The Importance of Metal Storage Racks and Upright Pillar Roll Forming Machines

In the realm of modern warehousing and inventory management, the significance of efficient storage solutions cannot be overstated. One of the most effective options available today is the metal storage rack. These structures are indispensable for businesses seeking to optimize space, improve organizational efficiency, and enhance the safety of stored goods. Furthermore, the manufacturing process of these racks is equally crucial, and this is where upright pillar roll forming machines come into play.

Understanding Metal Storage Racks

Metal storage racks are robust frameworks designed primarily for the storage of goods in warehouses and distribution centers. Unlike conventional storage solutions, metal racks offer a multitude of benefits, including durability, adaptability, and structural integrity. They can support a wide range of products, from heavy machinery and equipment to light packaging materials, making them suitable for various industries such as retail, manufacturing, and logistics.

The use of metal ensures that these racks can withstand the rigors of heavy loads and frequent use. Their design can be customized to meet specific storage needs, with options ranging from selective racks to drive-in racks, pallet flow systems, and shelving units. This versatility allows businesses to maximize vertical space and enhance inventory management, leading to increased operational efficiency.

The Role of Upright Pillar Roll Forming Machines

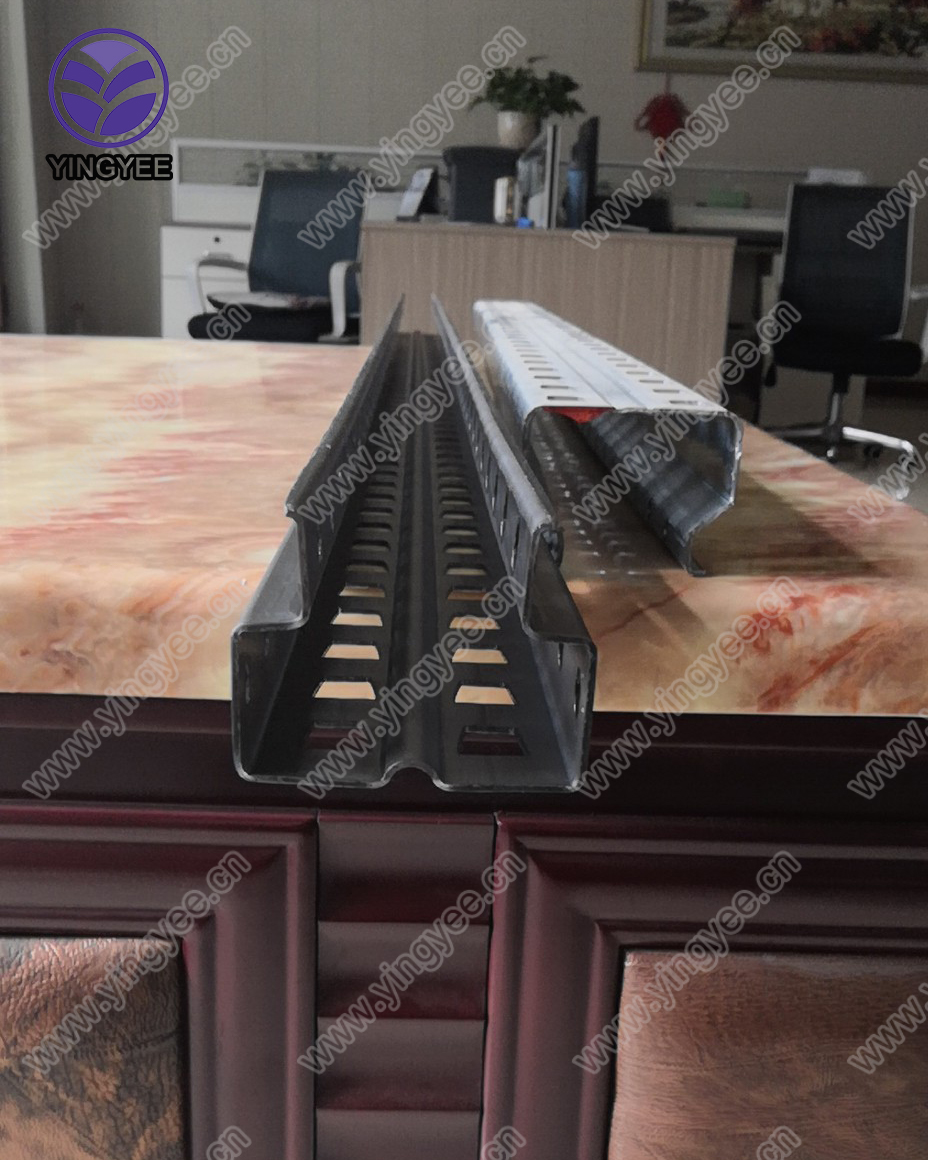

The manufacturing of metal storage racks involves sophisticated processes that can greatly influence the quality and efficiency of the final product. This is where upright pillar roll forming machines come into the spotlight. These specialized machines are designed to create upright pillars that form the backbone of metal storage racks.

Upright pillar roll forming machines operate on a principle of continuous bending and shaping of metal sheets into desired profiles. The process involves feeding metal sheets through a series of rollers that progressively shape the material. This technology enables manufacturers to produce upright pillars with precise dimensions and structural characteristics that meet stringent industry standards.

The use of roll forming machines offers several advantages over traditional manufacturing methods. Firstly, they provide a high level of precision, ensuring that every upright pillar is uniform and meets the necessary specifications. This uniformity is essential for the structural integrity of the racks, as any discrepancies can lead to instability and safety hazards.

Secondly, roll forming is a highly efficient process that allows for high-speed production. This means that manufacturers can produce large quantities of upright pillars in a shorter amount of time, reducing lead times and improving overall productivity. Furthermore, the automation of the roll forming process minimizes labor costs and the potential for human error, enhancing both the efficiency and quality of production.

Lastly, the versatility of upright pillar roll forming machines means they can accommodate various metal materials, including cold-rolled steel and galvanized steel, to cater to different storage rack requirements. This adaptability not only supports customization but also ensures that the resulting storage racks can meet specific environmental conditions, such as corrosion resistance or load-bearing capacity.

Conclusion

In conclusion, the significance of metal storage racks in modern inventory management cannot be ignored. They play a vital role in enhancing storage solutions across various industries. Paired with the innovative technology of upright pillar roll forming machines, manufacturers can produce high-quality, reliable products that meet the growing demands of businesses today. Investing in effective storage solutions and advanced manufacturing processes not only enhances efficiency but also positions companies for future growth in an increasingly competitive market. As the industry continues to evolve, the importance of both metal storage racks and the machinery used to create them will undoubtedly remain a cornerstone of effective inventory management.