The Evolution of Nut and Bolt Manufacturing The Role of Large Span Roll Forming Machines with Bending Capabilities

In the competitive landscape of manufacturing, the production of high-quality nuts and bolts is paramount to various industries, including automotive, construction, and machinery. As the demand for these fasteners continues to rise, manufacturers are increasingly turning to advanced technology to improve efficiency and precision. One such innovation is the large span roll forming machine combined with a bending machine, which is revolutionizing the way nuts and bolts are produced.

Understanding Roll Forming

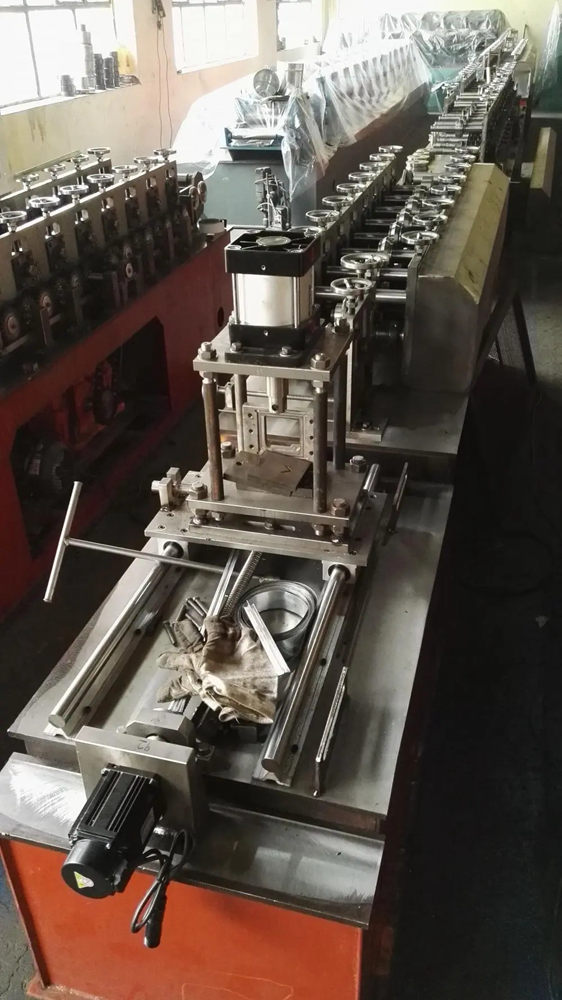

Roll forming is a continuous bending process in which flat strips of material, usually metal, are fed through a series of rollers that progressively shape the material into a desired cross-section. This method is favored for its ability to produce consistent and uniform products, making it ideal for high-volume production runs. The precision attained with roll forming not only reduces material waste but also enhances the overall quality of the end product.

Benefits of Large Span Roll Forming Machines

Large span roll forming machines are designed to accommodate wider and thicker materials, allowing manufacturers to create heavy-duty fasteners that meet stringent industry standards. The benefits of this machinery include

1. Increased Production Capacity Large span machines can handle larger coils of metal, which means fewer changeovers and increased uptime. This translates to higher output rates, essential for meeting modern manufacturing demands.

2. Enhanced Precision The advanced design of these machines ensures that the dimensional tolerances of the rolled products are maintained within tight specifications, leading to fewer defects and reworks.

3. Versatility These machines can be easily reconfigured to create various types of fasteners, including different sizes and shapes of nuts and bolts. This flexibility allows manufacturers to respond quickly to market changes or customer requirements.

4. Cost Efficiency By reducing raw material waste and labor costs associated with manual processes, large span roll forming machines offer significant savings over time.

The Integration of Bending Machines

To further enhance the production process, many manufacturers are integrating bending machines with their roll forming equipment. This integration allows for the simultaneous shaping and bending of materials, streamlining production and reducing handling times.

Key Features of Bending Machines

1. Multifunctionality Bending machines can perform multiple tasks, from simple bends to complex multi-radius formations. This functionality eliminates the need for separate bending operations, saving both time and labor.

2. Automation Modern bending machines are often equipped with computer numerical control (CNC) systems, which provide precise control over bending angles and depths. This automation ensures consistent quality and reduces the likelihood of human error.

3. Higher Tolerance Levels Advanced bending technology allows manufacturers to achieve higher tolerance levels, which are critical for components that must fit precisely in assemblies.

Application in Nut and Bolt Manufacturing

The combination of large span roll forming machines and bending machines is particularly beneficial for producing nuts and bolts with complex geometries and high strength specifications. For instance, the production of hexagonal bolts, which require precise angles and uniformity, is streamlined by these machines.

Moreover, with the increasing trend toward lightweight materials in industries such as automotive, the ability to shape thinner materials without compromising strength is essential. The roll forming and bending technology allows manufacturers to adapt to these trends rapidly, producing lighter yet robust fasteners that meet modern industry standards.

Conclusion

As the manufacturing landscape continues to evolve, the integration of advanced machinery like large span roll forming machines with bending capabilities is transforming the production of nuts and bolts. By offering increased efficiency, enhanced precision, and greater versatility, these machines are enabling manufacturers to meet the growing demands of various industries while maintaining high quality standards. The future of fastener manufacturing looks promising as more companies embrace these technologies, driving innovation and productivity in the sector.