The Evolution and Importance of Metal Stud Forming Machines

In the realm of modern construction and manufacturing, metal stud forming machines play a crucial role. These machines are engineered to produce metal studs that form the framework of various structures—ranging from residential homes to larger commercial buildings. As the construction industry evolves, the demands for efficient and versatile equipment have surged, making metal stud forming machines an essential asset in contemporary engineering practices.

The Basics of Metal Stud Forming Machines

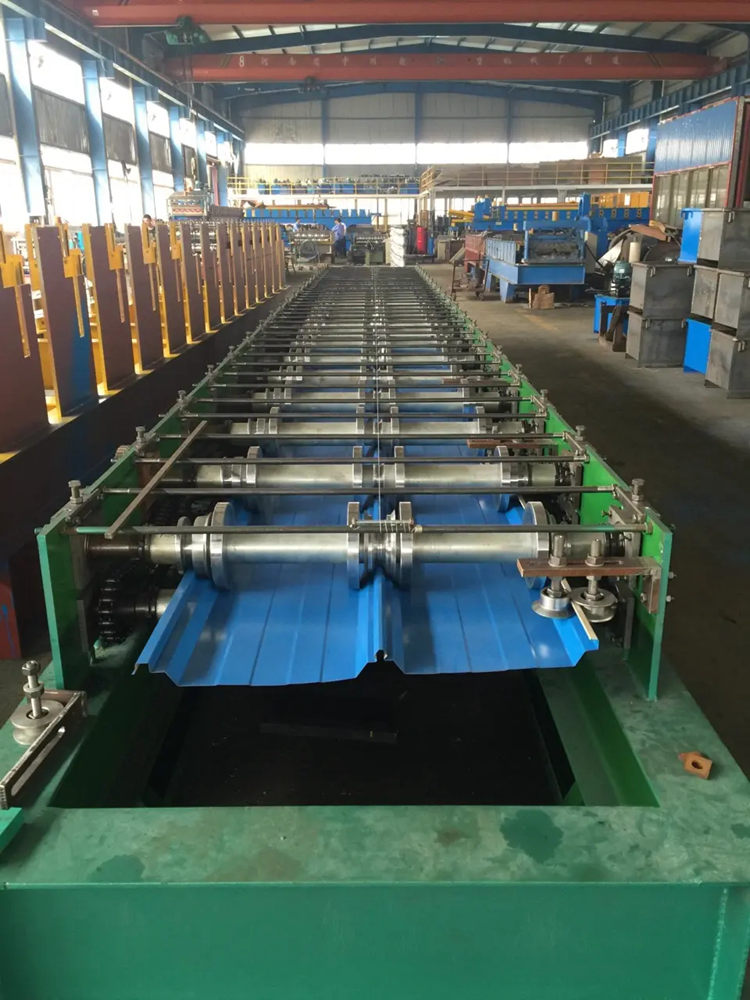

Metal stud forming machines are specialized equipment designed to convert flat metal sheets into metal studs of various shapes and sizes. This process involves several stages, including decoiling, feeding, forming, cutting, and sometimes even punching holes for electrical wiring or plumbing. The versatility of these machines allows them to create lightweight yet durable studs, which are often made from steel or galvanized metal.

The design of metal studs offers numerous advantages over traditional wooden frames. Metal studs are resistant to pests, rot, and fire, making them a safer choice in various applications. Additionally, they are typically lighter than wood, which simplifies transportation and reduces labor costs during installation.

Advancements in Technology

Recent advancements in technology have significantly enhanced the functionality and efficiency of metal stud forming machines. The integration of computer numerically controlled (CNC) systems allows for high precision and automated operations, minimizing human error and improving production speed. Modern machines can produce thousands of studs in a single day while maintaining consistent quality.

The introduction of software solutions has also revolutionized the design process. Engineers and architects can now create detailed blueprints that can be directly fed into the forming machines, ensuring that the products meet specific design criteria. This seamless integration between design and manufacturing not only streamlines operations but also enables more innovative structures that were previously difficult to achieve.

Sustainability in Metal Construction

As environmental concerns rise, the construction industry is increasingly looking toward sustainable methods. Metal stud forming machines contribute to this movement by allowing for the use of recycled materials in the production process. Steel, one of the primary materials used for metal studs, can be recycled without losing its strength, making it an eco-friendly choice.

Additionally, metal studs enable better energy efficiency in buildings. Their reflective surfaces can enhance insulation and reduce energy consumption for heating and cooling purposes. Therefore, investing in metal stud technology aligns with the broader goal of sustainable development within the construction sector.

The Future of Metal Stud Forming Machines

Looking ahead, the future of metal stud forming machines appears bright. As construction methods continue to evolve, the demand for lightweight, fire-resistant, and sustainable building materials will likely increase. Manufacturers are already exploring innovations such as smart forming machines that incorporate artificial intelligence to optimize production and quality control.

Furthermore, the global push for prefabrication in construction is leading to an increased interest in modular building techniques. Metal studs are an integral part of these systems, providing the frameworks for pre-manufactured components that can be assembled on-site with minimal labor.

Conclusion

In conclusion, metal stud forming machines are not just a piece of equipment; they are a driving force behind modern construction practices. Their ability to produce efficient and durable products coupled with technological advancements positions them at the forefront of the industry. As we move toward a more sustainable and efficient future in construction, metal stud forming machines will undoubtedly play a pivotal role in shaping the landscapes of our cities and communities. Embracing these innovations not only contributes to better building practices but also promotes a more sustainable way of living.