Understanding Noise Barrier Cold Bending Machines Innovations in Construction

Noise pollution has become an increasingly pressing concern in urban environments. As cities expand and construction projects proliferate, the need for effective noise reduction solutions has never been greater. One innovative solution that has gained traction in recent years is the noise barrier cold bending machine, a technological advancement that plays a pivotal role in constructing robust noise barriers. This article delves into the significance, functionality, and benefits of these machines in modern construction practices.

What Are Noise Barriers?

Noise barriers are structures designed to block or reduce the transmission of sound waves, particularly in locations near highways, railways, and industrial areas. They are essential in enhancing the quality of life for residents in nearby areas by minimizing sound pollution. These barriers can be made from various materials, including earth, concrete, wood, and specialized composites. However, the efficiency and aesthetic appeal of these barriers largely depend on advanced manufacturing techniques.

The Role of Cold Bending Machines

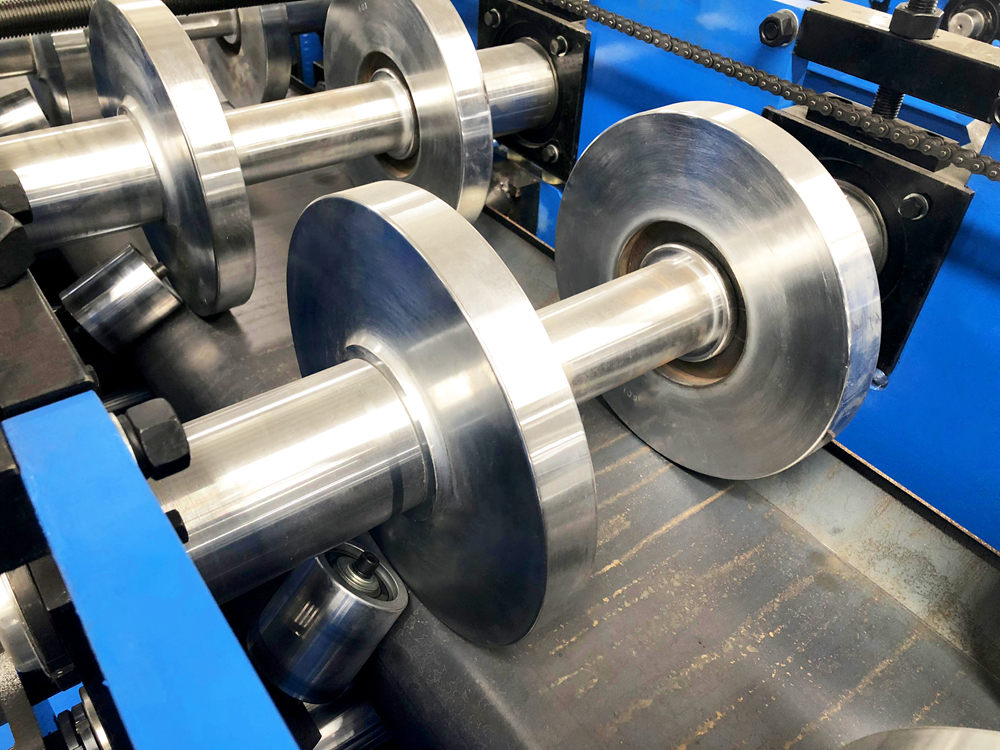

Cold bending machines are specialized equipment used to bend materials, typically steel, without the application of heat. The cold bending process preserves the integrity of the material, maintaining its strength and durability while allowing for precise shapes and designs. When applied to noise barrier construction, these machines facilitate the creation of components that can effectively absorb or deflect sound.

The process of using a cold bending machine involves placing steel sheets or profiles into the machine, which then applies controlled pressure to bend the material into the desired shape without compromising its structural integrity. This method of bending is crucial for producing the intricate designs required for modern noise barriers, enabling manufacturers to create aesthetically pleasing and functional structures.

Advantages of Cold Bending Technology

1. Material Efficiency One of the significant benefits of using cold bending machines in constructing noise barriers is material efficiency. Traditional methods often result in waste due to the need for extensive welding and cutting. Cold bending minimizes material waste, making the construction process more sustainable and cost-effective.

2. Enhanced Durability The cold bending process ensures that materials retain their strength and resistance to environmental factors. Noise barriers often face harsh weather conditions, and the durability provided by cold bending technology contributes to the longevity of these structures.

3. Design Flexibility Cold bending machines allow for greater design flexibility, enabling manufacturers to create customized shapes and profiles that can better meet specific acoustic requirements or aesthetic preferences. This flexibility is vital when constructing noise barriers in urban areas where design considerations are paramount.

4. Speed of Production The efficiency of cold bending machines significantly reduces the manufacturing time of noise barrier components. Faster production means quicker project turnaround and the ability to meet tight construction deadlines.

5. Cost-Effectiveness By reducing material waste, speeding up production, and enhancing durability, cold bending technology can lead to substantial cost savings over time. This financial efficiency is attractive to contractors and municipalities working within budget constraints.

Conclusion

As urbanization continues to rise and noise pollution becomes a significant issue, the importance of effective noise barrier solutions cannot be understated. The adoption of noise barrier cold bending machines represents a notable advancement in the construction industry, combining efficiency, durability, and design flexibility. With their ability to produce high-quality, customized noise barriers quickly and sustainably, these machines are set to play a critical role in enhancing urban living conditions and minimizing the impact of noise pollution in the years to come.

In summary, noise barrier cold bending machines are not just pieces of equipment; they symbolize a shift towards innovation and sustainability in construction practices. As we continue to face the challenges posed by urban development, embracing these advancements will pave the way for quieter, more harmonious living environments.