The Advancements in Noise Barrier Cold Bending Machines

In recent years, the growing emphasis on noise pollution control has fueled the development of innovative technologies in various industries. Among these advancements, the noise barrier cold bending machine has emerged as a crucial tool in the manufacturing of noise barriers, which are essential for mitigating sound pollution, particularly in urban environments.

Noise barriers, often seen along highways or near railways, serve as physical barriers that absorb or deflect sound waves, significantly reducing the noise that reaches residential areas or sensitive environments. As cities expand and transportation networks grow, the demand for effective noise control measures has never been higher. This is where the cold bending machine plays a vital role.

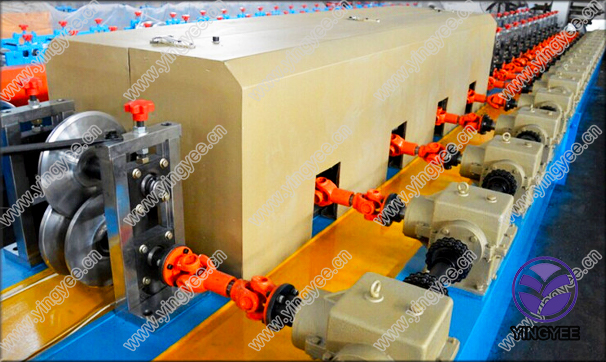

The cold bending machine is designed to shape metal sheets into various forms without the application of heat. This process not only preserves the material's properties but also enhances its structural integrity. The flexibility of cold bending allows manufacturers to create noise barriers with complex designs that can meet specific aesthetic and functional requirements. Furthermore, the cold bending process is more energy-efficient and environmentally friendly compared to traditional hot bending methods.

One notable advantage of using a cold bending machine for noise barriers is the precision offered by modern computerized systems. These machines are equipped with advanced software that allows for exact measurements and customization. Manufacturers can produce noise barriers tailored to specific locations, considering factors such as local noise levels, wind conditions, and even architectural styles. This level of customization ensures that the noise barriers not only perform effectively but also blend seamlessly into the surrounding environment.

Additionally, the materials used in noise barrier construction have evolved significantly. The cold bending machine can work with a variety of materials, including steel, aluminum, and composite panels. These materials are chosen for their durability and acoustic performance, providing long-lasting solutions to noise pollution issues. The ability to work with different materials also enables manufacturers to innovate designs that are not only functional but also attractive, enhancing the landscape of urban areas.

Another important aspect of noise barrier cold bending machines is their efficiency. In a world that increasingly prioritizes sustainability, the ability to produce noise barriers quickly without compromising quality is crucial. These machines can handle high volumes of production while minimizing waste, making them an economical choice for manufacturers. The combination of speed and precision reduces lead times and costs for construction projects, allowing for quicker responses to community noise issues.

The integration of automation and robotics into cold bending machines further streamlines the manufacturing process. Automated systems can handle loading, bending, and unloading, reducing the need for manual labor and increasing overall safety. This technological advancement not only boosts productivity but also allows human workers to focus on more complex tasks that require critical thinking and creativity.

In conclusion, the noise barrier cold bending machine represents a significant leap forward in the manufacturing of noise control solutions. By offering precision, efficiency, and sustainability, these machines are helping to create safer and quieter urban environments. As cities continue to grow and evolve, the importance of effective noise barriers will only increase, making the role of cold bending technology paramount in addressing the challenges of noise pollution today. The future holds exciting potential for further innovations in this field, promising even more effective and aesthetically pleasing solutions for sound mitigation.