Understanding Metal Stud and Track Roll Forming Machines for Sale

In the construction industry, the demand for high-quality metal framing solutions has surged over the years. Among the various tools and machinery that facilitate this process, metal stud and track roll forming machines have gained immense popularity. This article aims to provide insights into these machines, their functions, benefits, and considerations when purchasing them.

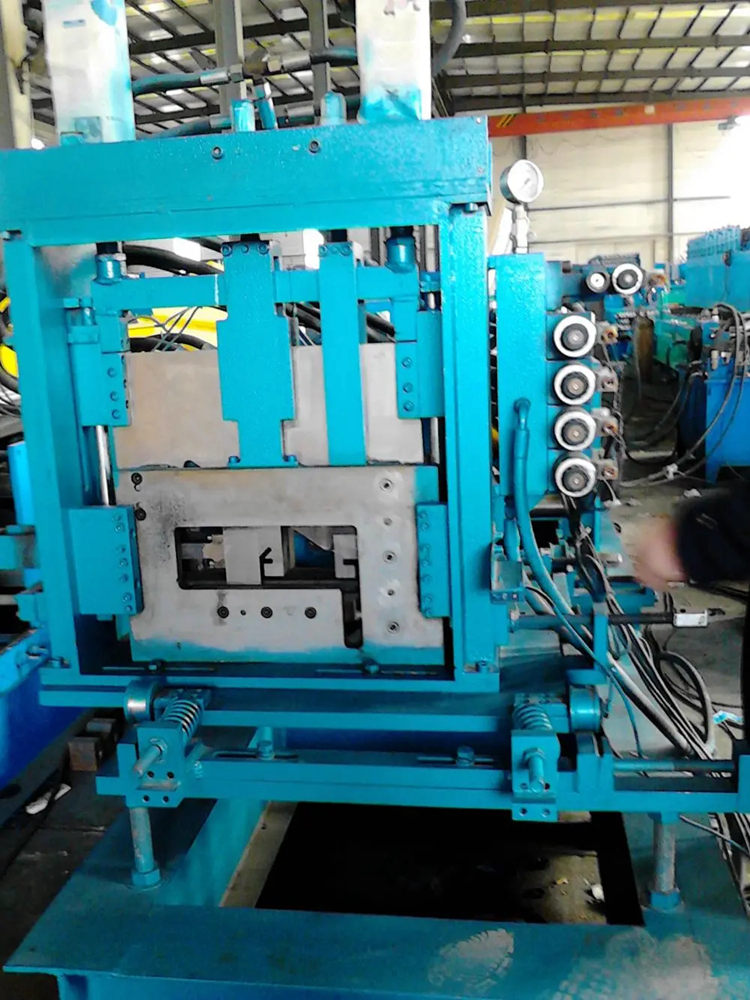

What is a Metal Stud and Track Roll Forming Machine?

A metal stud and track roll forming machine is a specialized piece of equipment designed to produce metal studs and tracks used in the framing of buildings. These machines shape cold-rolled steel or other metal sheets into desired profiles, making it easier for builders to create strong, durable structures with minimal effort. The roll forming process involves feeding metal coils through a series of rollers that gradually shape the metal into the specified design.

Key Features and Components

1. Roll Forming System The core of the machine, the roll forming system, consists of multiple rollers that progressively shape the metal. Each roller alters the shape slightly until the desired profile is achieved.

2. Cut-Off Mechanism Once the metal is formed into the desired shape, it is cut to length by the cut-off mechanism. This component can be hydraulic or mechanical, depending on the model.

3. Control Panel Modern machines come equipped with digital control panels that allow operators to set parameters such as speed, length, and size, ensuring precision in production.

4. Material Handling System Automated material handling systems enhance efficiency by ensuring the consistent feed of metal coils into the machine.

5. Quality Control Features High-end machines may include integrated quality control systems that monitor the thickness and shape of the studs during production.

Benefits of Using Metal Stud and Track Roll Forming Machines

1. Cost-Effective Production These machines significantly reduce labor costs by automating the production process. They can produce large quantities of studs and tracks in a short timeframe, making them ideal for large construction projects.

2. Precision and Consistency The automated nature of roll forming machines ensures that each piece produced is uniform in size and shape, reducing waste and ensuring high-quality outputs.

3. Versatility Many roll forming machines are capable of producing a variety of profiles, which makes them versatile tools for different construction needs. This flexibility allows manufacturers to meet the diverse demands of their clients.

4. Space Efficiency Metal studs are lightweight compared to traditional wooden framing, which helps save space on construction sites. Using metal framing can also lead to reduced building weight and subsequently lower foundation costs.

5. Sustainability Metal is a recyclable material, and using metal studs promotes sustainable building practices. Additionally, they are resistant to rot, pests, and fire, enhancing the longevity of the structures they support.

Considerations When Purchasing a Roll Forming Machine

1. Production Capacity Buyers should assess their production needs and select a machine that can meet these requirements in terms of speed and output volume.

2. Customization Options Evaluate whether the machine can produce customized profiles, as this may be essential for certain projects.

3. Space Requirements Ensure that the machine fits within your operational space, considering both the footprint of the machine and the necessary workspace for operators.

4. Budget Roll forming machines vary in price based on features and capabilities. It's essential to balance the investment with expected returns and operational savings.

5. After-Sales Support Consider the availability of customer support and replacement parts from the manufacturer. A company that provides excellent service can greatly reduce downtime.

Conclusion

Investing in a metal stud and track roll forming machine can be a game-changer for construction businesses looking to enhance productivity, reduce costs, and deliver high-quality results. By understanding the features, benefits, and key considerations when purchasing such machinery, businesses can make informed decisions that contribute to their success in the competitive construction industry. Whether you are a seasoned builder or just starting, exploring options for a roll forming machine is a strategic step toward innovation and efficiency.