to optimize their output without compromising quality.

Modern thread rolling machines are also integrated with advanced technology such as Computer Numerical Control (CNC), which ensures precise movements of the dies. This CNC technology allows for the easy programming of different threading specifications, minimizing the need for manual adjustments and reducing the potential for human error. As a result, manufacturers can achieve higher levels of consistency and repeatability in their products.

Applications in Industry

The applications of nut and bolt thread rolling machines are extensive. They are widely used in the automotive industry for the production of engine bolts, wheel bolts, and other critical components. In the construction sector, these machines help manufacture connections for steel structures, scaffolding, and various heavy machinery. Additionally, the growing demand for high-quality fasteners in the aerospace sector further underscores the importance of these machines in producing components that meet strict safety and regulatory standards.

Conclusion

In conclusion, the nut and bolt thread rolling machine is an invaluable asset in modern manufacturing. With its ability to produce high-strength, precise threaded components efficiently, it plays a crucial role in a wide range of industries. As technology continues to advance, these machines are likely to become even more sophisticated, further enhancing their capabilities. For manufacturers seeking to maintain a competitive edge, investing in state-of-the-art thread rolling machines will undoubtedly be a strategic decision that pays dividends in quality, efficiency, and production speed.