The Metal Stud and Track Roll Forming Machine A Pillar of Modern Construction

In the dynamic world of construction, efficiency and precision are vital. One innovative solution that has redefined the industry is the metal stud and track roll forming machine. This sophisticated piece of equipment is designed to produce metal studs and tracks that are essential for the framework of walls and ceilings in both residential and commercial buildings.

The role of metal studs in construction has gained significant traction over the years, largely due to their durability, lightweight nature, and resistance to pests and fire. Unlike traditional wooden studs, metal studs are non-combustible and do not warp, making them a preferred choice among architects and builders. Their use has led to a notable shift in how structures are framed, allowing for faster builds and reduced waste.

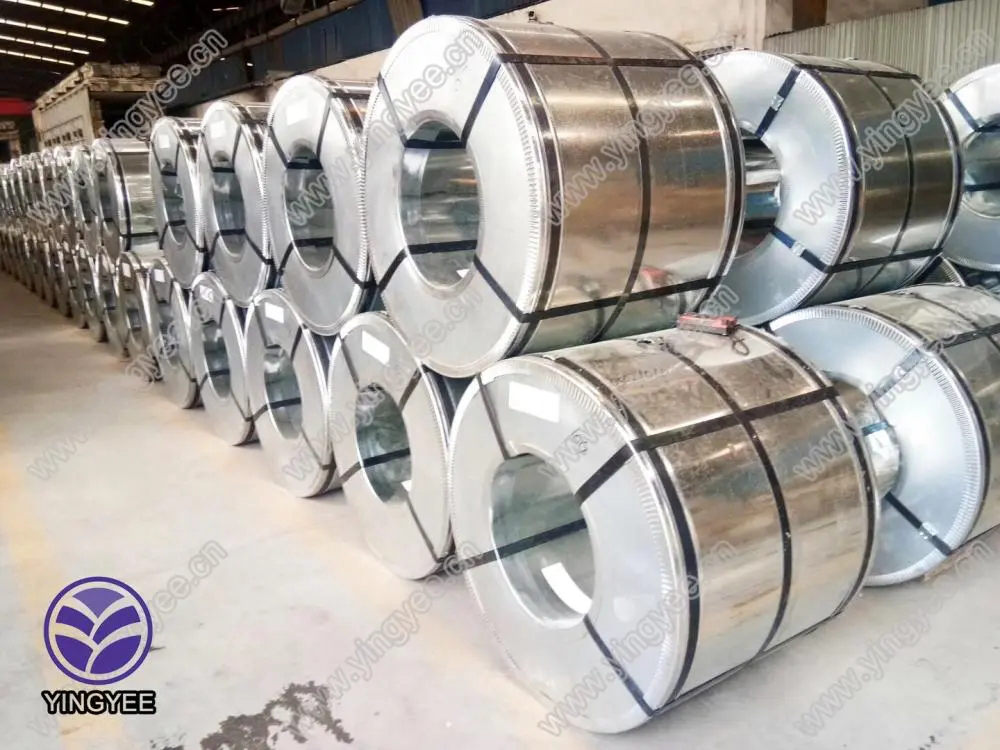

The metal stud and track roll forming machine operates on a simple yet effective principle. Raw metal coils are fed into the machine, which then forms them into specific shapes through a series of rollers and dies. This process is known as roll forming. The machine can produce various profiles, including C-studs, U-tracks, and other custom designs, on-demand, which drastically cuts down lead times compared to traditional manufacturing processes.

One of the most significant advantages of using a roll forming machine is its efficiency. High-speed operations enable the production of thousands of studs and tracks in a single day, thus maximizing productivity. Additionally, the precision of the machine ensures that each piece meets exact specifications, minimizing discrepancies and the need for rework. This precision not only supports structural integrity but also contributes to the overall quality of construction projects.

Another key benefit is the machine's ability to adapt to changing market demands. As construction styles and requirements evolve, manufacturers can easily modify their roll forming machines to create new profiles or adjust sizes. This flexibility is crucial in today’s fast-paced construction environment where customization is often required to meet specific design aesthetics or building codes.

Moreover, investing in a metal stud and track roll forming machine presents a significant opportunity for cost savings. By producing metal components in-house, construction companies can reduce material costs and eliminate transportation expenses associated with sourcing pre-manufactured products. This not only lowers overall project costs but also allows for better inventory management.

Finally, the move toward sustainable building practices is seamlessly integrated with the use of metal studs. Made primarily from recycled materials, steel studs contribute to a reduced carbon footprint, aligning with the industry's shift towards greener construction solutions.

In conclusion, the metal stud and track roll forming machine epitomizes the advancements in modern construction technology. By enhancing efficiency, precision, and sustainability, it has become an indispensable tool for builders and developers striving to meet the increasing demands of the industry while maintaining high-quality standards. As the construction landscape continues to evolve, the importance of such machines will only grow, paving the way for innovative building practices and improved structures.