The Benefits and Mechanism of Noise Barrier Cold Bending Machines

In today's rapidly urbanizing world, noise pollution has emerged as a significant environmental concern. As a result, the construction of noise barriers has become essential to mitigate noise pollution from highways, railways, and industrial zones. Among the various technologies employed in the creation of these barriers, the use of cold bending machines for noise barrier manufacturing stands out due to their efficiency and versatility. This article explores the advantages and working principles of noise barrier cold bending machines, shedding light on their role in creating an eco-friendly and quiet environment.

Understanding Noise Barriers

Noise barriers are structures designed to shield sensitive areas, such as residential neighborhoods, schools, and parks, from unwanted noise. Typically made from solid materials like concrete, wood, and various composites, these barriers can effectively reduce noise levels by reflecting and absorbing sound waves. However, the manufacturing process of these barriers requires advanced machinery capable of producing efficient, high-quality components that meet specific design and durability requirements.

The Role of Cold Bending Machines

Cold bending machines play a pivotal role in the fabrication of noise barriers. These machines use a process that allows steel and other materials to be bent into desired shapes without the application of heat. This method not only preserves the material's strength but also enhances its structural integrity, making it ideal for use in noise barriers, which need to withstand various environmental conditions while providing effective sound insulation.

Advantages of Cold Bending

1. Material Preservation One of the primary benefits of cold bending technology is that it maintains the inherent properties of the metal. By avoiding heat exposure, the machine ensures that the steel retains its toughness and durability, which is crucial for outdoor installations subject to weather fluctuations.

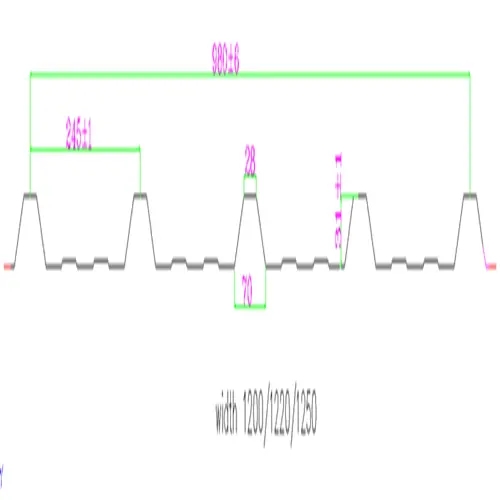

2. Precision and Customization Cold bending machines are designed with advanced control systems that allow for precision bending and customization. This flexibility enables manufacturers to produce noise barriers in various shapes and sizes tailored to specific site requirements. Whether it’s a curved design to blend seamlessly into the natural landscape or a straight barrier to block a highway sound, cold bending technology makes it possible.

3. Efficiency and Speed The cold bending process is generally faster than traditional techniques, such as hot bending or welding. This efficiency translates into reduced production times and lower labor costs. Consequently, manufacturers can meet demand more quickly, which is particularly beneficial in projects with tight deadlines.

4. Reduced Waste Cold bending methods generate less waste compared to other fabrication processes. This not only contributes to cost savings but also supports environmental sustainability initiatives, as less material waste means a lower carbon footprint.

5. Lower Energy Consumption Unlike hot bending, which requires significant energy input for heating the material, cold bending is more energy-efficient. This aspect makes it an appealing option for manufacturers looking to minimize operational costs and enhance their sustainability efforts.

Conclusion

In summary, noise barrier cold bending machines represent a significant advancement in the manufacturing of sound barriers. Offering benefits such as material preservation, precision customization, efficiency, reduced waste, and lower energy consumption, these machines are vital for producing high-quality noise barriers that effectively protect communities from noise pollution. As urban areas continue to expand, the need for innovative and efficient technologies in noise barrier production becomes increasingly important. By investing in cold bending technology, manufacturers can ensure that they contribute positively to environmental sustainability while meeting the needs of urban populations seeking relief from the incessant clamor of modern life. As we move forward, the importance of these machines in the quest for quieter urban environments will only grow, paving the way for a more peaceful coexistence between human activity and nature.