Metal Strut Channel Roll Forming Machine A Critical Tool for Modern Construction

In the modern construction industry, efficiency and quality are paramount. Among the vital equipment used to meet these demands is the metal strut channel roll forming machine. This specialized machinery plays a crucial role in the production of strut channels, which are essential components in the structural framework of buildings, HVAC systems, and various mechanical installations. This article explores the significance, functionality, and benefits of metal strut channel roll forming machines.

Understanding Strut Channels

Strut channels, also known as metal framing channels, are versatile components used for supporting and securing various systems such as piping, electrical conduits, and framing structures. They are typically made from materials such as galvanized steel or aluminum, ensuring both strength and corrosion resistance. The design of these channels allows for easy attachment of other items, making them indispensable in construction and maintenance projects.

The Role of Roll Forming Machines

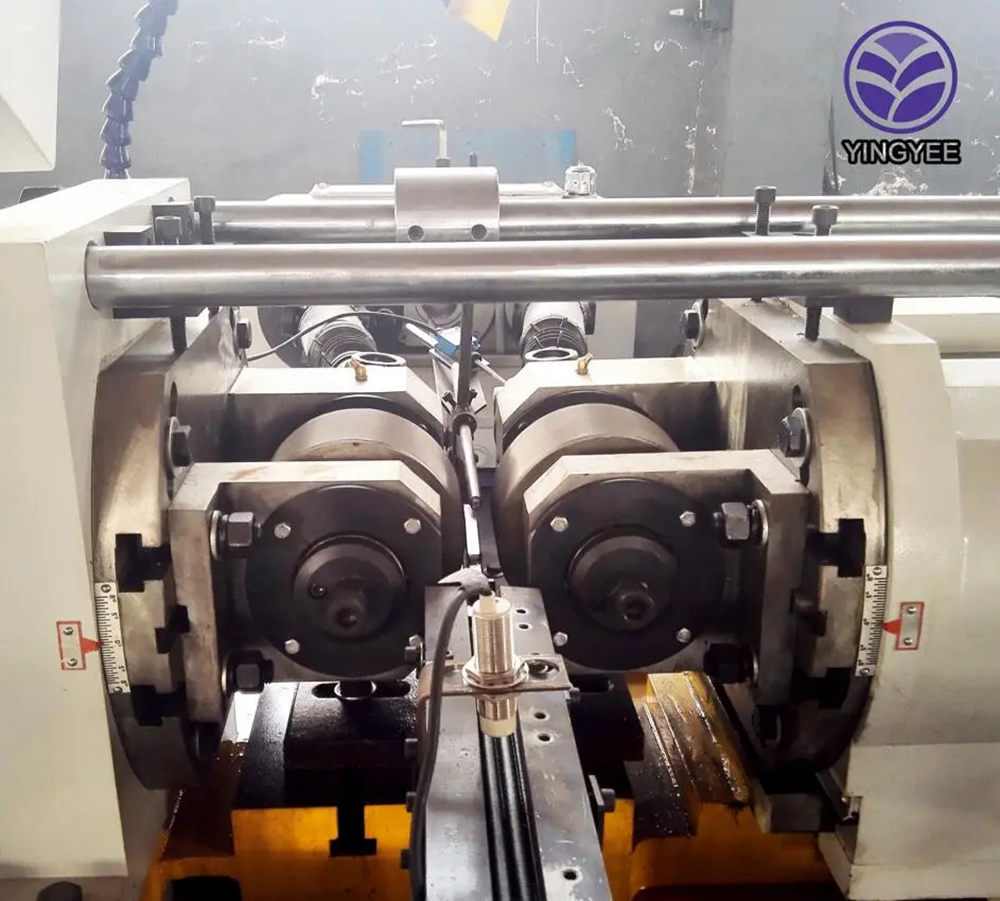

Roll forming is a continuous manufacturing process that transforms long strips of metal into specific shapes through a series of rollers. The metal strut channel roll forming machine uses this technique to produce channels with precision and consistency. The process begins with feeding a flat metal sheet or coil into the machine, which is then shaped through progressive bending as it passes through a series of rollers.

The roll forming machine can be customized to create various channel sizes and profiles, catering to the specific requirements of different construction projects. This flexibility makes it an asset in manufacturing environments, where adaptability and efficiency are crucial.

Key Features of Roll Forming Machines

1. Automation Modern metal strut channel roll forming machines are equipped with advanced automation features, enabling high-speed production with minimal manual intervention. This not only increases output but also reduces labor costs and the potential for human errors.

2. Precision Engineering These machines are designed to achieve precise dimensions and tolerances. This accuracy is essential for ensuring that strut channels fit seamlessly with other components in a construction project, enhancing structural integrity.

3. Versatile Production Manufacturers can easily adjust the machine settings to produce different channel sizes and shapes, allowing for the production of custom solutions. This versatility is particularly valuable in projects that require unique specifications.

4. Durability and Maintenance Given the rigorous demands of the construction environment, roll forming machines are built to withstand high levels of stress and wear. Regular maintenance can ensure longevity and consistent performance, making them a wise investment for manufacturers.

Benefits to the Construction Industry

The metal strut channel roll forming machine brings numerous advantages to the construction sector. First and foremost, it boosts productivity, enabling manufacturers to meet tight deadlines. With faster production cycles, construction projects can progress on schedule, reducing downtime.

Secondly, the high level of precision achieved through roll forming leads to better quality products, resulting in fewer on-site installation issues. This reliability enhances overall project efficiency and reduces waste.

Lastly, the use of strut channels produced by roll forming machinery contributes to sustainable building practices. The machines can utilize recyclable materials, and the efficient production process minimizes scrap, aligning with green building initiatives.

Conclusion

The metal strut channel roll forming machine is a key player in the contemporary construction industry, facilitating the efficient and accurate production of vital structural components. As construction projects grow in complexity and scale, leveraging advanced manufacturing technologies like roll forming not only enhances productivity but also supports the delivery of high-quality structures. For any manufacturer or contractor aiming to optimize their operations, investing in this machinery is a strategic move towards modern, efficient construction practices.